^ piping and valves in the offshore sector

Article By Karan Sotoodeh, Actuators Senior / Lead Engineer, Baker Hughes, Norway

___

Nickel alloys, which are alloys with nickel as the principal element, maybe used for piping as well as different parts of industrial valves such as body, bonnet, ball, seat, stem, bolting, spring, etc.

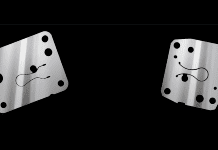

Valves are parts of piping systems and they are defined as components in the fluid flow which are used for different purposes. These purposes may involve stopping / starting the flow, controlling the flow rate, diverting the flow, preventing back flow and releasing the pressure [1] [2]. Figure 1 illustrates a ball valve, which is a rotary valve in which the ball shape closure member is rotated 90° to engage or disengage the port hole of the valve [2]. The ball in figure 1 is engaged to the port hole which keeps the valve open.

Introduction to valves and components

The different parts of the valve mentioned in this paper are defined as follows [3]:

Body:

The valve body – also called the valve shell – is as the most important part of the valve assembly, keeping all the parts together like a framework. The body of the valve is the first pressure boundary receiving the fluid pressure. The valve body ends are designed to connect the valve to the piping.

Bonnet:

Valve bonnet is the second most important pressure containing part; it covers the valve body and is manufactured in the same material as body of the valve.

Ball:

The ball of the valve, also called ‘closure member’ [4] or ‘pressure controlling part ‘[4]stops or starts the fluid. When the valve closes, the full fluid pressure applies to one side of the ball so this part is considered as the third important pressure containing part of the valve [3].

Seat(s):

Seats provide seating surface for the closure member.

Stem:

The valve stem is the connector between the valve closure member and the operator and provides the necessary movement to the ball for closing and opening of the valve. The stem is connected to the hand wheel, lever or actuator from one side and to the valve closure member from the other side. An actuator is a component that is responsible for moving the valve internal automatically. Stems require high mechanical strength, especially in case of actuation, to withstand the loads applyied from the actuator side.

Bolting:

Bolts are also pressure containing parts of the valves, used to connect valve body or bonnet pieces together.

Why specify nickel alloys?

There are various reasons to specify nickel alloys for the valves and the internals. These are summarized as follows:

Internal Corrosion:

In a corrosive environment carbon steel piping maybe clad(overlaid internally) with 3mm nickel alloy (for example Inconel 625) to mitigate the risk of corrosion [5].

The internal overlay of nickel alloy may be implemented for fluid services containing high amounts of corrosive compounds such as CO2 and hydrogen sulphide (H2S). CO2 and H2S corrosion attacks manifest in the form of metal loss and cracks, as illustrated in Figure 3.

Solid nickel alloy, Inconel 625 piping, is also common in the offshore sector of the oil and gas industry in hydrocarbon services with high amounts of H2S.

Consequently, in the parts of the world such as the Middle East where crude oil contains high concentrations of H2S, the valve bodies use in offshore oil and gas projects may be selected in Inconel 625 instead of 22Cr duplex. However, 22Cr duplex is a very common choice for piping and valves in the Norwegian offshore industry where oil and gas are either H2S free or levels are minimal [6]. Additionally, the sealing areas and the seat pockets of ball valves manufactured in carbon steel may be overlaid with Inconel 625 to avoid crevice corrosion. Crevice corrosion refers to a localised attack to the metal surface where there is a gap, crevice or groove.

External corrosion:

Super duplex bolts are a common choice of material for valves manufactured in 22Cr duplex in the Norwegian offshore industry. For example, refer to the piping and valve material specifications of end-users such as Equinor (formerly Statoil) in recent Norwegian projects such as Johan Sverdrup and Johan Castberg.

More information is available at https://www.tr2000.no/TR2000/index.jsp

The maximum allowable operating temperature for uncoated super duplex material (e.g. bolting) in the offshore environment is 110°C [7] to avoid external chloride stress cracking corrosion in the marine environment. Therefore, super duplex bolting (bolts and nuts) are upgraded to Inconel 625 for 22Cr duplex valves in operating temperatures above 110°C as illustrated in Figure 4.

