A recent independent study leaves no room for doubt: Aperam’s DX2202 (1.4062) grade of lean duplex stainless steel offers similar localised corrosion resistance as the 316L austenitic grade (in the environment used for this study). As a result, and in addition to its price competitiveness, lean duplex DX2202 is a good candidate to replace 316L in water treatment applications.

Text & images by Aperam

The independent study was led by the French Corrosion Institute and done in collaboration with Veolia, a leading environmental engineering company with a deep expertise in water and wastewater treatment applications. To learn more about what this study means for stainless steel, Aperam, and end users, Stainless Steel World sat down with Dr. Audrey Allion, who co-authored the report, and Dr. Charles David, who heads Aperam’s lean duplex customer technical support team.

Why was this independent study carried out and how was it organised?

Dr. Allion: When it comes to wastewater treatment applications, Lean Duplex stainless steels are well-positioned to serve as a good alternative to the more commonly used austenitic grades. However, despite the advantages they offer, uptake remains low – probably due to the fact that there are very few – if any – case studies on using duplex grades in wastewater applications.

This study aimed to change that by clearly defining the limits of using lean duplexes for urban wastewater treatment units. The study is an initiative of seven partners, including two of Europe’s leading stainless steel manufacturers, Aperam and Outokumpu, and end-user Veolia. It was led by the French Corrosion Institute.

What is localised corrosion, and why is it important for such applications?

Dr. Allion: Uniform corrosion in stainless steel is usually negligible, down to a pH of about 4, meaning it is not an issue for most types of environments. However, localised corrosion can occur depending on factors such as temperature, pH, aggressive ion concentration (mainly chloride) and the composition of the stainless steel.

For instance, crevice corrosion is a type of localised corrosion that often occurs in an application’s confined spaces (i.e. crevices). Because these spaces have limited access to the oxygen needed for repassivation, the phenomenon that forms the protective layer that allows the material to resist corrosion, crevice corrosion occurs. This also increases the aggressive anion content, which creates a harsher environment. As a result, localised corrosion has traditionally been a key factor in stainless steels’ wide-spread use with wastewater treatment applications.

What are the main outcomes of the study?

Dr. Allion: This study compared the localised corrosion performance of the selected lean duplexes to that of austenitic grades 304L and 316L (and with DX2304 and DX2205). The materials underwent field testing in municipal wastewater plants (WWTP) for a period of one year, during which they were subjected to both low and high chloride content units, representative of standard and harsh conditions. Samples of each grade were also fully immersed in the pre-treatment buildings located at the inlet works (the screen step used to remove large particles). Concentrations of chloride and H2S were about ten times higher in the harsh WWTP than in the standard one. We found that similar localised corrosion resistance was observed between the 316L and DX2202 grade samples featuring crevice configuration or welded coupons. The study also included substantial lab tests that used simulated water systems based on Veolia’s recommendations. These simulated lab tests provided similar results to what we gained from our field tests, further verifying our testing methods – and results.

Are there other advantages of using DX2202?

steels.

Dr. David: Like other duplexes, lean duplexes differ from other stainless steel grades in that their microstructure has two phases instead of just one. Similar to composite materials, this dual-phase structure gives lean duplexes mechanical properties that simply cannot be obtained when each material is

used separately. This is why these grades have about twice the mechanical resistance as their austenitic counterparts, allowing thickness reduction in some cases.

How can lean duplexes perform so well when their nickel content is so low?

Dr. David: When it comes to corrosion, stainless steel’s behaviour mostly depends on its chromium content. The higher it is, the stronger the chromium oxide layer and the better it is able to protect the metal from corrosion initiation. Advancements in the industrial techniques for producing stainless steel have allowed us to merge the best of two worlds: excellent mechanical properties without the need for high nickel content, and high corrosion resistance thanks to the possibility of increasing the chromium percentage (see Figure 1).

