Outokumpu’s mill in Tornio, Finland, where Circle Green sustainable stainless steel is produced.

Outokumpu is pioneering the production of emission-minimised stainless steel in the global market. Its Circle Green product line has an astonishing 92% lower carbon footprint than the global average, and the company now provides product specific carbon footprint data for many of its products. Stainless Steel World spoke to Max Menzel, Head of Sustainability & Technical Customer Service, to learn how Outokumpu is shaping the stainless steel market for a cleaner future.

By Joanne McIntyre

Max began by highlighting that Outokoumpu is currently the only stainless steel producer that is SBTi (Science Based Target initiative) approved, which is an outstanding benchmark to achieve. With a clearly stated ambition of reducing its carbon footprint from the baseline of 2016 to 2030 by 42%, the company is well on track. Its sustainable stainless steel production has the lowest average carbon footprint available.

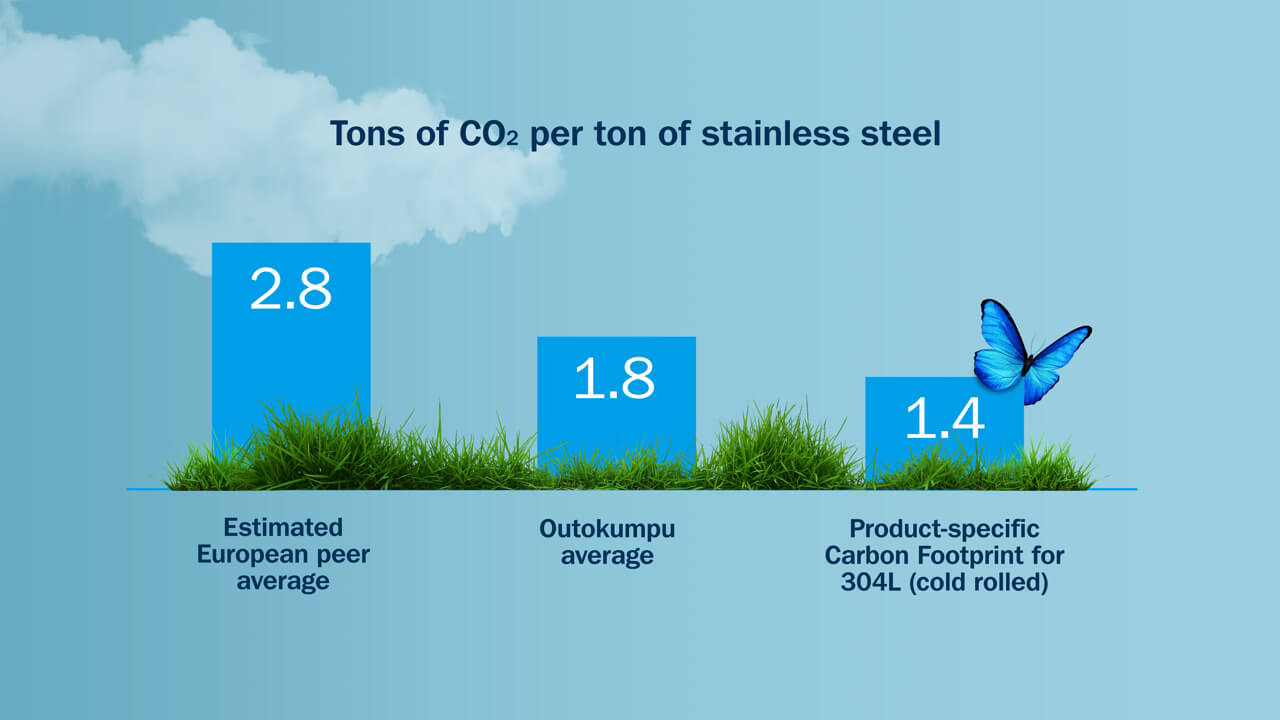

“Outokumpu has achieved the lowest carbon footprint in the industry, 70% lower than the global average, while the Circle Green line is up to 92 % lower. Our carbon footprint is approx. 1.8 tons of CO2 per ton of stainless steel produced.” Sustainability has been an important focus for the company for many years.