The external grooves such as those located on the Ring Type Joint (RTJ) faces of valve body flanges in carbon steel material are overlaid with Inconel 625 to avoid external crevice corrosion in offshore projects.

Galling and friction:

Galling is a form of wear caused by two surfaces rubbing together. There are various strategies to avoid galling such as lubrication, reducing the roughness and creating a hardness differential between two sliding surfaces. The threaded plug shown in Figure 4 is used to drain the fluid accumulated in the body cavity of the ball valve. The treaded part of the plug creates friction and galling with the body of the valve during opening and closing. Thus, the plug material is chosen in Inconel 625 to create a hardness difference with the body of the valve and consequently reduce galling and friction.

Mechanical strength:

Actuated valves create a high load on the valve stem. Therefore the stem in actuated valves should be manufactured of a high strength material such as Inconel 718 for carbon steel, stainless steel 316 and 22Cr duplex body valves. Inconel 718 may also be used for ball and bolting components, especially in subsea valves.

Cycling and fatigue stress:

A spring is often used in check valves to move the disk back to its original position and close the valve. Many check valves experience a high rate of opening and closing (cycling). For this reason, Inconel X750 spring material is widely specified for check valves due to its good resistance to cycling and fatigue stress. Figure 5 illustrates a dual plate check valve with a carbon steel body and martensitic stainless disks which are closed through the Inconel X750 spring.

Nickel alloy materials

Inconel 625

(Alloy 625) is a nickel-based alloy with high corrosion resistance and mechanical strength. This material has 22% chromium, 9% molybdenum, and around 58% nickel. The strength of this material is derived from the stiffening effect of Molybdenum and Niobium on its nickel-chromium matrix. Relatively high Molybdenum content.

Inconel 718

is a high-strength, relatively highly corrosion resistant, nickel-chromium alloy. This material has approximately 52.5% nickel, 20% chromium and 3% molybdenum.

Fabrication and welding of this alloy are easy, and it has good resistance to fatigue. Two common heat treatments for this alloy are solution annealing and age hardening.

Inconel X750

is another nickel-chromium alloy with high corrosion resistance and high strength. This alloy contains at least 70% nickel and on average 15% chromium. Different mechanical properties may be achieved through different heat treatments for this alloy. This alloy is an economical choice widely used in various industries in addition to oil and gas, such as gas turbines and rocket engines.

Conclusion and recommendation

Inconel alloys such as Inconel 625, 718 and X750 are widely for piping and valves in the offshore sector. The body, bonnet, seat, ball, bolt, plug and spring of ball valves are frequently manufactured from the alloys mentioned. Although nickel alloys are used widely for both internal and external corrosion resistance, they have different applications such as increasing mechanical strength, reducing friction and galling, facilitating cycling and mitigating fatigue stress.

References

- NESBITT B. (2007). Handbook of Valves and Actuators (1st ed.). New York, USA: Elsevier

- SMITH P. & ZAPPE R.W. (2004). Valve Selection Handbook (5th ed.). New York, USA: Elsevier

- EXPLORE THE WORLD OF PIPING (2019). Introduction to Valves-Only the Basics. [Online].

- American Petroleum Institute (API). (2014). Specification for pipeline and piping valves. API 6D. 24th edition. Washington, DC: API.

- BAN S., SHIN Y., LEE S., LEE H. Corrosion Resistance of Inconel 625 Overlay Welded Inside Pipes as a Function of Heat Treatment Temperature. Internal Journal of Electrochemical Science. 11 (2016) 7764-7774, doi: 10.20964.

- SOTOODEH K. Piping and Valve Materials for Offshore Use-Part 1. Stainless Steel World Magazine. 28(2016) 40-44.

- NORSOK M-001, (2014). Material Selection. 5th edition, Lysaker, Norway.

About the author