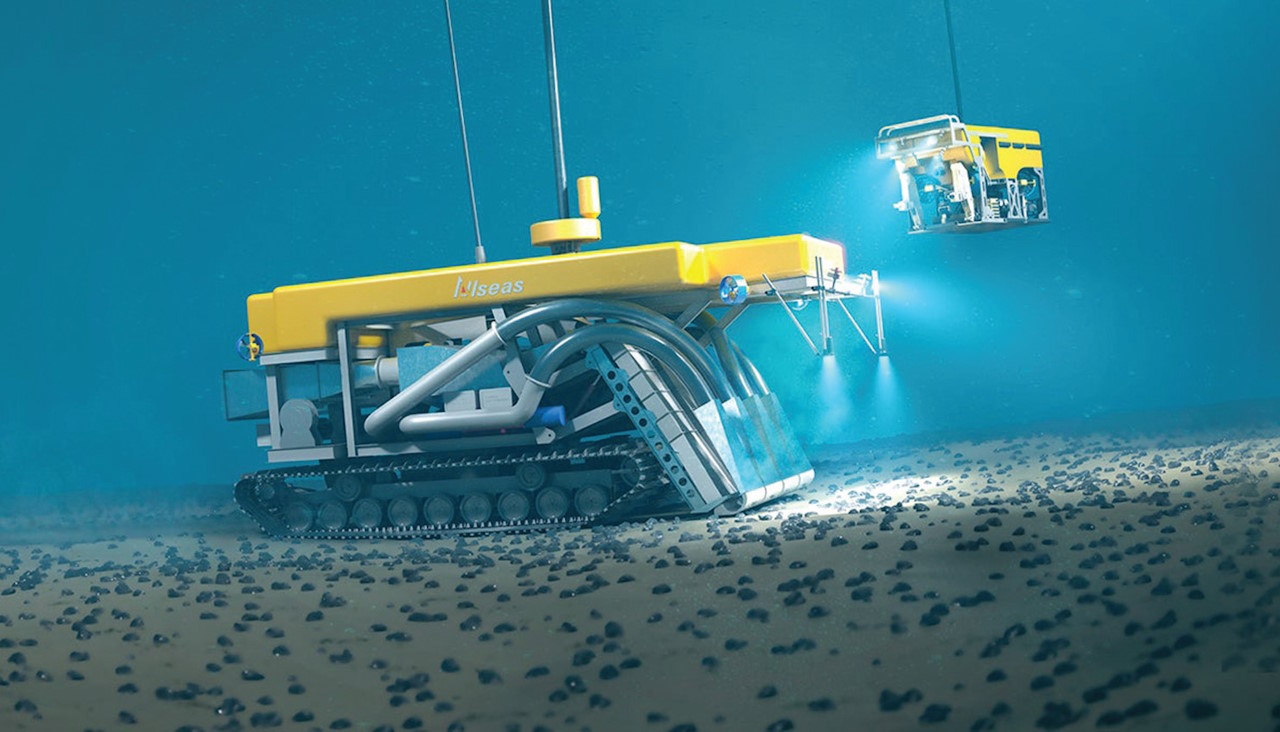

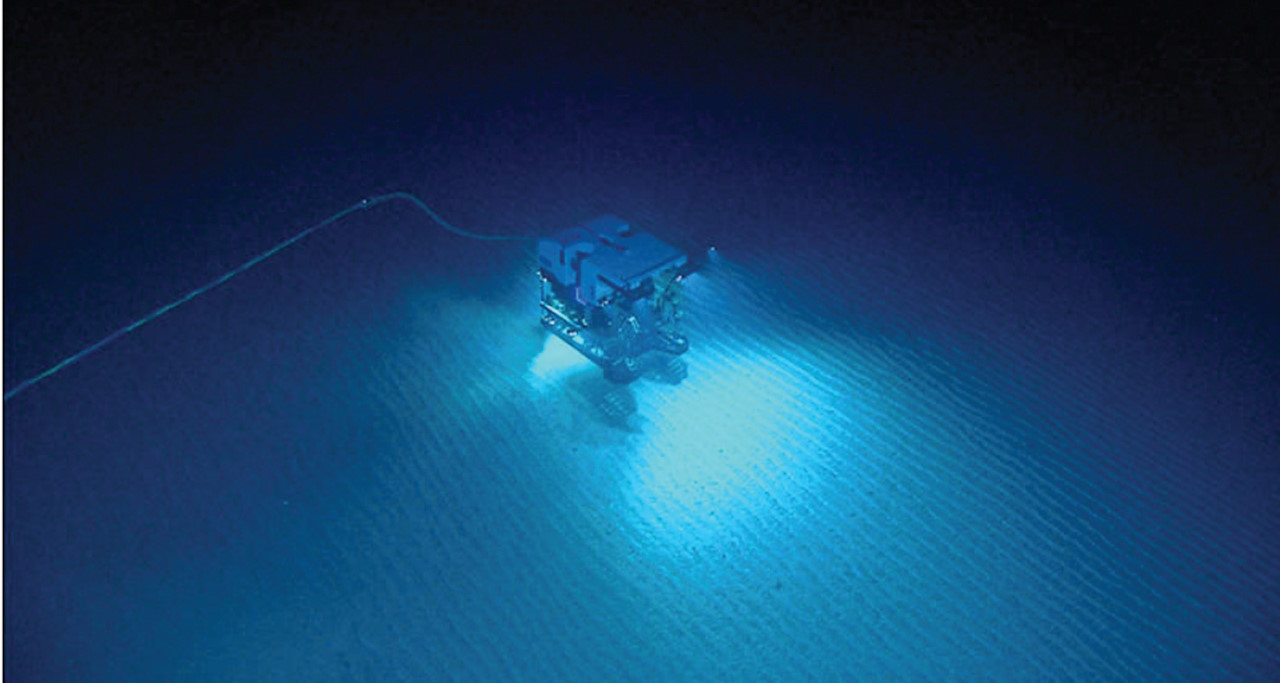

An artists representation of deepsea mining of polymetallic nodules on the seabed. Source: Wikimedia, Gringo from Zemgale https://creativecommons.org/licenses/by-sa/4.0/deed.en

Duplex stainless steel is a cost-effective material for the deep-sea environment, suitable for equipment such as subsea pipelines, flowlines, umbilicals, risers, offshore platforms, marine structural components, marine hardware, valves, fittings, and desalination systems.

By Srikumar Chakraborty, ex ASP/SAIL, Freelance Consultant

Deepsea minerals

Critical minerals such as lithium, cobalt, nickel, and rare earth elements play an indispensable role across a broad spectrum of industries, powering technologies from wind turbines and electric vehicles to smartphones, medical devices, and military systems. While land-based extraction of these resources is well established, rapidly growing demand is driving renewed interest in the vast, mineral-rich deposits found on the ocean floor.

Several nations have already begun investigating subsea mineral resources and evaluating emerging deep-sea mining techniques. Nevertheless, much of the deep ocean remains poorly understood and largely unexplored. The prospect of commercial deep-sea mining remains highly controversial, with scientists and environmental groups raising serious concerns about the potential impacts on marine ecosystems and broader planetary health.

Characterististics of seawater

Marine and subsea environments present distinct material challenges arising from salinity, variable density, temperature fluctuations, and the presence of dissolved compounds. Seawater consists of approximately 96.5% water and 3.5% dissolved salts, primarily sodium chloride (NaCl), along with notable concentrations of magnesium, sulfate, calcium, and