The newly introduced super duplex grade, SAF™ 3006, incorporates the benefits of SAF™ 2507 and other duplex grades while also offering excellent corrosion resistance in acidic and caustic environments. Its general corrosion resistance, combined with very high resistance to chloride-bearing environments, make it ideal material for the chemical and petrochemical process industry.

By Oscar Öhlin, Senior R&D Engineer, Tube R&D, Alleima Tube AB, Sweden & Angela Philipp, Technical Marketing Specialist, BU Tube EMEA, Alleima, Germany

Duplex stainless steels are a family of stainless steels that combine the beneficial properties of both austenitic and ferritic stainless steels. They are characterized by a two-phase microstructure consisting of approximately equal amounts of austenite and ferrite. This unique combination results in a material that offers excellent mechanical properties and corrosion resistance compared to standard austenitic or ferritic stainless steels.

The dual-phase structure of duplex stainless steels provides high strength and toughness, making them suitable for demanding applications in various industries, including oil and gas, chemical processing, and marine environments. Additionally, duplex stainless steels exhibit excellent resistance to stress corrosion cracking, pitting, and crevice corrosion, which are common issues in aggressive environments.

Due to their enhanced performance characteristics, duplex stainless steels are increasingly being used as a cost-effective alternative to traditional stainless steels and other corrosion-resistant alloys. Their ability to withstand harsh conditions while maintaining structural integrity makes them an ideal choice for critical applications where reliability and longevity are of importance.

Alleima’s contribution to the duplex development

Alleima has been one of the leading companies in the duplex development since the 1960s, where the first duplex grade was introduced, Alleima® 3RE60 (UNS S31500). This lean duplex grade was specifically developed to improve resistance to stress corrosion cracking (SCC), addressing the issues faced by standard austenitic steels such as AISI 304L and AISI 316L in chloride-rich environments.

In the 1970s, advancements in the Argon Oxygen Decarburization (AOD) process enabled more efficient decarburization and higher precision in nitrogen alloying. This led to the development and market introduction of SAF™ 2205 (UNS S32205), which set a new standard as the “workhorse” of duplex stainless steels. During the 1980s, the super duplex grade SAF™ 2507 (UNS S32750) was introduced.

With a Pitting Resistance Equivalent (PRE) above 40, this grade offered excellent resistance to chloride-induced localized corrosion such as pitting and crevice corrosion. Originally developed for demanding applications, SAF™ 2507 has found extensive use in marine environments and heat exchanger applications.

In the 2000s, Alleima developed the hyper duplex grades SAF™ 2707 HD (UNS S32707) and SAF™ 3207 HD (UNS S33207), pushing PRE values close to 50. These hyper duplex grades were created to meet market demand for improved pitting corrosion resistance. They offer the highest pitting corrosion resistance and strength among modern duplex stainless steels, setting a new industry standard.

In 2024, Alleima launched two new super duplex grades, SAF™ 3006 (UNS S83071) and SAF™ 3007 (UNS S83072). SAF™ 3006 is tailored for heat exchanger applications facing general corrosion challenges in acidic and caustic environments, while SAF™ 3007 has been developed specifi cally for subsea umbilicals.

Super duplex SAF™ 2507

SAF™ 2507 (UNS S32750) is a high alloy super-duplex stainless steel designed for service in extremely corrosive conditions. It is developed for demanding applications that require high mechanical strength and where the material is subjected to high stresses in chloride-containing environments, such as seawater. The minimum Pitting Resistance Equivalent (PRE) value for SAF™ 2507 seamless tubes is 42.5. This value is significantly higher than the PRE values for other 25Cr type duplex stainless steels, which are not super duplex. The PRE value is equal in both the austenite and ferrite phases of SAF™ 2507, achieved through a careful balance of alloying elements. This balance ensures superior resistance to pitting corrosion, making SAF™ 2507 an ideal choice for chloride containing environments. SAF™ 2507 is included in numerous product standards and is also part of the ASME pressure vessel code.

