The Kawasaki plant of Nippon Yakin Kogyo.

For almost a century, Nippon Yakin Kogyo (Nippon Yakin) has produced stainless steel and high-end nickel alloys for some of the world’s most demanding applications. The company continues to expand its high-performance materials business by enhancing its product range, development of new materials, and investments in state-of-the-art equipment. Stainless Steel World visited to learn about recent milestones, including the new offering of ultra-wide nickel alloy plates for the Chinese market and the highly corrosion resistant nickel alloy NAS355N.

By Kiyo Ichikawa & Joanne Mcintyre

Nippon Yakin is a Japanese mill manufacturer with a long history, dating back to 1925. Today , the company manufactures and supplies strip and plate in a wide range of materials, from general-purpose stainless steels such as type 304 and type 316L to high-performance materials such as super stainless steels and nickel alloys. In particular, the company sells more than 10,000 tons of nickel alloy flat products per year, and in recent years has maintained its position among the world’s top three nickel alloy producers.

Recent developments

In the stainless steel and speciality steel industry, demand for both consumer and industrial applications fell sharply in the first half of 2020 due to the COVID19 pandemic. However, the market recovered gradually in the second half of the year. China’s high-performance materials sector was the first to show recovery from the effects of the pandemic, and some demand (for example, in the solar photovoltaic industry) has fully recovered. There were also signs of new decarbonisation related demand, particularly in Europe. However, due to the prolonged lockdowns in many countries, environmental equipment and oil and gas sectors overseas remained weak.

In this environment, Nippon Yakin took advantage of a partial recovery in demand, maintained metal spreads for general-purpose stainless steels and tried to shorten lead times for high-performance materials while implementing thorough cost-cutting measures. As a result, the company was able to secure a profit of approximately 5 billion yen (EUR 38.5 million).

Extra-wide nickel alloy plates

Nippon Yakin is utilising a joint venture company, Nisco Nippon Yakin Kogyo Nanjing Co., Ltd., with its partner, Nanjing Iron and Steel Co., Ltd., to enhance its product range. For example, in 2020, using the wide hot rolling mill of Nanjing Iron and Steel, it successfully manufactured 3270mm wide plate products of NAS800T (UNS N08811), a highly heat resistant nickel alloy. In June this year, the company also succeeded in producing a 3510mm wide plate of NAS625 (UNS N06625), a highly corrosion resistant and heat resistant nickel alloy.

The high temperature strength of these alloys makes it difficult to manufacture wide width products. However, with the cooperation of Nanjing Iron and Steel and the know-how of Nippon Yakin, the project was successful. The wide width of the plate reduces the number of welding points required during the manufacture of equipment, thus contributing to shorter delivery times and lower costs for the fabricator in the equipment manufacturing stage. The main focus of this development is to expand sales of high-performance alloy plates to China. NAS800T wide plate material was sold to Chinese customers for use in reaction tubes for ethylene plants in October 2020. Nippon Yakin also plans to commercialise wide plates in other alloys and focus on expanding sales to China.

Nickel alloy NAS355N

An important milestone in 2020 was the development of NAS355N, a highly corrosion resistant nickel alloy with excellent corrosion resistance in chloride and sulfuric acid environments. NAS355N is a seeds-type new alloy, which has been specifically designed to fill the gap between super stainless steels and nickel alloys such as alloy C-276 , and is successfully manufactured into 4ft wide coils. This alloy is expected to be utilised in environmental equipment and chemical plants.

Strategic capital investments

Nippon Yakin continues to execute strategic capital investments to maintain its position as one of the world’s top three nickel alloy manufacturers. The construction of a new electric furnace at the Kawasaki Plant is progressing smoothly, and it will start operation in January 2022. Once completed, the facility will be highly efficient and provide an improved working environment. In addition, remodelling and upgrading the slitting line (scheduled for completion in May 2023) is part of the expansion of the facilities in the cold-rolling shop to ensure it meets the increasingly sophisticated needs for processing precision.

New wastewater processing facilities installed at the Kawasaki Plant started operation in October 2020 to reduce the risk of environmental pollution and strengthen stable operations. In March 2021, the electrostatic precipitation facilities at the Oeyama Plant (ferronickel production base) were partially renewed to strengthen environmental measures and stabilise operations.

In August 2021, the company established a Sustainability Strategy Promotion Committee to further its efforts in addressing the strong demand for sustainability development goals (SDGs), environmental social and corporate governance (ESG) issues, and carbon-neutral efforts.

Expansion of sales of high-performance materials

Materials for environmental applications (for example, SOx scrubbers for ships, fuel gas desulphurisation equipment) have been a key focus for Nippon Yakin since the start of its medium-term management plan 2020. Given the global trend towards decarbonisation, renewable energies and hydrogen stations are promising sectors requiring high-performance materials.

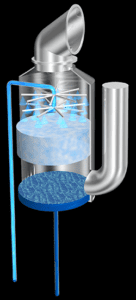

SOx scrubber for ships

Stricter environment regulations to remove sulfur oxide (SOx) from ship’s exhaust gases has led to a surge in the installation of SOx scrubbers. In these scrubbers, the exhaust gas is washed in a shower of seawater to reduce SOx. Therefore, the inside of the scrubber is a sulphuric acid environment containing seawater, which is corrosive to general-purpose stainless steel. Highly corrosion resistant materials such as duplex and super duplex stainless steel, super austenitic stainless steel, and nickel alloys are required. The scrubber manufacturer’s design and the area of use will determine the appropriate material to select.

