By Hiro Watanabe, Sanyo Seiki Co., Ltd. Japan

Various roll forming methods are available to produce welded stainless pipes. While W-Bend Forming and PSF (Partial Step Forming) techniques are now considered the standard, these methods were seen as novel and ground-breaking when first developed.

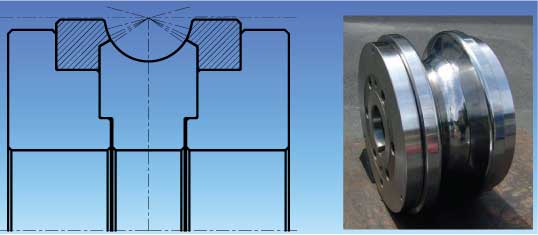

During the manufacture of welded stainless steel pipes, it used to be essential to achieve a uniform structure by applying a heat treatment process before bending and other secondary processing. However, the introduction and running cost of heat treatment processes are high. Sanyo Seiki, a forming roll manufacturer in Japan, invented Partial Step Forming (PSF) and contributed to removing the heat treatment process.

The same roll maker also invented and developed W-bend forming. This technique brought about an enormous improvement in seam weld quality in the production of welded steel pipes. PSF methods were developed by focusing on the characteristics of stainless steel, the quality of the final products, and reducing customer’s manufacturing costs.