The new super duplex SAF™ 3006

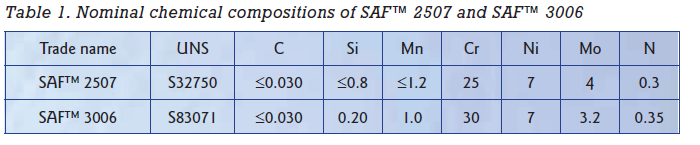

SAF™ 3006 (UNS S83071) is a high-alloy super duplex stainless steel designed for general corrosion resistance in acidic and caustic environments. Unlike most other duplex grades, which are developed to maximize chloride resistance and Pitting Resistance Equivalent (PRE), SAF™ 3006 is optimized for general corrosion resistance. This optimization provides SAF™ 3006 with advantages in applications where traditional super duplex grades experience high corrosion rates due to general corrosion. The composition of SAF™ 3006 is carefully balanced to ensure high structural stability and excellent weldability. The nominal composition of SAF™ 3006 is shown in Table 1. SAF™ 3006 is included in product standards for tube and pipe, specifically ASTM A789 and A790. It also has pressure vessel approval per ASME Section VIII Code Case 2914.

A comparative analysis of SAF™ 3006 and SAF™ 2507

Mechanical strength

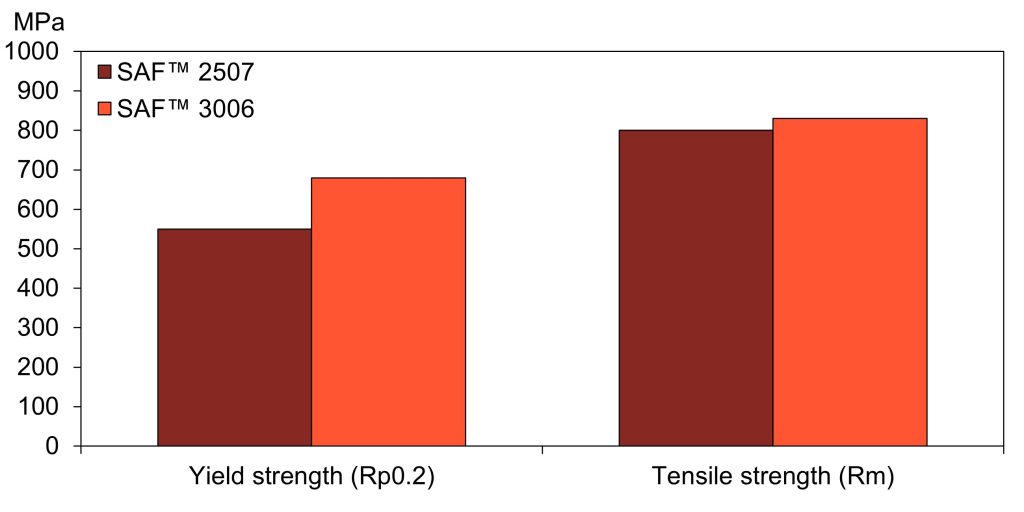

One of the key benefits of duplex stainless steel is its mechanical strength. The higher strength often allows for substantial reductions in material thickness, which lowers the weight and total cost of installations. The mechanical strength of SAF™ 3006 is particularly high, with both yield strength and tensile strength exceeding those of SAF™ 2507. This provides significant design and cost advantages. The requirements for SAF™ 3006 and SAF™ 2507 can be seen in Figure 1, which presents the yield strength (Rp0.2) and tensile strength (Rm) of the grades.

General corrosion

In many applications, corrosion occurs as a uniform attack over the surface of the material when exposed to a corrosive medium, also known as general corrosion. The most common environments where general corrosion occurs are in aggressive acid or caustic solutions, where the specific composition of the environment is crucial for the corrosiveness.

Alleima’s duplex stainless steel grades offer specific benefits across a wide range of conditions, environments, and media found in the process industries. The resistance of duplex stainless steels to general corrosion is a key factor in prolonging the service life of process equipment.