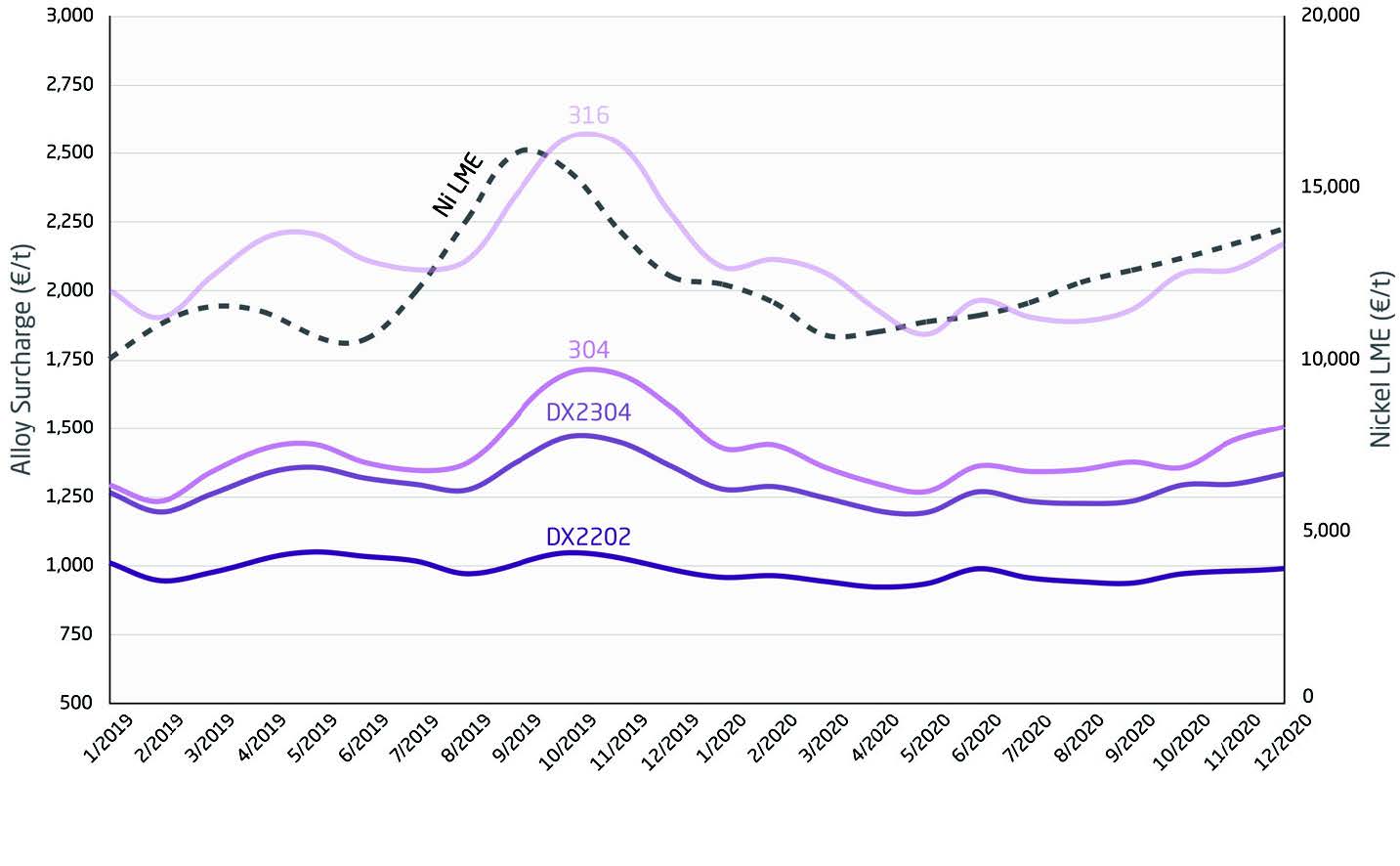

What about DX2202’s price competitiveness? Does it offer economic advantages over austenitic grades?

Dr. David: Because DX2202 replaces the mechanical contribution of nickel with a dual-phase structure, it is able to offer considerable savings in terms of raw material cost. Despite the fact that lean duplex grades require unique know-how and special production methods, the resulting enhanced corrosion resistance makes for a very competitively priced stainless steel. In this way, DX2202 is often cheaper than 304L and 316L, especially when the nickel price is high. Furthermore, lean duplexes are much less impacted by nickel price fluctuations, as illustrated in Figure 2.

Dr. Audrey Allion

Audrey Allion has a Ph.D. in microbiology and physical chemistry from AgroParisTech. Her studies focused on the interfaces between materials and the environment and were done in collaboration with France’s National Research Institute for Agriculture, Food and Environment (INRAE). Since 2004 she has worked as a researcher at Aperam’s Isbergues Research Center. As part of the Center’s Solutions Department, Audrey oversees projects dealing with how stainless steel’s surface interacts with the surrounding environment (corrosion, biofouling, biocorrosion, food contact compatibility) in various industrial applications.

Dr. Charles David

In addition to leading project sales at Aperam, Charles David is also involved with the commercial development of the company’s special grades – including those used for water/wastewater, construction, oil & gas and nuclear power applications. Before joining the sales team, Charles spent six years working as a researcher at Aperam’s Isbergues Research Center. He holds an engineering degree from ENSC Lille and a PHD in materials engineering from the University of Grenoble.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.