During a recent routine maintenance shutdown, extended lead times and supply chain delays on traditionally manufactured parts challenged Chevron’s planned restart schedule.

Text & images by Lincoln Electric

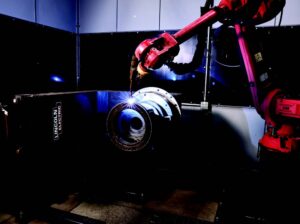

Chevron’s Additive Engineering team worked with Lincoln Electric to get back on schedule using additive manufacturing to print critical replacement parts that would meet production and quality standards. Lincoln Electric has utilised its proprietary large-scale, metal 3D printing solution to deliver just-in-time parts to Chevron USA, Inc. to help bring a petrochemical refinery back online.

Supply chain crunch

“Our planned maintenance schedule was in jeopardy due to current supply chain issues,” said Robert Rettew, Materials Technology Engineer. “We realized this supply crunch could impact operations and our bottom line.”

The company needed to find a solution and explored how parts could be created faster so that plant operations could resume as planned.

The two teams worked together, along with industry experts from Stress Engineering Services, Inc., to print eight nickel alloy replacement parts that averaged approximately 3 ft. (0.9 m) in length and over 500 lbs. (226 kg) each in a total of just 30 days.

Just-in-time production

“We are pleased to work with Chevron and showcase the value of just-in-time production using additive manufacturing, and its ability to prevent facility downtime,” said Christopher L. Mapes, Lincoln Electric’s Chairman and CEO.

“Metal 3D printing for large-sized metal parts, moulds, tooling and prototypes is a game-changing solution for various end markets, including industrial manufacturing, energy and aerospace. When speed-to-market, design flexibility and reduced costs take priority; our printing technology provides the ultimate answer.”

As the largest known, wire metal 3D printing factory in the world, Lincoln Electric’s additive manufacturing solution for high-mix, low-volume applications is capable of printing metal-based parts up to 7 ft.

(2.1 m) in length and weighing in excess of 5,000 lbs. (2,265 kg).

This innovative technology significantly reduces manufacturing lead times, shortens supply chains, and enables design enhancements that exceed traditional fabrication capabilities.

Based in Cleveland, Ohio, Lincoln Electric’s proprietary and patented metal 3D printing solution utilizes its own SculptPrint™ software, robotic cells and welding wire to control quality and ensure a reliable supply chain.

About Lincoln Electric

Lincoln Electric is a leader in the engineering, design, and manufacturing of advanced arc welding solutions, automated joining, assembly and cutting systems, plasma and oxy-fuel cutting equipment.

To learn more about the measurable value of large-scale 3D metal printing, visit https://additive.lincolnelectric.com/.