The violent contrasts between dry and wet weather of recent months have laid bare the urgent need to build, maintain and upgrade water management infrastructure. This article examines how we can adapt natural recycling can help conserve this vital resource, how we can build more resilient systems to manage our water, and how stainless steel is vital to that goal.

By James Chater

Scarcity

In 2009 I wrote: “We are failing to manage our global water resources. This is not because of a lack of water as such. Rather, it is because rising populations and expanding economies on the one hand and environmental degradation (much of it due to global warming) and lack of investment on the other are placing intolerable pressure on water resources.” (1)

Today, 13 years later, I would not change a word. The two interconnected problems remain: water scarcity caused by inefficient handling of the resource and by climate chaos, and inadequate wastewater treatment systems.

It is not for lack of initiatives and projects. The problem is that global warming has worsened at a faster rate than the steps being taken to tackle the problems.

The extreme heat and drought of this summer, followed by the devastating floods in Pakistan, are symptoms of this. After a prolonged drought, the earth is unable to absorb rain, so there are run-offs and flash floods once the rain begins. In poorer countries, wastewater is not being treated properly, and poor sanitation is causing the deaths of 800 children a day(2).

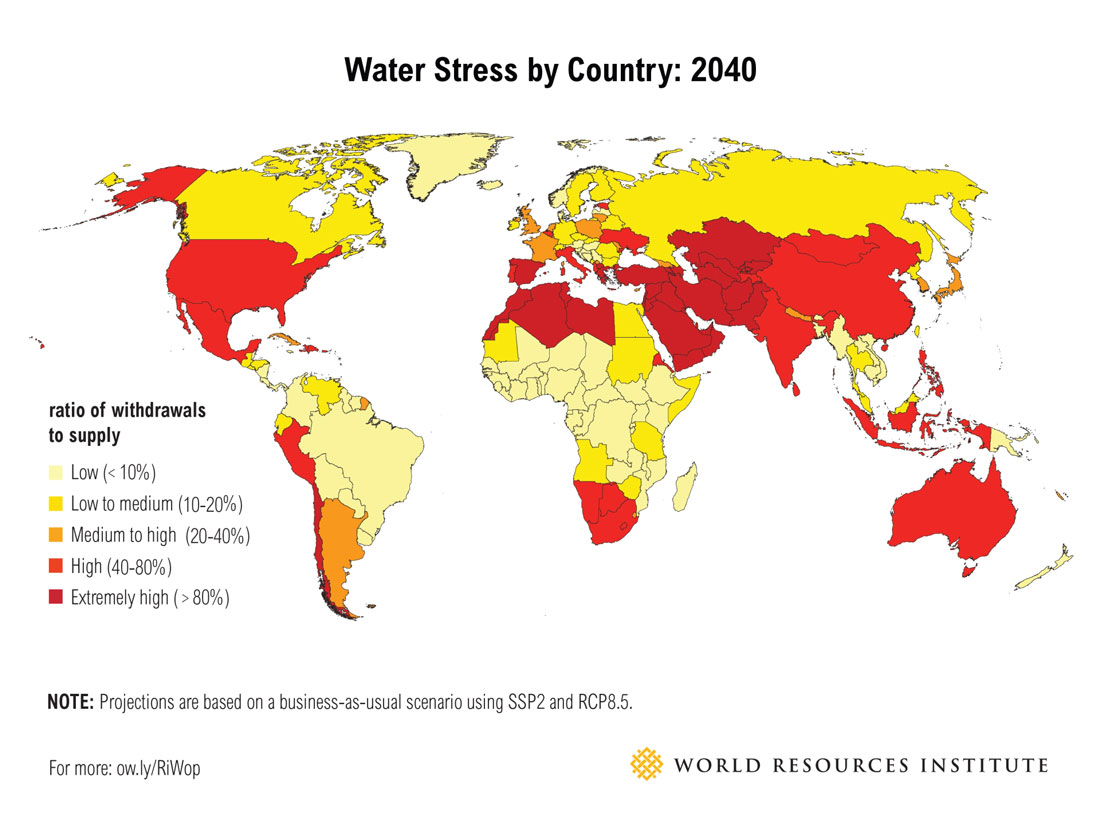

Unsurprisingly, the worst droughts occur in northern Africa and the Middle East, but the situation in Greece and Spain is equally alarming (see map). Among industrial countries, the USA, China and India are also major drought regions, which could affect the global economy. Apart from drinking, water is essential to industry, agriculture and power generation. Its absence is felt

in countries that rely on water-cooled nuclear reactors to generate electricity. So what can be done? There are at least five overlapping areas where measures are being taken:

1 recycling;

2 savings and economies of both water and power;

3 expansion & updating of wastewater treatment;

4 improved quality and quantity of drinking water;

5 improved flood management.

Recycling

Recycling is a natural process (rain, run-off, evaporation, cloud formation, rain…) that has been disrupted by climate change. Because of this disruption and population pressures, it has become necessary to create shorter recycling processes and “closed loops” wherever possible.

The scope for recycling is considerable, as several applications do not require water of drinking quality. This “grey” water can serve for irrigation, e.g., watering, street cleaning, car washing or industry. But it is possible to go further, treating used water for drinking purposes. This already happens in the world’s driest reasons, notably Israel, which recycles 90% of its water. Now Spain and France are following suit. Veolia is currently installing wastewater recycling units at all its sewage treatment plants in France. Its Jourdain recycling project will soon secure drinking water supplies for the Vendée’s inhabitants.

