Voith has launched the world’s largest kraftline machine for SCA. It is expected to significantly increase the latter’s production capacity. Not only is this machine special in its size; it is also made with sustainability in mind.

By Alexandra Kist, Stainless Steel World

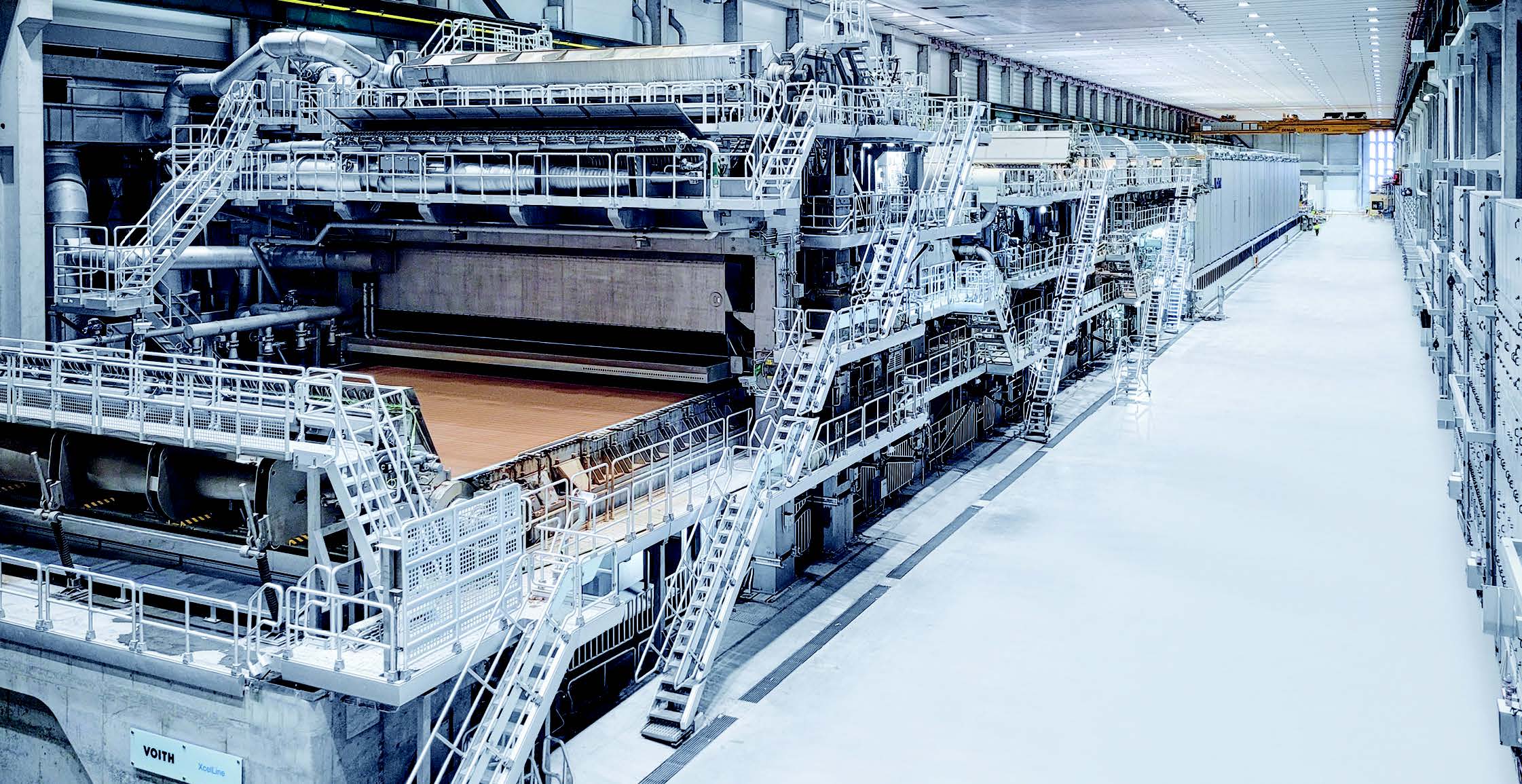

At the beginning of November, Voith successfully started up the world’s largest kraftliner machine for SCA, the Swedish forest industry company, at its Obbola site. The machine features a design speed of 1,400 meters per minute and a wire width of 10,200 mm. The Voith XcelLine paper machine will produce 725,000 tons of high-quality kraftliner per year with basis weights between 100 and 200 gsm. Compared to the old line, the new machine increases SCA’s production capacity by 270,000 tons.