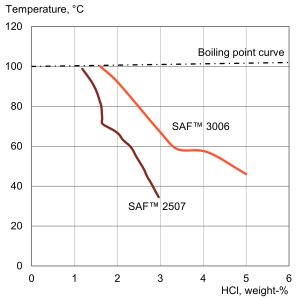

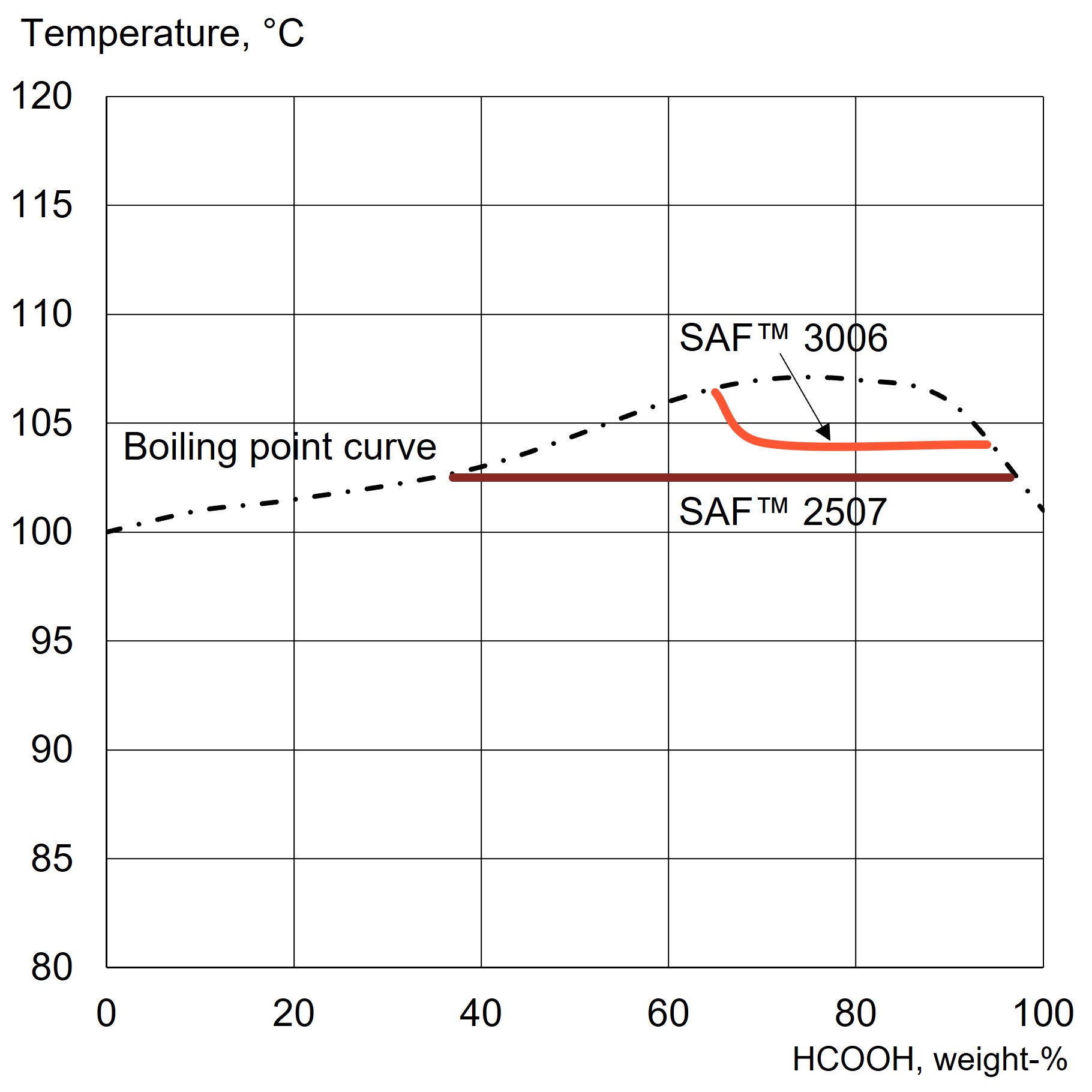

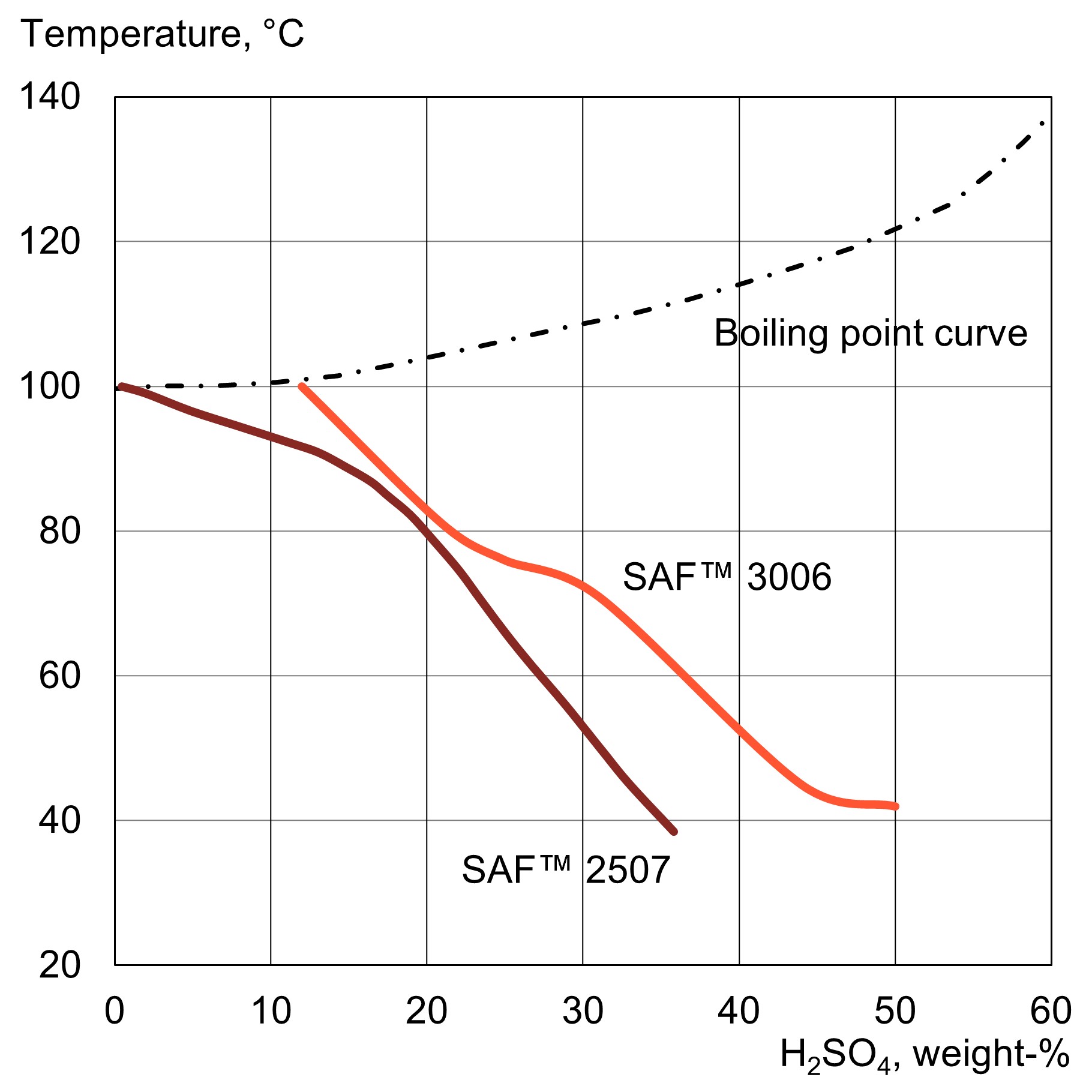

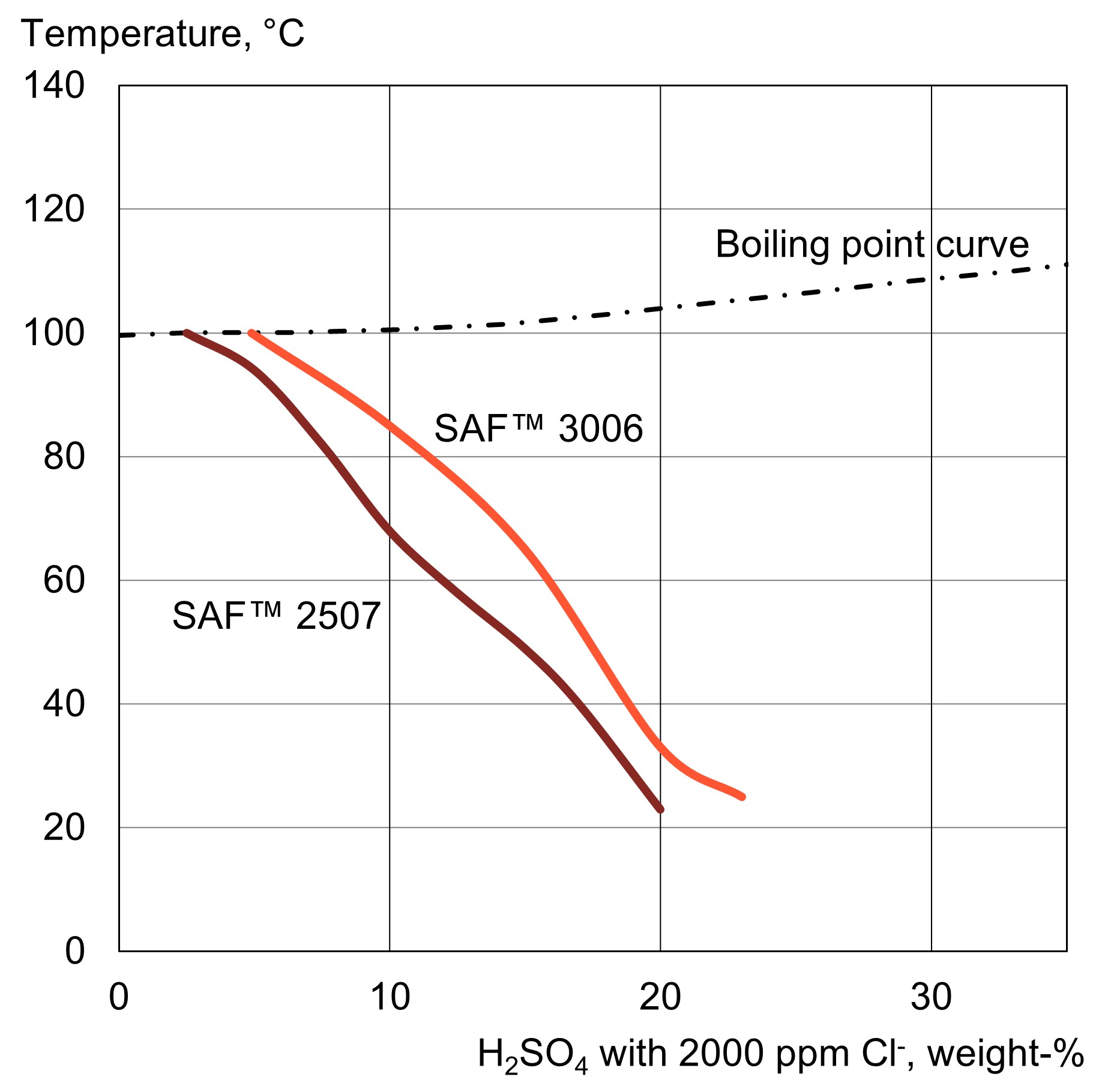

Figures 2 to 5 show the iso-corrosion diagrams of SAF™ 3006 and SAF™ 2507 in hydrochloric acid (HCl), sulfuric acid (H2SO4), sulfuric acid with the addition of 2000 ppm chlorides, and formic acid (HCOOH). The curves in the iso-corrosion diagrams represent a corrosion rate of 0.1 mm/year. This means that above the curve, the corrosion rate is higher, and below it, the rate is lower than 0.1 mm/year.

