Azoth 3D, a precision Additive Manufacturing parts maker based in Ann Arbor, Michigan, USA, will expand its production capabilities with a Hammer Lab35, a lithography-based metal manufacturing (LMM) machine from Incus GmbH, Vienna, Austria. This collaboration is expected to enable Azoth 3D to deliver small, complex metal parts with shorter turnarounds.

Azoth stated that the adoption of Incus’ LMM technology marks a significant step forward in its mission to provide high-quality metal components with shorter lead times, increased design freedom, and cost efficiency. It will focus its work on 316L and 17-4 PH stainless steels and titanium.

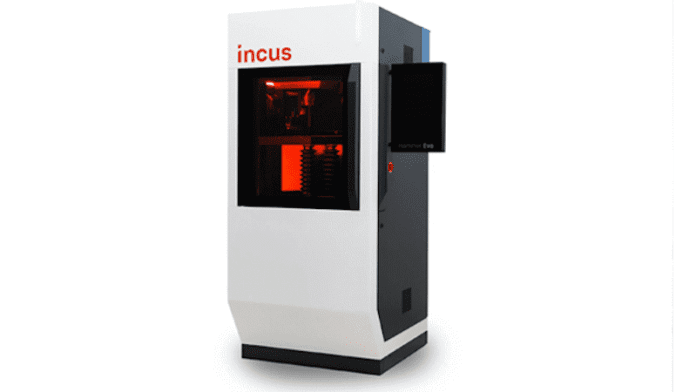

The Hammer Lab35 machine utilises a photopolymerisation-based process to achieve its fine feature resolution and surface finish, making it well-suited for complex geometries and intricate designs.

The integration of Incus’ technology further strengthens Azoth 3D’s commitment to delivering cutting-edge Additive Manufacturing solutions and reducing supply chain constraints.