“Thanks to the excellent cooperation with Voith, the start-up of the most modern kraftliner machine took place ahead of schedule,” says Per Strand, Project Director at SCA. “The highly efficient solutions reduce our resource consumption and enable maximum productivity with the lowest overall production costs.”

Voith supplied the complete line, the heart of which is a highly efficient XcelLine paper machine. In addition, they are responsible for all relevant auxiliary systems, from hall ventilation to roll transport, and together with Meri for an efficient water and wastewater management system. The XcelLine paper machine will be supplemented by a new BlueLine stock preparation system, which is scheduled to replace the existing system next year. Voith has supported the SCA team throughout the start-up with a comprehensive training programme.

Stainless steel and corrosion-resistant alloys in the paper industry

The overview below is not a complete one. Instead, we have used examples from the Nickel Institute to give a general summary of most commonly used stainless steels and alloys.

Stainless steels and nickel-containing alloys have a long and successful history in the pulp and paper industry, finding applications in all aspects of the industry. Austhenitic stainless steel and, most recently, duplex stainless steels are used in digesters. Those are typically used in batch cooking, which is a type of chemical pulping process. For oxygen delignification, standard and lean duplex grades are used. The sulphite process entails the production of chemical pulp, and in this endeavour, type 316L stainless steel has become the principal material of construction for sulphite mills, although more highly-alloyed materials are required in a number of specific applications. Duplex stainless steels have been specified, due to their excellent resistance to pitting corrosion and stress corrosion cracking, by chloride ion. There are also several applications where specialty alloys, such as Alloy 20, 6Mo alloys, G30 and C276 (UNS N10276) prove advantageous. When it comes to suction rolls, which are used to remove water from paper at the wet end of the paper machine, the following materials are used: nickel aluminium bronze, forged Type 410 (UNS S41000) along with centrifugally cast stainless steels Type CA15 (UNS J91150), CF3M and CF8M (UNS J92900).

Source: The Nickel Institute

Strong focus on sustainability

For the production of paper, SCA obtains the fresh fibre portion from its own forest stands. In total, SCA’s forest area is 2.6 million hectares – enough to capture 10.5 percent of Sweden’s total carbon dioxide emissions each year. In addition, the new OCC plant has a special focus on sustainable production. The BlueLine stock preparation plant will save up to 40 kWh per ton produced compared to conventional plants. Furthermore, the freshwater requirement is around 30 percent lower than the previous production. Upon completion of the project, SCA will take a big step towards a fossil free industrial process.

Spare and wear parts package and Papermaking 4.0 solutions

With their goal of high production line availability, SCA also ordered a spare and wear parts package from Voith and its subsidiary Meri.

Intelligent automation and digitalisation solutions also create a more sustainable process. As the most modern kraftliner machine in the world, a range of applications from the Voith Papermaking 4.0 portfolio are used along the entire paper machine. These include solutions from the OnEfficiency family that significantly increase line efficiency and stabilise product and process quality. SCA also uses applications from the OnCare family to monitor productivity and enable optimisation measures to be taken quickly. Machine availability is also increased by digital services such as the OnCall.Video remote maintenance service. The digital portfolio is integrated on the Voith IIoT platform dataPARC cloud.

“We are very proud to have successfully set up this major project with SCA,” sums up Dr. Michael Trefz, President Projects at Voith Paper. “PM 2 shows how the latest technologies in combination with innovative automation and digitalisation solutions can lead to significant efficiency advantages.”

References

Pulp & paper. The Nickel Industry website.

About SCA

SCA is Europe’s largest private forest owner. Around this unique resource, SCA has built a well-developed value chain based on renewable raw material from its own and others’ forests. SCA offers packaging paper, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. In 2021, the forest products company SCA had approximately 4,000 employees. SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden.

About Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith is specialised in the markets of energy, paper, raw materials and transport, and automotive. Founded in 1867, the company today has around 20,000 employees, and locations in over 60 countries worldwide.