Both SAF™ 3006 and SAF™ 2507 exhibit very high resistance to general corrosion in acidic environments. However, the resistance of SAF™ 3006 is higher than that of SAF™ 2507.

Localized and crevice corrosion

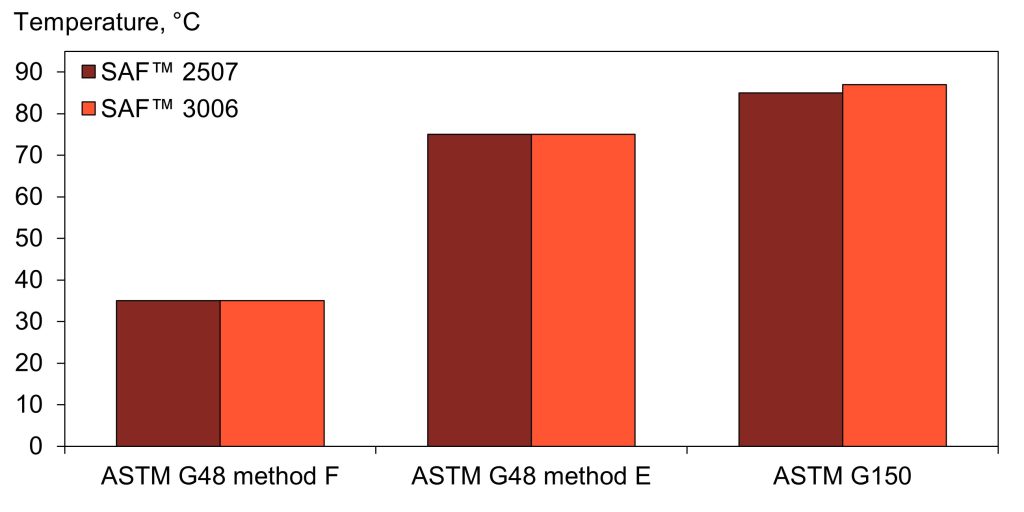

The resistance to pitting and crevice corrosion is primarily determined by the content of chromium, molybdenum, and nitrogen in the material. Both SAF™ 2507 and SAF™ 3006 have carefully balanced compositions with high contents of these elements, which provide these grades with excellent resistance to localized corrosion induced by chlorides.

To evaluate this resistance, laboratory test methods such as ASTM G48 Method E and ASTM G150 are used to determine the Critical Pitting Temperature (CPT), while ASTM G48 Method F is employed to determine the Critical Crevice Temperature (CCT). The CPT and CCT are the temperatures at which pitting or crevice corrosion begins to develop on the material. In Figure 6, the CPT and CCT of SAF™ 2507 and SAF™ 3006 is presented. SAF™ 3006 exhibits pitting and crevice corrosion resistance comparable to that of SAF™ 2507, which has an established track record of performance in seawater applications.

Stress corrosion cracking resistance

SAF™ 2507 and SAF™ 3006 have excellent stress corrosion cracking resistance. Duplex stainless steels are far less prone to this type of corrosion compared to austenitic stainless steels. Practical experience and laboratory tests have shown their good resistance to stress corrosion cracking.

SAF™ 3006 – the ideal choice

For over two decades, SAF™ 2507 has been the super duplex material of choice for applications in the chemical and petrochemical industry. The newly introduced super duplex grade, SAF™ 3006, not only incorporates all the benefits of SAF™ 2507 and other duplex grades but also offers excellent corrosion resistance in acidic and caustic environments. Its excellent general corrosion resistance, combined with very high resistance to chloride-bearing environments, positions SAF™ 3006 as an ideal material for the chemical and petrochemical process industry.

When super duplex and austenitic grades encounter challenges with general corrosion, SAF™ 3006 provides a robust solution, offering the necessary safety margin to prevent rapid corrosion of equipment. Additionally, the excellent performance of SAF™ 3006 contributes to extended service life and reduced maintenance requirements in various types of heat exchangers. These features, combined with its very high mechanical strength, make SAF™ 3006 a cost-effective alternative to austenitic stainless steels and nickel-based alloys.

About this Tech Article

Appearing in the February 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.