AvestaPolarit has upgraded the gas control system on its argon oxygen decarburisation (AOD) convertor at its steel mill on Shepcote Lane in Sheffield. This will provide greater operational flexibility through increased gas flows and enhanced control capability during the refining of stainless steel. AvestaPolarit is the largest stainless-steel maker in the UK and is a subsidiary of Outokumpu of Finland. AvestaPolarit in Sheffield manufactures a wide variety of steel grades, finishes and products that are supplied to a broad group of customers who, in turn, make anything from cutlery to industrial chemical plants. The site at Shepcote Lane has a melting plant with a capacity of over 500kt of finished products each year, along with cold rolling and finishing facilities that produce around 300kt of finished product annually.

Production at the site consists of stainless sheet between 0.4 and 6mm in thickness and up to 1.5m wide. The AOD convertor is used to remove carbon to the extremely low levels required for stainless steels with the liquid steel being supplied from the electric arc furnace (EAF) at the plant. The gas system is designed for continuous operation, 24 hours per day, seven days a week and was supplied by VAI Industries (UK) to give increased gas flows and better control.

The four main gases are oxygen, pure and industrial argon and nitrogen, which are blown into the steel at high pressure through submerged pipes at the bottom of the AOD convertor.

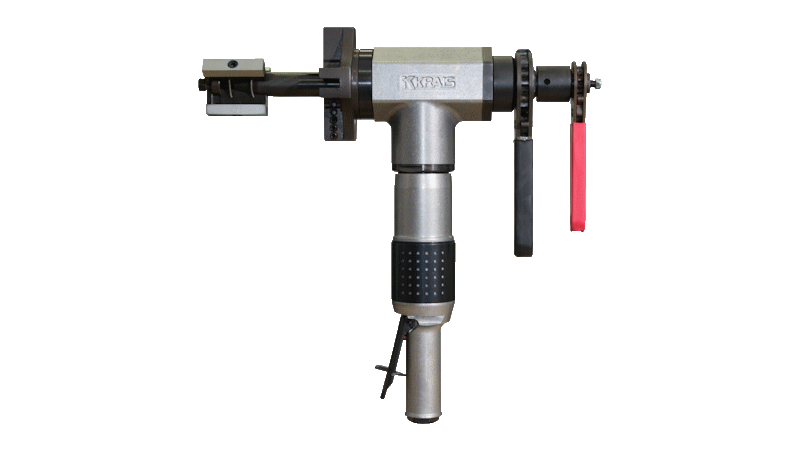

AvestaPolarit stipulated that all control valves were to be pneumatically actuated, controlled with electropneumatic positioners with closed position indication. The block and vent valves were also pneumatically operated fitted with open and closed position indication switch boxes. Flowserve Flow Control, already an approved supplier to AvestaPolarit, was chosen to provide valves for the system. Nine Worcester V-Flow control valves were stipulated (including four in stainless steel and four in Monel) to deal with the highly demanding application. Additionally, Worcester Controls’ manual isolation valves, ranging up to 150mm including three Series 52 valves in Monel were incorporated into the system. All pneumatically operated valves were fitted with Norbro actuators and PMV/Norbro ancillaries.