Recycling also works within buildings: by collecting rainwater and recycling wastewater in a closed circuit, waste can be greatly reduced. Such closed loops are being installed in a Nestlé factory in Mexico and the Pearl gas-to-liquid complex operated by Shell in Qatar.

Brexit and sewage

The UK’s sewage problem has literally raised quite a stink. Beaches and rivers have been polluted to an extent rarely seen in advanced industrial countries. This occurred after the UK government relaxed the rules governing discharge of wastewater into the environment. Companies are now allowed to discharge water that has been only partially treated. The rules were part of the UK’s obligations under EU law, which since Brexit no longer apply. The crux of the problem is that certain chemicals required in wastewater treatment are in short supply. One of these is ferric sulphate, an acid that removes phosphorus and prevents the growth of algae. The reason for the shortages is that HGV drivers are increasingly reluctant to drive between the UK and the EU because of the red tape that exists as a consequence of the UK leaving the EU.

Economies and maintenance

Throughout the world, an alarming amount of water is lost each day because of leaks. Corrosion-resistant stainless steel and leak-free valves are essential in the battle against this waste. But it is not only water that needs to be saved. Water management is energy-intense, mainly because of the pumps required. Compression exchangers can save a great deal of energy by recovering heat from brine in seawater RO desalination facilities. Cumwhinton, near Carlisle in the UK, is the first treatment plant to install UV LED reactors to reduce energy costs. Water companies are harnessing solar power and other renewable energy types to run their plants. Veolia and TotalEnergies have partnered to build a large solar-power system for a desalination plant in Oman.

Wastewater treatment

Over the world, urbanisation and increasing population are driving wastewater treatment projects. Even in the UK, despite the negative news about sewage discharges (see box), a number of upgrades of sewage plants have recently been carried out. At Bicester, a predicted increase in population induced Thames Water to build an activated sludge plant and filter beds. At Burnley, the wastewater works have been refurbished, including a detention tank and pumps, primary settlement tank, activated sludge plant, power upgrade and more.

Drinking water

Apart from recycling, a good way to conserve drinking water is by preventing leaks. To this end, secondary water supply systems bringing water from mains to tap are an ideal candidate for stainless steel type 316L, as shown by a refurbishment project in Shenzhen, China, where the grade was applied to prevent corrosion and contamination. In the dry countries that can afford it, desalination, which is expected to grow in revenue by 9.32% from 2021-6, will be a fast-growing source of drinking water. Some very large plants are being built in the Middle East, especially on the Arabic peninsular, with a variety of duplex stainless steels being applied to resist the saline conditions.

Water and energy

Apart from being essential to sustain life, water can be harnessed to produce energy. Hydropower is the most obvious example of this, but there are others. As part of the renovations to the Dutch flood barrier, the Afsluitdijk, a system is being installed that can generate electricity through the convergence of saltwater and freshwater (osmotic power). Scientists are also researching ways of harnessing the kinetic energy of raindrops to produce electricity. This can be tapped using certain materials with piezoelectric properties (that generate electricity in response to applied mechanical stress).

Flood control

An increasingly important element of water management, especially in urban areas where built-up surfaces prevent run-off, is flood control. The installations can be sophisticated, as in Glasgow’s Smart Canal, a dynamically managed system that accepts stormwater run-off via three discharge locations controlled by actuated sluice valves and controls discharge flow into a nearby river. One of the largest of such systems is the recently completed Dubai Deep Storm Tunnel System, which caters for 40% of the urban area. It comprises a groundwater and stormwater collection network, a 10km-long deep tunnel, a holding pond, a pumping station, and a sea outfall. Ham Baker is installing what may be the world’s biggest and highest penstocks, made in duplex S32750.

Materials

In new water treatment and management systems, stainless steel has superseded carbon steel, cupronickel and other materials in many applications. The advantages in terms of weight (allowing greater thinness and lighter, easier-to-manage structures), corrosion/erosion resistance and hygiene are too great to ignore. The most important trend in recent years has been the increased use of duplex stainless steels compared to austenitics. This is most evident in desalination, and companies such as Outokumpu offer a suite of duplex grades to cater for the different conditions in each plant. A recent example is an MSF desalination plant recently built by Fisia Italimpianti, for which Outokumpu supplied both Forta DX 2205 and the milder lean grade Forta LDX 2101 for two different applications within the evaporation chambers.

In non-desalination applications, too, lean duplex is set to gain market share. Veolia and two stainless steel makers, Aperam and Outokumpu, have collaborated with the French Corrosion Institute to study the role lean duplexes could play. According to an independent study, Aperam’s DX2202 (1.4062) lean duplex offers the same level of corrosion resistance as 316L in wastewater applications. A similar grade is Nippon’s NSSTS2351, developed as an alternative to 316L to handle brackish water. Forta LDX 2101 has also been applied in a new storage tank design by Invest-Tech. These tanks dispense with the traditional round shape, being built in square or rectangular segments to allow expansion.

References

(1) Stainless Steel World, January/February 2009.

(2) https://www.oxfam.org/en/what-we-do/issues/water-and-sanitation.

About this Featured Story

This Featured Story appeared in Stainless Steel World November 2022 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE) .

Want to contribute as author? Please contact Joanne.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.