Guest Author: Andry Soetiawan

Dear Materials & Corrosion Engineers,

This column for Stainless Steel World is, I believe, very relevant in the current global economy where cost reduction is paramount. After all, corrosion simply does not care about recession.

The topic I would like to raise is the wider use of lean duplex stainless steel. This group of alloys is currently less well established in the oil and gas industry despite strong advantages when compared to its austenitic stainless steel counterparts such as 304/L and 316/L.

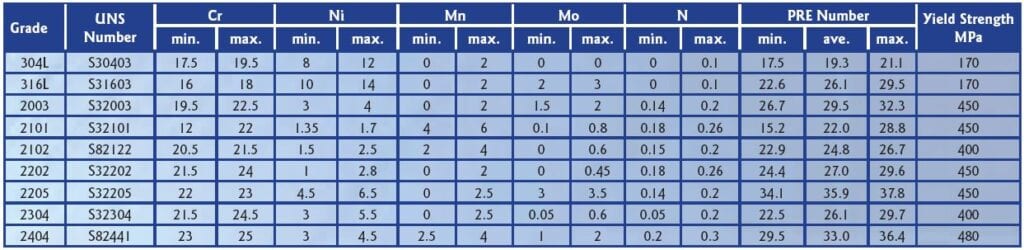

Lean duplex is a member of the duplex family. These alloys typically have a PRE number below 30, with a reduced amount of higher priced and more volatilely priced alloying elements such as nickel and molybdenum, aiming to substitute 304/L & 316/L in more applications.

To maintain desirable corrosion properties and phase balance, other alloying elements are increased in

the chemical composition, such as chromium, manganese and nitrogen. Per my knowledge, lean duplex is already quite popular for structural applications such as tanks, buildings, and bridges. However, it is my sincere wish to see more usage in the future in both the upstream and downstream oil and gas sectors, as well as in chemical, petrochemical, and food industries, etc.

Advantages of lean duplex

Below are some advantages that I can see from using lean duplex:

1. The main reason for using lean duplex is its significant resistance to chloride stress corrosion cracking because of its dual phases. As a general rule of thumb, the corrosion resistance of lean duplex is likely to be similar to 304L and 316L with corresponding PRE numbers.

2. The yield strength of duplex is more than twice that of 304L and 316L hence the wall thicknessof equipment or piping can be reduced. Less thickness also means lower weight which can significantly help as regards transportation and installation, especially in remote or offshore locations.

3. Lean duplex benefits from a lower CAPEX. Alloying elements such

as nickel and molybdenum carry a high price, which drives up the relative cost of 304L and 316L. The reduction of both these elements keeps lean duplex economical. And with an almost similar price per unit weight, designing lean duplex equipment with lower thicknesses can significantly reduce the total cost.

Limitations

However, there’s no such thing as a perfect material and hence there are some imitations to be aware of when considering lean duplex:

1. The design temperature range depends on the lean duplex grade but is normallybetween minus 50°C to 300°C. Higher temperatures may risk intermetallic formation and lower temperatures may risk brittle fracture.

2. Be prepared for additional delivery time because less material is kept in stock and not all product forms may be available. This is a question of supply and demand but it is hoped that, with the further acceptance and usage of lean duplex by more companies, this problem can be solved in the future.

3. With a PRE < 30 and Mo < 1.5%, the use of most lean duplexes in sour upstream environments is in practice not compliant with NACE MR0175. Fortunately, this is not a problem in downstream usage where NACE MR0103 has no issue, as all duplexes are treated equally.

Additional notes

1. The duplex family achieve their phase balance and pitting corrosion resistance from nitrogen. During welding, some nitrogen is released from the metal so the use of nitrogen-containing gas is recommended.

2. The corrosion and mechanical properties of duplex are achieved with a ferrite/austenite phase balance of 40 – 60%.

3. Although the yield strength of lean duplex is more than double compared with austenitic, the allowable stress for design calculation is not.

To see additional supporting images, please consult the online version of this article available on the website https://tinyurl.com/y3hdw5b7

Meet the author: