The stainless tubes and pipes sector serves a number of industries that are currently experiencing remarkable growth. Companies are expanding and updating to take advantage of the opportunities.

By James Chater

Strong growth

The current economic uncertainty has left the tube, pipes and fittings sector relatively unscathed. On the whole, the post-Covid economic recovery – though weak because of inflation and the ongoing war in Ukraine – provides a positive environment, with certain regions and sectors driving growth. The global stainless-steel tubes and pipes market, estimated at USD 32 billion in 2021, is anticipated to grow to 44.7 billion in 2028, with an annual compound growth of 4.6% (1). Growth in Asia as usual leads the pack, and one country has seen spectacular growth in its steel tube and pipe manufacture: India. Half of India’s steel tube and pipe sector is stainless, with companies such as Scoda and Venus Tubes and Pipes leading the way in terms of organic growth. These gains come despite massive increases in nickel prices and mounting energy costs, at least in Europe.

Also, those companies that publish their results have largely performed well in 2022, and many have ambitious investment plans. Tubacex, which exceeded its 2019 results in the first nine months of 2022, is increasing its revenue in the oil & gas sector and investing in CO2 capture and storage (CSS). Ukraine-based Centravis, despite the uninvited guest on their home territory, is increasing CAPEX by USD 10 million in 2022. Maruichi (formerly Kobelco) is expanding its capacity in its semiconductor, hydrogen and auto sectors and has opened a subsidiary in the USA; Maruichi Stainless Tube Texas. Phoenix Tube is investing USD 8.1 million at its plant in Bethlehem, USA, with new production line for small-diameter stainless steel, titanium, and nickel alloy pressure tubing used by the construction industry.

Butting pipes are transported by rail, ship and truck all over the world.

Inside a tube mill of Alleima (formerly Sandvik Material Technologies).

Markets

Oil & gas

The oil & gas sector remains crucial for the tubes & pipes sector, with special dynamism shown in Guyana and great promise in new fields in Turkey, Suriname, Tanzania and Namibia. Oil & gas companies were spectacularly profitable in 2022, and this is likely to continue even if prices are expected to moderate after the spike of 2023 (according to the US Energy Information Administration). Orders for stainless tubes and pipes have been pouring in. Alleima (formerly Sandvik Materials Technology) reported an order of USD 23 million for umbilicals. Tubacex has been supplying Exxonmobil’s Guyana offshore and landed a large award from ADNOC in Abu Dhabi for CRA OCTG products, where they are building a plant that will open in 2024. Butting delivered duplex (LC65-2205/UNS S31803) welded pipes to a Middle Eastern company, and Petrobras awarded important contracts to Tenaris and Vallourec, who also won an order from Saudi Aramco for OCTG products. Fine Tubes supplied high-performance tubes in MONEL® alloy 400 for Qatargas’s oil & gas industry.

Petrochemicals and chemicals

Petrochemicals and chemicals are also a dynamic market for the high-end special alloys and higher grades of stainless steel. The petrochemicals industry, valued at USD 37.5 billion in 2021, is projected to grow at an annual compound growth of 8.5% between 2022 and 2028 (2). However, the short-term predictions for the US chemicals industry are for a mild recession in 2023, caused partly by inflation – especially of fossil fuel prices. Duplex and carbon steel are the two most used types of material for pipes. Duplex is finding increasing use in heat exchangers, transport, cooling pipes and structural components.

Sustainability and circularity (recycling) are concepts that will grow ever more important, especially in the petrochemicals industry. One waste-to-energy process, for instance, relies on pyrolysis (burning in the absence of air) for the conversion process. The tubes and vessels use materials selected for their oxidation resistance, high strength, thermal cyclic resistance, creep properties and carburisation/crack resistance. These include such grades as the austenitics 253 MA, 309, 310S and 330, and INCONEL 610. To these we may now add Alleima’s Sanicro® 35 grade. In June 2022, the company announced that it had received an order from a waste-to-gas plant in Texas to replace failed heat exchanger tubes in 316L with its new alloy.

