– Tubacex

___

Typical challenges

Typical high temperature problems

- Cracking of the tubes in application

- Reduction of wall thickness of tubes

- Scaling on the surface of the tubes

- Erosion Corrosion of tubes – why does this happen?

- Deposite of solids from the process

- Hot Corrosion Mechanism

- Oxidation

- Carburisation

- Sulphidation

- Nitriding

- Erosion due to solid particles from process

- Low Creep resistance

Tubacex 253 MA

Creep strength

Microstructure stability

Corrosion resistance

Oxidation

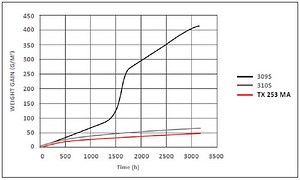

– Tubacex 253 MA has an extraordinary resistance to oxidation. The well-defined composition of chromium, silicon and micro-alloying with REM produces a strong adherent tough complex oxide film of SiO2.Cr2O3. The oxide film of silicon and chromium provides a low diffusion rate for oxygen and metal ions, which retards the oxide growth and thus imparts a high oxidation resistance to the alloy. Micro-alloying assists in anchoring the oxide to the matrix thereby preventing oxide rupture and scaling. All this is particularly beneficial under rapid fluctuations of temperature (cyclic oxidation conditions). As shown in Figure 4, Tubacex 253 MA presents better cyclic oxidation response than 309S and 310S steel grades.

Sulfidation

– Sulfur has a very negative effect on the service life of exposed components. Sulfides (especially lowmelting point Ni-bearing sulfides) can form and attack the underlying metal through cracks or pores present on the protective oxide layer. Tubacex 253 MA is very resistant to sulfur containing atmospheres (superior to AISI 309, 310 and the nickel alloys) mainly due to two reasons:

- Its ability to form a thin, tough and adherent oxide layer, so that sulfur diffusion through the layer is difficult.

- Rare Earth metals can form oxysulfides thus preventing the formation of other harmful sulfides that would attack the underlying metal.

Nitridation

– The risk of using nitrogencontaining atmospheres is that, when nitrogen diffuses into the underlying metal, chromium nitrides can be formed. Chromium nitrides have an embrittling effect and also, due to their high chromium content, produce a chromium depletion in the adjacent areas that impairs the corrosion resistance of the material. To avoid this, a dense protective oxide layer is needed.

Ni content is also important as this element doesn’t react to form nitrides. Provided that traces of oxygen are present, Tubacex 253 MA has very good nitriding resistance (better than AISI 309 and 310) due to the nature of its protective layer (thin, tough and adherent). In atmospheres with no or very little oxygen, such as cracked ammonia gas, grades with higher nickel (AISI 314, 310, Alloy 800H) show superior resistance.

Carburization

– To prevent carburization, which produces embrittlement and damages the corrosion resistance of stainless steels, the most effective protection is a solid oxide layer. Tubacex 253 MA, with REM and silicon additions, develops an improved scale (thin, tough and adherent) that makes this grade highly resistant to carburization compared with other grades such as AISI 310 and Alloy 800H.

When the atmosphere is alternately oxidizing and carburizing, the protective scale tends to grow with exposure time and it may break. In such a case, carburization can progress through the damaged oxide layer. Under these conditions, Tubacex 253 MA is less resistant than grades with higher chromium and nickel (AISI 314, 310, Alloy 800H).

Potential applications

- Air preheater tubes in carbon black industry.

- Recuperator tubes in metallurgical industries.

- Heat treatment furnaces tubes, furnace rollers.

- Thermocouple protection tubes, oxygen probes.

- Soot blower tubes in power generation.

- Lance tubes for lime kilns.

- Lancing tubes for pulverized coal injection in blast furnace.

- Flare tip in refinery.

- Ketene furnace tubes.

- Tubes for the glass and cement industries