Significantly, Outokumpu promotes full transparency in the industry to achieve these goals. This means covering all Scope 1, 2 and 3 emissions when reporting emissions and a commitment to provide this detailed information for every product.

“We’re the only European stainless steel producer to provide full transparency on all three scopes to the outside world,” explains Max.

“We believe this is essential to fully decarbonise and transform the industry. Our long-term climate target is to reduce our direct and indirect CO2 emissions and those of our supply chain (Scopes 1, 2 and 3) by 2030 and reach carbon neutrality by 2050.”

Milestones to achieving emission reduction

Very high utilisation of recycled materials is one of the key factors in lowering CO2 emissions. Outokumpu achieved 94% recycled content in its stainless steel in 2022; an excellent result highlighting the company’s focus on the circular economy. It currently recycles over two million tonnes of stainless steel per year.

Outokumpu is unique in that it is the only major stainless steel producer with its own chromium mine and ferrochrome production, both of which are equipped with the latest technology.

“Our ferrochrome raw material has a very low carbon footprint 42 % lower than industry average of the industry average,” continues Max.

“Furthermore, we aim to achieve carbon neutrality at our Kemi chrome mine by 2025, which would be truly unique in the world. Having this key raw material available is a huge benefit for our sustainability goals.”

Product specific carbon footprint

Outokumpu is the first stainless steel producer to provide a product-specific carbon footprint on its stainless steel products based on continuous production data. This helps customers achieve emission-reduction goals and supports Outokumpu’s long-term climate targets and sustainability strategy.

“There has been great resonance in the market to this,” explains Max. “Customers are paying more attention to cutting down emissions, asking for specific information about the carbon footprint of each product. We’re happy to be the first stainless steel producer to provide the information for products produced in our European mills. Customers can utilise the data to calculate the carbon footprints of their products and provide more sustainable solutions to the market. The CO2 value is averaged over 12 months, but is updated every month. For example, if we improve our energy efficiency, customers will immediately see that reflected in the product specific carbon footprint.” Max explains further: “We enable our customers to move from CO2 reporting to active CO2 management. You can manage your Scope 3 emissions and your company’s carbon footprint by using our products which offer full transparency. We’re playing a leading role in driving ahead change by delivering clear facts to the market.”

Transparency from suppliers

Outokumpu includes Scope 1, 2 and 3 emissions in its product specific carbon footprint calculations. Scope 3 covers the raw materials and is challenging to assess in a global market where not every supplier can provide carbon footprint data.

“We have a team in our raw material procurement department dedicated to assessing the sustainability of our raw material suppliers. They visit for example the mines of our suppliers to determine the business procedures and also assess the ESG (Environmental Social Governance) goals.”

This is yet another way Outokumpu is pushing the industry forward, encouraging all parties in the supply chain to operate transparently and meet sustainability targets.

“As green steel becomes more important and gains market share, we are obliged to deliver it for the future of our planet. Customers are starting to make sustainability a procurement criterion,” continues Max. “We therefore communicate a clear message to our suppliers: you need to work on your sustainability. Eventually, there will be sustainability requirements for all links in the supply chain, and if a supplier cannot meet those, we will not purchase from them even if they have the lowest price.”

Outokumpu Circle Green

Max is keen to tell us more about Outokoumpu’s revolutionary emission-minimised stainless steel, Circle Green. “Circle Green has the smallest emission intensity in the world, with up to 92% lower carbon footprint than the global average and up to 64% lower than Outokumpu’s regular production. No other manufacturer is able to produce flat stainless steel products with such low emission levels.”

The unprecedented emission reduction was achieved with improvements throughout the whole stainless steel production chain. Reductions in upstream raw material emissions were key to this success as they contribute the majority of stainless steel’s total carbon footprint. Meticulous production and quality optimisation have led to higher energy efficiency. Biogas, biodiesel, biocoke, and low-carbon electricity have been used in production to eliminate 95% of all scope 1 and 2 CO2 emissions. While these bio-based materials have all been tested previously in production, they were used together for the first time to produce Outokumpu Circle Green.