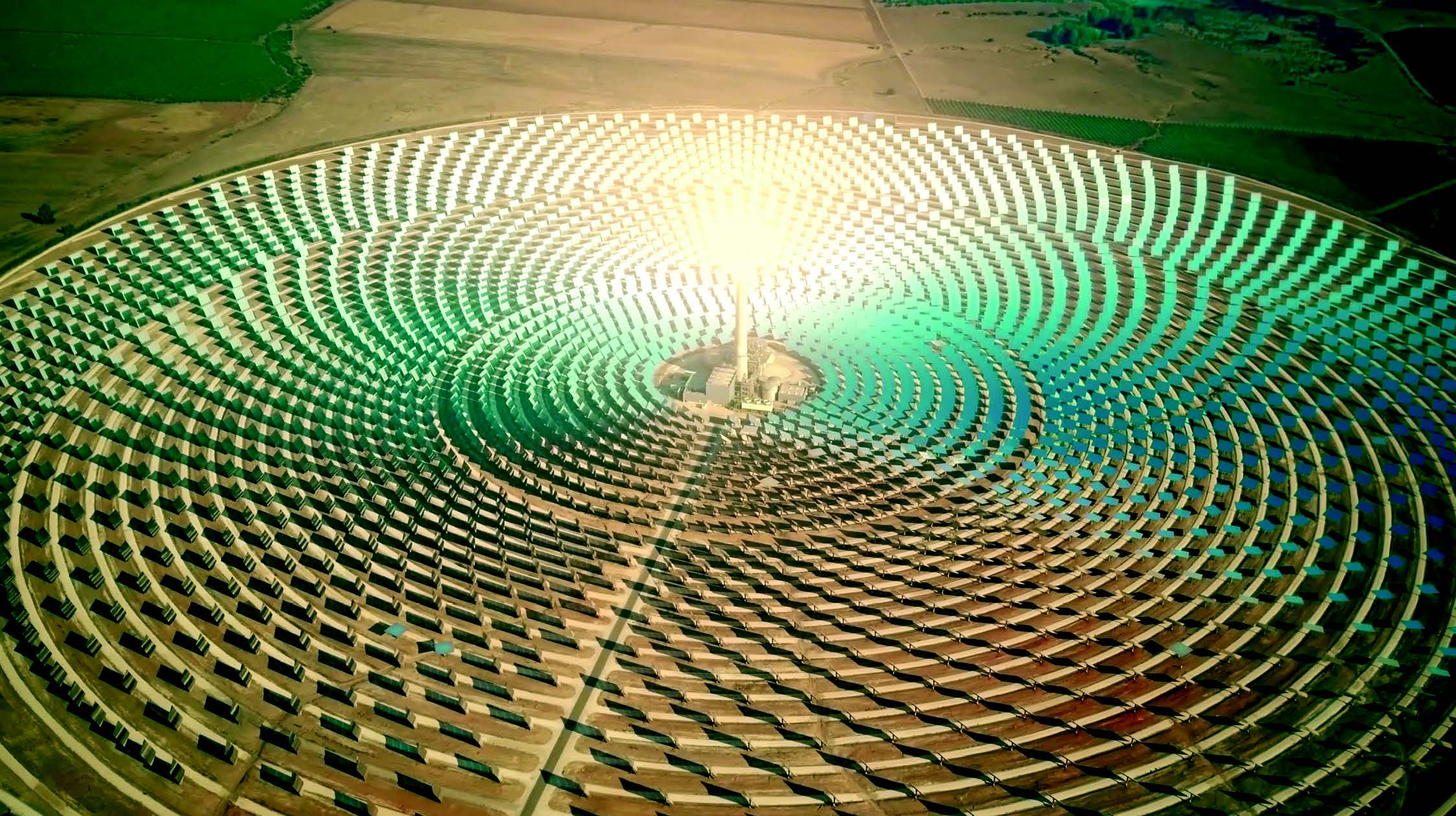

Gemasolar concentrated solar power plant in Fuentes de Andalucía, Spain, utilises a molten salt heat storage system.

CCS

The CCS industry was estimated at USD 4.2 billion in 2022, and demand is expected to surge to 9 billion by 2032, with an annual compound increase of 14% (3). The processes require transportation pipelines that can withstand a wide range of pressure and temperature levels. High levels of corrosion resistance and toughness, as well as rigorous welding requirements, are needed to resist thermal shocks or extreme cooling, which can cause pipes to crack or rupture. Vallourec, Maruichi and Alleima are all suppliers of CCS tube and pipe products, while Tubacex is developing industry-specific solutions. For instance, Alleima has just received an order of OCTG tubes to be used in a CCS project.