Nippon Yakin offers duplex stainless steel NAS64 (UNS S32506), super duplex stainless steel NAS74N (UNS S32750), super austenitic stainless steel NAS185N (UNS S31254), NAS254N (UNS S32053), NAS254NM (UNS N08367), NAS255NM (UNS N08926) and the highly corrosion resistant nickel alloy NASNW276 (UNS N10276). It produces a full range of products to meet the demands of scrubber manufacturers and fabricators.

The International Maritime Organisation (IMO) is enforcing the SOx regulation in stages and extended the regulated area to the whole world in 2020. Demand for SOx scrubbers peaked in 2019 and 2020 but will remain strong over the next few years as existing ships are retrofitted, and new ships are fitted with scrubbers.

FGD: fuel gas desulfurisation

Coal fired power stations are equipped with fuel gas desulphurisation (FGD) systems to reduce SOx in the combustion exhaust gas as a pollution control measure. The inside of the fuel gas desulphurisation plant contains high levels of chlorine from the fuel (coal). It is an acidic environment which is harsh for general-purpose stainless steel. For this purpose, super duplex stainless steel NAS74N (UNS S32750), super austenitic stainless steel NAS254N (UNS S32053), NAS254NM (UNS N08367), NAS255NM (UNS N08926) and highly corrosion resistant nickel alloy NASNW276 (UNS N10276), all of which have high corrosion resistance, are used.

In the context of the decarbonisation trend, the coal fired power sector is an area that will shrink quickly; however, demand for maintenance will continue for some years to come.

Oil and gas industry

In the long term, the oil and gas industry is likely to shrink due to the global decarbonisation trend, but demand is expected to continue in the medium to short term. Major projects postponed in 2020/2021 due to the pandemic are restarting and will accelerate in the coming months.

In this industry, various high-performance materials are required, depending on the environment of the oil and gas fields. NAS825 (UNS N08825), a highly corrosion resistant material, has sufficient corrosion resistance for oil and gas fields which are highly corrosive due to the presence of hydrogen sulfide (H2S) and carbon dioxide (CO2). It is used in pipelines transporting crude oil and gas and in pipes protecting hydraulic control cables and sensors. It is also in demand for process components such as air fin coolers. NAS625 (UNS N06625), which is more corrosion resistant than NAS825 (UNS N08825), is in stable demand for pipeline and oil refinery components used in harsher environments. NASNW400 (UNS N04400) is specified for offshore installations.

Nickel alloys for renewable energy

As the trend towards decarbonisation accelerates, renewable energy

is providing opportunities for manufacturers of high-end alloys such as Nippon Yakin. Photovoltaic power generation is one of the most common renewable energy sources, using solar cells to convert light energy directly into electricity. Polycrystalline silicon is a raw material for solar cells. The Siemens process, which is a typical method of producing polycrystalline silicon, includes the reaction of metallic silicon with hydrogen and chlorine at high temperatures (approximately 500°C) and under high pressure. The highly heat resistant nickel alloy NAS800H (UNS N08810) is used in the reaction vessel for this process.

In recent years, polycrystalline silicon producers have sought to increase the size of their equipment to improve productivity. However, the corresponding increase in plate thickness has led to disadvantages for the equipment manufacturer regarding the cost and workability of the plate material. Therefore, NASH38X (UNS N08120), a highly heat resistant nickel alloy with even better high temperature properties than NAS800H, is increasingly used to overcome the disadvantages of cost and workability. Sales of both alloys to China have been strong, with demand expected to remain robust.

Another example of a high-performance material applied for renewable energy is geothermal fluid pipes in geothermal power generation. While carbon steel pipes are suitable for general fluid conditions, duplex stainless steel NAS64 (UNS S32056) and super duplex stainless steel NAS74 (UNS S32750) is ideal for highly corrosive fluid. There are examples in Japan and overseas, and Nippon Yakin will continue to focus on capturing market share in this application.

Hydrogen stations

Hydrogen is a clean energy source for decarbonisation. The fuel cell vehicle sector is one area in the hydrogen value chain (production, transport, storage and use of hydrogen) that is becoming increasingly practical and commercial.

Hydrogen stations that supply hydrogen to fuel cell vehicles have highly pressurised hydrogen gas environments, posing a high risk of hydrogen embrittlement (brittleness of materials due to exposure to hydrogen). For this reason, a modified type 316L with improved resistance to hydrogen embrittlement is used where normal Type 304 is not applicable.

Demand for heat exchangers manufactured in Nippon Yakin’s modified type 316L is expected to continue to grow for hydrogen stations for hydrogen vehicles. The design won the ISSF 2017 Silver Award for the Best New Applications featuring New Technology; and the Grand Prize of the Japan Stainless Steel Association’s 16th Stainless Steel Association Awards. In addition, high-performance materials such as heat resistant materials, high strength materials and materials for controlling thermal expansion are utilized in various applications in the electrical and electronics industries. Nippon Yakin continues to expand sales of high-performance materials in various areas and industries.

In conclusion

Nippon Yakin aims to continue earning its customers’ trust by providing the industry’s highest levels of quality, delivery, and responsiveness. It is becoming an increasingly sustainable company as it approaches the 100th anniversary of its foundation in 2025 and beyond.

Facts & Figures

Name: Nippon Yakin Kogyo Co. Ltd.

Founded: 1925

Employees: 1,140

Headquarters: Tokyo, Japan

Offices outside Japan: London, Chicago, Singapore, Shanghai, Nanjing

Products: Plates, sheets, coils

Materials: Corrosion resistant stainless steels and alloys, heat resistant stainless steels and alloys, soft magnetic alloys, non-magnetic alloys, high-strength stainless steels, pure nickel, controlled expansion alloys

Website: www.nyk.co.jp/en/

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.