What is stress corrosion cracking?

Stress corrosion cracking (SCC) is a phenomenon where the combination of tensile stress and a corrosive environment leads to the formation of cracks in a material. It typically occurs in metals and alloys and can weaken structural integrity. SCC is often found in industries such as oil and gas, chemical processing and nuclear power. The cracking process is influenced by factors such as material composition, applied stress levels, and the specific corrosive environment present.

News on stress corrosion cracking

Below you can find a selection of news and articles related to stress corrosion cracking in stainless steels. If you wish to contribute with your case study on stress corrosion cracking, please contact the Stainless Steel World editor

Alleima has secured a prestigious order valued at more than EUR 2.5M from Mayr & Wilhelm for duplex SAF™ 2205 stainless steel heat exchanger tubing.

Denise Caspar joined Mannesmann Stainless Tubes (MST) in April 2023, Stainless Steel World was keen to hear her take on trends in this flourishing sector.

Stainless steel is popular compared to other metals, its valuable characteristics, resistance to different kinds of liquid, chemical and gaseous corrosion.

This article discusses procurement and construction challenges and the best practices developed to overcome these challenges.

Stamicarbon, the innovation and license company of MAIRE Group, has signed a contract covering PDP, licensing and equipment supply for an Ultra-Low Energy grassroots...

Stamicarbon, the innovation and license company of MAIRE Group, has signed a contract covering PDP, licensing and equipment supply for an Ultra-Low Energy grassroots...

Stainless steel is popular compared to other metals, its valuable characteristics, resistance to different kinds of liquid, chemical and gaseous corrosion.

Hydrogen plays an important role in the energy transition. However, to achieve the 2030 climate targets, a significant jump in scale is required in...

Sverdrup and Fabtech have used lean duplex to create a footbridge, to save on lifecycle cost, maintenance, and overall weight

Offshore oil and gas platform and floating vessel owners must optimize costs. But moreimportantly, they must maintain safe and compliant operating conditions for employees overthe life span of their operations.

The dangers of SCC

Stress corrosion cracking (SCC) is a complex and potentially catastrophic phenomenon that occurs when a combination of tensile stress, a corrosive environment, and a susceptible material interact. Unlike traditional corrosion, which is a gradual and uniform degradation of a material, stress corrosion cracking involves the formation and propagation of cracks, often leading to sudden failure.

Stress corrosion cracking commonly affects metals and alloys, such as stainless steels, aluminum alloys, and nickel-based alloys. It can occur in various industries, including oil and gas, chemical processing, aerospace, marine, and nuclear power.

The specific mechanisms behind stress corrosion cracking are complex but certain conditions are known to promote its occurrence. These include the presence of a corrosive environment (e.g., chloride ions in aqueous solutions), applied tensile stress, and material susceptibility. The combination of these factors leads to crack initiation, propagation, and eventual failure.

Cracks associated with stress corrosion failure can develop in different patterns, such as intergranular, transgranular, or a combination of both. The cracks may follow grain boundaries or propagate through the grains of the material. Stress corrosion is often difficult to detect because it can occur internally, hidden from visual inspection.

Can you prevent stress corrosion cracking?

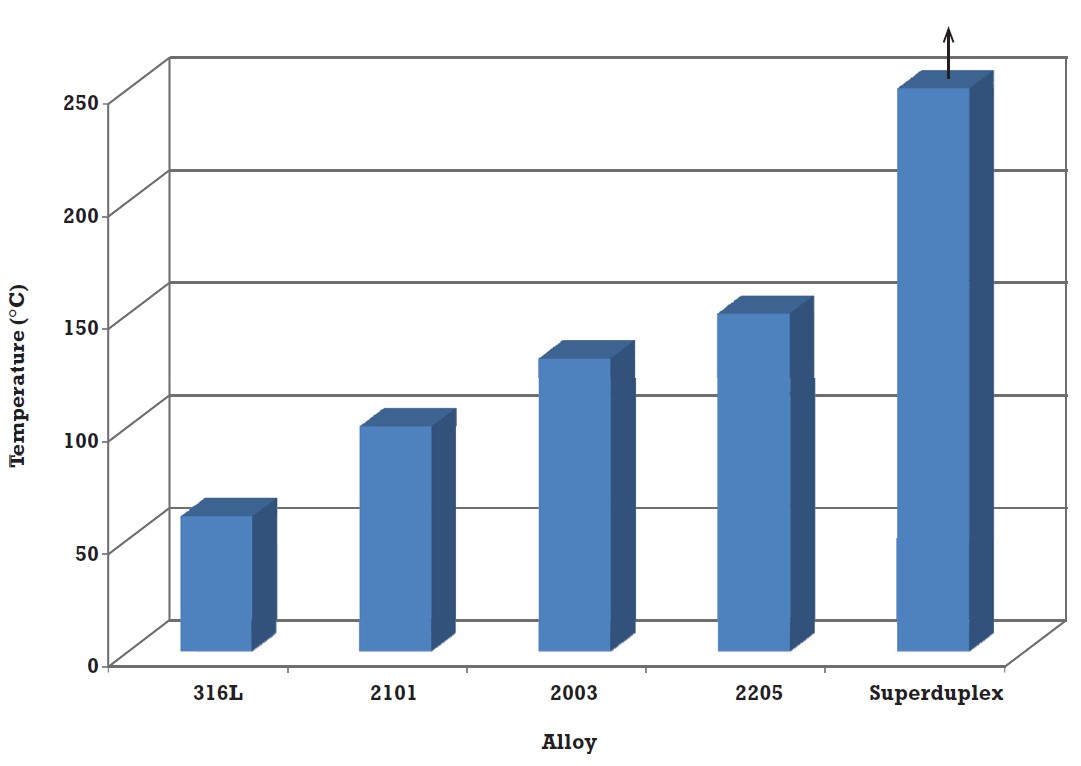

Preventing stress corrosion cracking involves understanding and controlling the factors that contribute to its initiation. Strategies include material selection, minimizing tensile stress levels, applying protective coatings, utilizing corrosion inhibitors, and maintaining appropriate environmental conditions. Regular inspections, non-destructive testing, and monitoring are crucial to identifying early signs of stress corrosion cracking and preventing catastrophic failures.