Hydrogen

The outlook for hydrogen is even more astonishing: the green hydrogen sector is worth USD 676 million (in 2022) and is expected to grow to 7,314 million by 2027, a projected 61% rate of annual compound growth (4). More than 200 hydrogen projects are in progress around the world, and demand is coming mainly from power generation, chemical and transport. The importance of hydrogen is not lost to Alleima, who recently acquired Gerling, the German maker of precision tubes and owner of high-pressure control technology used in H refuelling stations. Hydrogen is usually transported in compressed or liquid state. With a boiling point of -252.9°C, hydrogen requires pipes and vessels made of an austenitic that can withstand cryogenic conditions, usually 316(L). The steam reforming process for “grey” hydrogen also uses nickel alloys.

Semiconductors

Semiconductors were in short supply in 2021-2. Since then, the situation has eased in consumer electronics but persists for certain industries, especially auto. The industry is very global, with different components coming from different locations and a great deal of interdependence. Manufacture is concentrated in China, Taiwan and South Korea, but more capacity is being built in the USA, Thailand and Mexico. Because of the demands of cleanliness and high-precision instrumentation, semiconductor plants are very difficult to construct. Regarding tubes, the requirements are rigorous: resistance to stress cracking and corrosion, mechanical strength, and cleanliness. Maruichi is investing in Texas, USA, and its Shimonoseki plant in Japan to manufacture the bright annealed tubes required in semiconductor manufacture.

Power Generation

Most of the current power generation growth comes from renewables. According to the IEA, renewables will surpass coal as the largest source of electricity generation by early 2025. One of the major applications for stainless-steel pipes are the receiving pipes used in concentrated solar power (CSP). These contain molten salt and most withstand temperatures up to 500 °C. Austenitics such as 321 and 347H have been used, but more recently, Inconel 625 has been applied for its greater creep resistance and oxidation/corrosion resistance.

Although we associate renewables above all with solar and wind, among the most promising sectors is the relatively small one of geothermal energy. This market is projected to grow from USD 62.65 billion in 2022 to USD 95.82 billion by 2029, with a compound annual increase of 6.3% during the forecast period (5). It is also the sectors that requires the most corrosion-resistant of all alloys, materials such as duplex, super austenitics and nickel alloys such as 625 and 825.

The technology is changing fast, which could affect the growth rate. Vallourec has teamed up with GreenFire Energy to develop a closed-loop system consisting of thermally insulated pipes that harvest underground heat and bring it to the surface (as hot water or steam) with minimal losses.

Another energy sector that could potentially grow faster is nuclear fission. Under pressure to find alternative energy sources after halting oil & gas imports from Russia, the EU recently reclassified nuclear as a “transition” energy. Germany is delaying the closure of the nuclear plants it said it would shut down. India is expected to build several new reactors soon, and its programme includes fast neutron reactors and the use of thorium as a fuel.

Drinking water

With increasing urbanisation comes greater demand for water supply systems. The demand for secondary water systems (from main to meter, and from there to the private residences) that transport water into apartment buildings has been increasing for some time. From 2019, China has been extensively upgrading its systems

in three stages, the first of which is 2019-23. In the pipes, galvanised steel, ductile iron or plastic have given way to stainless after the earlier types were found to be prone to leaks. Shenzhen, in overhauling its water system, opted for 316L in all tubes, fittings and water tanks in secondary systems, and other municipalities have been following suit. In coastal regions, 316L will be preferred because of the saline conditions, but in low-chloride conditions 304 is acceptable. Exceptionally, if the water is salty (chloride level >1000 ppm), duplex or superaustenitic grades are required.

Automobile

This industry has recently been vulnerable to supply chain issues, one of the reasons, aggravated by Brexit, that the UK has suffered a catastrophic decline in production and market share. Although electric vehicles are the most rapidly growing part of this sector, the internal combustion vehicle will not disappear overnight, ensuring that stainless steel demand will remain significant.

Stainless tube requirements in auto include exhaust pipes, which are usually made of ferritic. There are also applications in which austenitics are standard: chief among these is gasoline direct injection (GDI) tubing, which improves efficiency by reducing weight. Stainless tubing is also used in transmission systems, for coolant circulation, and in impact absorbers frames and bumpers.

References

About this Featured Story

This Featured Story appeared in Stainless Steel World April 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE) .

Want to contribute as author? Please contact Joanne.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.