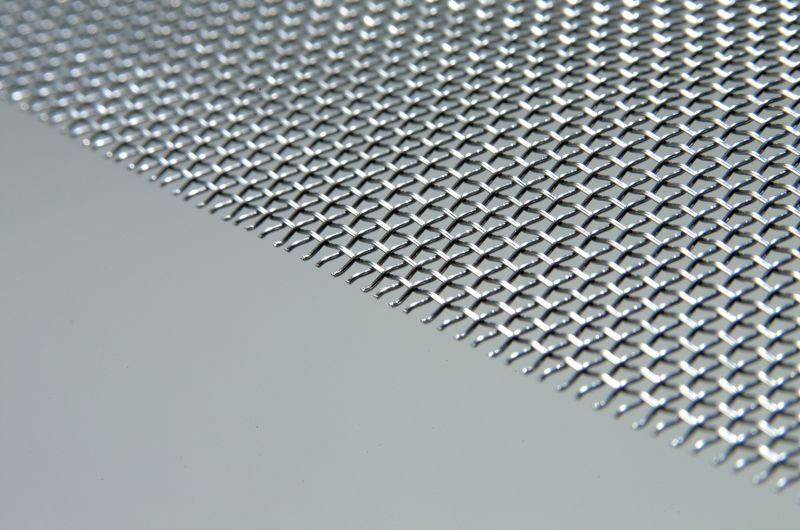

While screens can be manufactured with different mesh counts and wire diameters, they can also be woven with different materials.

Type 304 and Type 316 stainless steel are by far the most common materials of construction for screens used in the processing of granular and powder materials. These materials exhibit a desirable combination of availability, economy, durability, and corrosion resistance.

Some meshes are available in Type 430 stainless steel which, unlike most stainless steels, can often be picked up by magnets that are placed downstream of the screening machine. Since screens inevitably break over time, this improves the odds of capturing stray wires that might become detached from the screen. However, screens woven from Type 430 stainless steel tend to be more brittle and therefore can exhibit shorter service lives.

Screens can also be woven of synthetic materials like polyester or nylon. These are chosen when even materials such as stainless steel could not withstand the corrosive action of the material being screened.