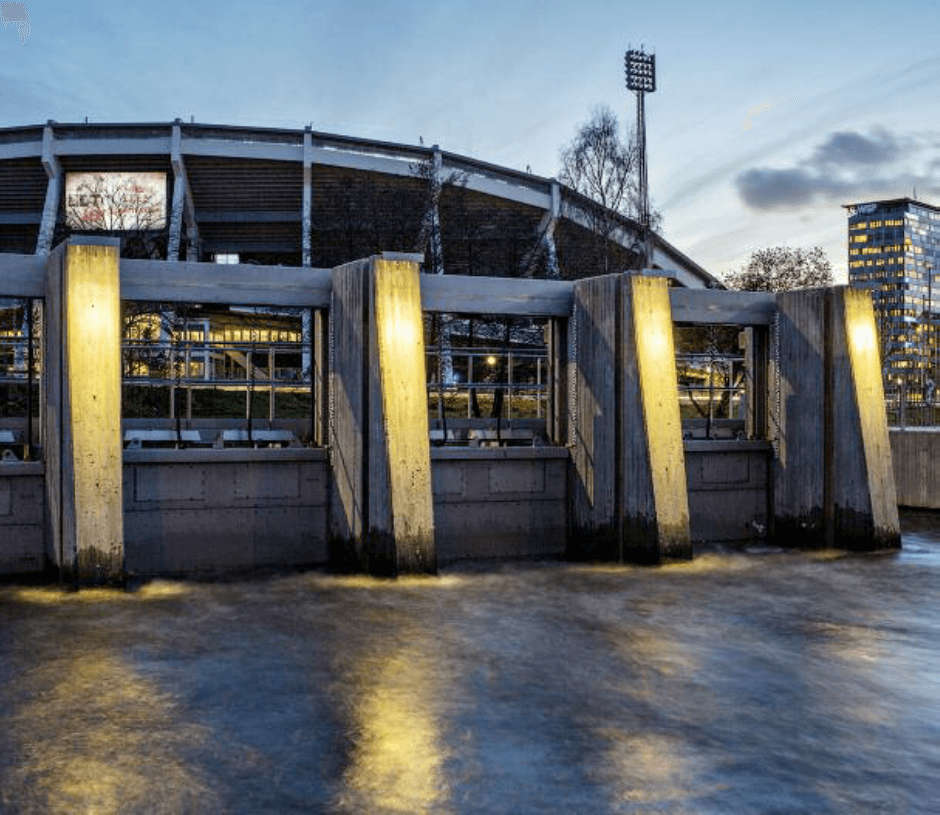

Flood prevention gates at Mont St Michel France. Photo: Dreamstime

Sluice gates are movable barriers that regulate water levels and flow rates in waterways. In a world of changing climate and increased flooding risks, these gates need to be taller and stronger than ever before. Thanks to their strength and corrosion resistance, molybdenum-containing duplex stainless steels are the ideal construction material.

By Karlee Williston, IMOA

Traditionally made of wood or metal, sluice gates make life possible in the world’s most populous places: along rivers or coastal regions, which are often vulnerable to flooding. The basic technology behind sluice gates is ancient – Sri Lankan society used them over 4000 years ago – but their refinement continues today. Some modern sluice gates use duplex stainless steel, which offers substantial benefits over other construction materials. The projects detailed below showcase how these gates conserve material, capital, and emissions throughout their service lives.

Mont St-Michel, Avranches

Mont St-Michel is a tidal island with an abbey that appears to float on the ocean. The granite rock lies about 1km off the north-western coast of France, near Avranches. Since the 8th century, religious pilgrims crossed the muddy sands, revealed only at low tides, to reach the abbey. But the everchanging display of water and light around the monastery was under threat. A steady flow of silt from the Couesnon, Sée, and Selune rivers and sand, brought into the bay by high tides, accumulated between the rock and the coast, continuously joining Mont St-Michel with the land. The reasons for this build-up of silt and sand go back to the 19th century, when the rivers were diverted to create pasture land, preventing them from properly carrying the deposits into the sea. To make things worse, a dike built in 1869 to provide visitors with a permanent connection to the island, further impeded free drainage. Now the sands at the foot of Mont St-Michel are 3m higher than they were 200 years ago. To reduce this deposit build-up, the French government had a dam built on the Couesnon river. Eight sets of sluice gates, clad with 2205 duplex stainless steel, retain the river water at high tide and release it at low tide, allowing it to flush sediment out to sea. Additionally, the old dike that blocked water flow was replaced by a

Mont St-Michel is a tidal island with an abbey that appears to float on the ocean. The granite rock lies about 1km off the north-western coast of France, near Avranches. Since the 8th century, religious pilgrims crossed the muddy sands, revealed only at low tides, to reach the abbey. But the everchanging display of water and light around the monastery was under threat. A steady flow of silt from the Couesnon, Sée, and Selune rivers and sand, brought into the bay by high tides, accumulated between the rock and the coast, continuously joining Mont St-Michel with the land. The reasons for this build-up of silt and sand go back to the 19th century, when the rivers were diverted to create pasture land, preventing them from properly carrying the deposits into the sea. To make things worse, a dike built in 1869 to provide visitors with a permanent connection to the island, further impeded free drainage. Now the sands at the foot of Mont St-Michel are 3m higher than they were 200 years ago. To reduce this deposit build-up, the French government had a dam built on the Couesnon river. Eight sets of sluice gates, clad with 2205 duplex stainless steel, retain the river water at high tide and release it at low tide, allowing it to flush sediment out to sea. Additionally, the old dike that blocked water flow was replaced by a

light bridge on stilts. The bridge allows the free flow of water around the island, improving the efficiency of deposit removal from the bay.