potassium. It also contains dissolved gases, including oxygen, nitrogen, and carbon dioxide. Salinity plays a critical role in influencing key physical properties of seawater, such as density, freezing point, and chemical reactivity, all of which can affect both material performance and interactions with marine life. Moreover, density is further modulated by temperature, with colder waters exhibiting higher density—an important consideration in the design and longevity of materials exposed to deep-sea conditions.

Progress of deep-sea mining

Countries including China, Japan, South Korea, France, and Norway are actively pursuing deep-sea mining, holding or seeking exploration licenses from the International Seabed Authority (ISA) under the United Nations Convention on the Law of the Sea (UNCLOS). Established in 1994, the ISA regulates mining activities in international waters, balancing resource development with environmental protection for the benefit of humanity.

Interest in deep-sea mining is driven by growing demand for critical minerals used in electric vehicle batteries, renewable energy infrastructure, electronics, and metal industries. Targeted resources include polymetallic nodules, seafloor massive sulfides, and cobalt-rich crusts, which contain valuable metals such as manganese, nickel, cobalt, copper, and rare earth elements.

Deep-sea mining remains in the exploration phase, with no commercial operations to date. While the ISA has issued exploration contracts, regulations for full-scale exploitation are still under development. China has emerged as a key player, securing multiple ISA contracts and investing heavily in deep-sea mining technology. Supported by strong state backing, China leads in exploration efforts but faces scrutiny over environmental impacts and evolving international regulations.