“In this first phase, we will concentrate our efforts on serving a few strategic customers, but we are ready and able to scale up the production. Circle Green has generated a lot of excitement within the company; the whole organisation is engaged,” Max enthuses. “We promise our customers when they select Circle Green that we are cutting the CO2 emissions against our conventional offerings by at least 50%. This makes it very tangible what is possible for CO2 management. If they pick us over other suppliers, the percentage is even higher!”

The first batch of Circle Green was delivered to Fiskars Group, a leading company producing design-driven indoor and outdoor living brands, for use in cookware products. “We already see significant demand for Circle Green in this sector,” explains Max. “These products are highly visible and tangible for consumers. The consumer goods market is one of the biggest consumers of stainless steel globally, so using sustainably produced steel will have an enormous impact. After all, we all own a washing machine and pots and pans. In the homeware store, it’s easy to identify pots labelled as being made from the most sustainable stainless steel.”

“Another key future market will be the automotive industry, which is pushing its supply chains to decarbonise. Choosing more sustainable materials will be a key way of achieving this.”

Demand for carbon footprint product information is growing in both the European and US markets, explains Max. “While demand is still stronger in Europe, our first shipments of Circle Green stainless steel will shortly be shipped to customers in the US. We are the first steel producer able to deliver green steel in significant volumes to the market. Other manufacturers are announcing plans, but these are for the future, not today. We can deliver green steel in significant volumes to help our customers decarbonise right now. We are ready to take on this pioneering role and transform the industry.”

Carefully controlled production chain

Many people are surprised to learn that Outokumpu did not need to make significant investments in new assets to achieve its remarkable carbon emission reductions, explains Max. “Outokumpu Circle Green steel is produced using the same assets as our conventional products. We already used electric arc furnaces, as we work with large quantities of scrap.” Further reducing the carbon footprint was achieved with a three-pronged approach:

- A selective approach to primary raw materials and controlling Scope 3 emissions by optimising the mix, e.g. biocoke to make ferrochrome.

- Using fossil-free energy throughout the production chain, e.g. biogas.

- Careful control of production to achieve very high efficiencies.

“Controlling every step of the process, from raw material selection through to how the production facilities are run, makes a huge difference,” comments Max.

Is this a strategy that other manufacturers can emulate? “Owning a chromium mine and ferrochrome production gives us a huge advantage as it provides access to a sustainable primary raw material. Furthermore, in Nordics, we have a high availability of fossil-free electricity. However, in the fight against climate change, which requires a global reduction in emissions, we hope that more manufacturers focus in this direction. We aim to educate the marketplace so that demand for sustainable steel grows and customers become more selective in the material they purchase.”

Towards a greener future

Max explains that Outokumpu’s overall goal is to integrate sustainability and product carbon footprints into every procurement decision.

“There is a need to educate and communicate with every link in the supply chain to highlight awareness. We’ve made great strides but continue to work on constant improvement. Our long-term climate target is to continue to reduce our direct and indirect CO2 emissions and those of our supply chain to achieve carbon neutrality by 2050.” To this end, Outokumpu is planning a significant investment in a biocoke and biomethane plant. If realised, the project would also significantly increase self-sufficiency in energy in Finland while potentially reducing CO2 emissions by over 200,000 tonnes per year. The project would be an important step towards the Finnish and European energy and climate targets for 2030.

“This will be an important milestone because producing biocoke and biomethane using forest waste is an extremely sustainable solution. We would essentially have our own biogas factory, enabling us further to increase our capacity to produce Circle Green stainless steel.”

Persistance and determination

Cutting back on carbon emissions in steel production requires persistence, determination and a willingness to invest, concludes Max. “Everyone knows that the energy transition is not going to be an easy process but at Outokumpu we are determined to play a positive role. The results we have booked so far will hopefully deliver inspiration elsewhere whilst we in our turn, certainly want to learn from the successes of others. Working together, we can forge a cleaner, greener stainless steel sector for the generations to follow. At Outokumpu, we are fully focused on working towards a world that lasts forever.”

About this Featured Story

This Featured Story appeared in Stainless Steel World March 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.