Some 36 tonnes of duplex stainless steel plate, supplied by Industeel, clad the gates’ coated carbon steel frame. 2205 duplex stainless steel, containing 3% molybdenum, was chosen for its superior corrosion and abrasion resistance. The molybdenum content helps fend off both corrosion from seawater and abrasion from sediments. With lots of abrasive particles and high flow rates, ‘erosion corrosion’ is a significant risk for corrosion-prone, softer materials like aluminium or carbon steel. Wet-dry interfaces, inevitable in a water management system, can also exacerbate corrosion. A carefully welded duplex stainless steel surface, with its high hardness and corrosion resistance, will resist these perils far better than other metals or lesser alloyed grades.

The Couesnon dam, which faces the abbey and the open bay, has become its own tourist attraction. Project architects designed a public space atop the dam, which offers unobstructed views of Mont St-Michel and attracts millions of people to visit this UNESCO World Heritage Site every year.

Slussen, Stockholm

Slussen is a lock right in the middle of the historic city centre of Stockholm, Sweden. It was first built in the 17th century. This lock protects the two million people of Mälardalen, the area around lake Mälaren at the eastern end of Stockholm, and their drinking water from inflows of brackish water. The lock is such a defining feature of the area that the neighbourhood itself is called ‘Slussen.’ The neighbourhood is one of Stockholm’s busiest, and its heavily travelled, water-traversing infrastructure can be difficult to access for maintenance. A massive urban planning project is underway to widen Slussen’s discharge canals, transform its public transportation throughways, and install new sluice gates. The new gates, two for control of water level and two for boat traffic, are designed to withstand brackish flood waters for a century. That is a tough ask of steel, which wants to rust under such conditions. 2205 duplex stainless steel, however, is perfect for the job.

Flooding around lake Mälaren is a major concern due to increased rainfall and warmer winters in recent years. The year 2000 was Sweden’s rainiest since 1860. In that year, significantly more water flowed into lake than could be let out through the sluice gates. The flooding was so bad it almost reached the central underground station tunnel of Stockholm. Nearby, the train station of Gamla Stan (i.e. the Old Town) wasn’t so lucky; water infiltrated its ticketing hall, leading it to close for a brief time. In the two decades that followed, climate modelling confirmed this event was not an anomaly. Rather, similar extreme flooding events are likely to increase in both frequency and intensity. Although Gamla Stan’s train tracks never flooded, the floods of 2000 are perhaps a warning for what is yet to come. Without improved capacity to drain floodwaters from lake Mälaren, the whole Stockholm region would be vulnerable to unprecedented disaster. The new duplex stainless steel sluice gates will be large and strong enough to release significantly more water than their forebears.

Because duplex stainless steel is so much stronger than carbon steel, the gates are light enough to be fabricated off site and delivered. Being able to weld in a fabrication shop versus on site not only conserves costs and resources, but it also allows for better quality control. Stål and Rörmontage fabricated and supplied the behemoth flood gates – now the world’s largest at 70 tonnes. The gates will protect against the surges of storms, which will increase in intensity and frequency throughout the lock’s service life. The entire Slussen project is expected to finish in 2025.

Gårda Damme, Gothenburg

Gothenburg, a Swedish port city, stretches over a series of islands intersected by canals and bridges. With so many waterways, rising sea levels pose a major flood risk to the community. In 2013, the rotten wooden sluice gates that once controlled the water flows

in and out of the archipelago were replaced. The old gates were in such bad condition that a temporary support structure was necessary to hold them together. The new gates are designed to withstand 120 years of rising tides. Though Gothenburg’s canals usually hold fresh water, sea water occasionally backwashes in and increases the chloride content. Outokumpu’s 2404 duplex stainless steel, containing 1.6% molybdenum, was chosen for both its strength and enhanced resistance to salts. The structure could last several times its specified service life if the rubber seals used on the gates are properly maintained. There are five gates altogether, each measuring 3.1 by 2.2m and weighing roughly 7 tonnes. Rotten as they were, the original wood sluice gates were a beautiful landmark in the city, and residents wanted to emulate some of their character. The fabricators pieced together the new gates with over 400 specially crafted components to replicate the wooden aesthetic.

The gate to safer communities

Duplex stainless steel has a longer service life, requiring less maintenance than other materials. Even though duplex stainless steel is more expensive upfront, when the total life cycle costs of a project are considered, it usually emerges as a more cost-effective solution. Not having to repaint, recoat, or replace components on the sluice gates means no chaotic road closures for maintenance, no gaps in flood protection for the city, and less greenhouse gas emissions from producing and moving new materials. Managing the shifting waters of the 21st century will not be easy, but duplex stainless steel will help resist the rising tide.

Corrosivity of brackish waters

Brackish waters vary widely in their corrosivity to metals – some brackish waters are almost like fresh water while others approach the saltiness of the ocean. However, chloride (salt) concentration is only one variable affecting corrosion in brackish water – temperature, bacteria levels, dissolved solids, and pH also play a role in material degradation. 2205 duplex stainless steel is much more corrosion resistant than type 316 stainless steel and can withstand higher levels of chlorides. While less corrosion resistant than 2205, 2404 duplex stainless steel is also more resistant than type 316 and works well in brackish water with lower chloride contents.

About IMOA

Reproduced with the kind permission of the International Molybdenum Association (IMOA). IMOA is a non-profit trade association representing the majority of the molybdenum industry worldwide. For information, visit www.imoa.info

About this Featured Story

This Featured Story appeared in Stainless Steel World April 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE) .

Want to contribute as author? Please contact Joanne.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.