Article by Joanne McIntyre

___

International project

The 200-metre-long PIP-II accelerator is the first accelerator project built in the United States with significant contributions from international partners. The UK Government is supporting the development of key components and TWI is working with the Science and Technology Facilities Council (STFC) through their Daresbury facility to develop the crucial cryomodules at the heart of the accelerator.

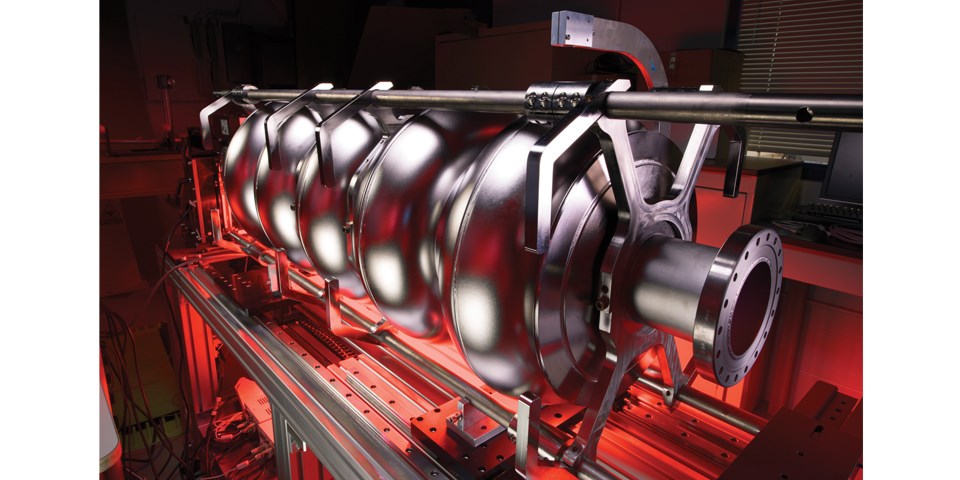

The core of the cryomodule is an RF cavity, approximately 1.4m long and made of a complex series of high purity niobium components which are joined by high integrity electron beam (EB) welding.

TWI is leading a collaboration to make these critical components, working with Shakespeare Engineering, Chelmsford who will form the parts and the NAMRC who will support development of the procedures. The project will see TWI installing a state of the art dry-pumped electron beam welding machine with a capability to operate under cleanroom conditions.

What is LBNF/DUNE?

Hosted by the U.S. Department of Energy’s Fermilab, the Long-Baseline Neutrino Facility and Deep Underground Neutrino Experiment is an international project bringing together more than 1,000 scientists from over 30 countries, all dedicated to unraveling the mysteries of ghostly particles called neutrinos. To do this, Fermilab will send its particle beam 800 miles (1,300 kilometers) through the earth to four gigantic detectors built a mile beneath the surface at the Sanford Underground Research Facility in South Dakota.

The beams will be created with particle accelerators located at Fermilab in Illinois. The DUNE detectors will be housed in caverns at the Sanford Underground Research Facility in South Dakota. These supersensitive detectors will contain almost 70,000 tons of liquid argon to record neutrinos with unprecedented precision.

World-class EB facility

The opportunity for UK industry to engage in large, prestigious Big Science programmes is an end in its own right. However the installation of a world-class high vacuum electron beam welding facility is an enabling capability which is available for use by industry in the development and manufacture of high value assemblies, including niobium assemblies for space and the medical sector, titanium for use in satellite propellant tanks and zirconium for power applications. Through TWI, UK industry can take full advantage of this exciting new facility.

All about Niobium: 41Nb

Niobium, formerly known as columbium, is a chemical element with symbol Nb (formerly Cb) and atomic number 41. It is a soft, grey, crystalline, ductile transition metal, often found in the minerals pyrochlore and columbite, hence the former name “columbium”. The German chemist Heinrich Rose determined in 1846 that tantalum ores contain a second element, which he named niobium. In 1864 and 1865, a series of scientific findings clarified that niobium and columbium were the same element (as distinguished from tantalum), and for a century both names were used interchangeably. Niobium was officially adopted as the name in 1949, but the name columbium remains in use in the US.

Niobium is used mostly in alloys, the largest part in special steel such as that used in gas pipelines. Although these alloys contain a maximum of 0.1%, the small percentage of niobium enhances the strength of the steel. The temperature stability of niobium-containing superalloys is important for its use in jet and rocket engines. Niobium is used in various superconducting materials. These superconducting alloys, also containing titanium and tin, are widely used in the superconducting magnets of MRI scanners. Other applications of niobium include welding, nuclear industries, electronics, optics, numismatics, and jewelry. In the last two applications, the low toxicity and iridescence produced by anodization are highly desired properties. Niobium is considered a technology-critical element.

Sources

CERN https://cds.cern.ch

Fermilab https://lbnf.fnal.gov

Wikipedia https://en.wikipedia.org/wiki/Niobium