Text & images by TWI

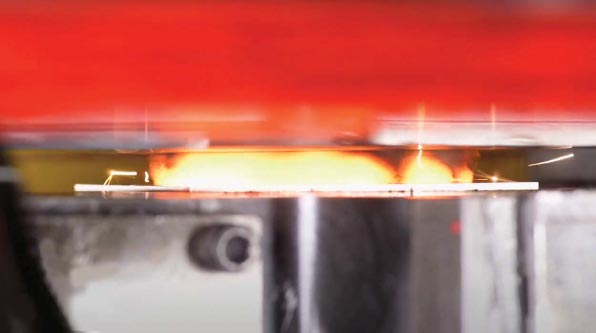

TWI announced the start of the production of complex aerospace parts through linear friction welding. Linear friction welding is an emerging technology for the manufacturing of titanium and aluminium alloy aerospace components.

High integrity welded components can be produced within seconds through linear friction welding (LFW). TWI’s LFW machine, of 250 kN capacity, has been used to produce the first batch

High integrity welded components can be produced within seconds through linear friction welding (LFW). TWI’s LFW machine, of 250 kN capacity, has been used to produce the first batch

of aerospace parts. This activity is part of the TOD Clean Sky project, which focuses on the development of full-scale innovative doors, surrounds and sub-structures for regional aircraft fuselage barrel on-ground demonstrators.

The TWI coordinated project is funded as part of the Clean Sky initiative under grant agreement number 821192. The collaborative consortium also includes the Topic Manager Leonardo, DEMA and CETMA.