An artists representation of deepsea mining of polymetallic nodules on the seabed. Source: Wikimedia, Gringo from Zemgale https://creativecommons.org/licenses/by-sa/4.0/deed.en

What is duplex?

Duplex stainless steels are distinguished by their two-phase microstructure, comprising approximately equal proportions of austenite and ferrite. While the nominal target is a 50/50 distribution, commercial alloys typically exhibit slight variations, with phase balances generally falling within the 40/60 range. Duplex stainless steels offer corrosion resistance comparable to austenitic grades but provide superior resistance to stress corrosion cracking—particularly in chloride-rich environments—alongside significantly higher tensile and yield strengths, with yield strength approximately double that of standard austenitic stainless steels.

Chemically, duplex grades are characterised by very low carbon content (typically less than 0.03%), chromium levels ranging from 21.00 to 26.00%, nickel from 3.50 to 8.00%, and molybdenum up to 4.50%. Their toughness and ductility fall between those of austenitic and ferritic stainless steels. Duplex stainless steels are generally classified into three categories based on corrosion resistance: lean duplex, standard duplex, and super duplex. Super duplex grades exhibit enhanced mechanical strength and superior resistance to pitting, crevice corrosion, and stress corrosion cracking compared to both standard duplex and austenitic grades.

Duplex stainless steels are widely used in demanding applications such as marine structures, petrochemical and desalination plants, heat exchangers, and the pulp and paper industry.

The duplex family is ideally suited to demanding deep-sea mining applications.

Characteristics of duplex

Duplex products offer a unique combination of high strength and excellent corrosion resistance due to their dual-phase microstructure. Their approximately twofold strength advantage over austenitic and ferritic grades makes them ideal for weight-reduction strategies while ensuring durability in harsh environments. Duplex steels demonstrate excellent resistance to localised corrosion forms, including pitting and crevice corrosion, as well as exceptional resistance to chloride-induced stress corrosion cracking.

They also maintain good mechanical performance at low temperatures (down to –50°C) and up to moderate temperatures (generally below 300°C). With proper welding techniques, duplex stainless steels achieve reliable weldability while preserving their advantageous microstructure and mechanical properties. However, their high strength and work-hardening characteristics can pose challenges in machining, particularly in structural applications. The elevated yield strength enables the use of thinner wall sections, reducing overall material weight and contributing to cost efficiency in fabrication and installation.

A bed of manganese nodules from deep offshore of the Cook Islands; photo sourced from Hein et al., 2015, taken during a Japanese research cruise in the year 2000. Nodules range from about 2 to 10 centimeters across. Source: https://www.usgs.gov/media/images/cook-islands-manganese-nodules

Fabrication characteristics

Corrosion resistance: Duplex stainless steels offer excellent corrosion resistance, particularly in chloride-rich environments like seawater, making them ideal for subsea and offshore applications.

Fatigue resistance: High fatigue strength makes duplex steels well-suited for cyclic loading applications, including risers, umbilicals, and other dynamic structures.

Weldability, cutting, and bending: Duplex grades combine strength with good formability and weldability. Bending requires greater force than austenitic grades but proceeds similarly beyond the yield point. Cutting demands appropriate tooling to avoid heat-affected zone (HAZ) issues, while welding necessitates strict heat input control to preserve microstructure and prevent cracking.

Cost efficiency: The high strength of duplex stainless steels enables reduced wall thickness, lowering material consumption. Combined with good weldability, formability, and long-term corrosion resistance, duplex steels offer significant life-cycle cost savings, particularly in demanding marine and subsea environments.

Categories of duplex

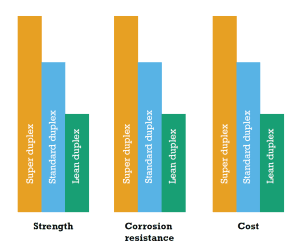

Duplex stainless steelsare classified into lean, standard, and super duplex grades, each offering varying levels of strength and corrosion resistance to suit specific seabed mining applications.

- Lean Duplex (21–23% Cr, 1–3%Ni, low Mo and N) provides good corrosion resistance at a lower cost, with easier weldability due to reduced alloying. Grades like 2304 are ideal where moderate corrosion resistance and high strength are sufficient.

- Standard Duplex (22–25% Cr, 3–6.5% Ni, moderate Mo and N) strikes a balance between mechanical strength and corrosion resistance, making it suitable for a wide range of subsea applications.

- Super Duplex (25–27% Cr, 6–8% Ni, higher Mo and N) offers superior corrosion resistance and mechanical properties. Grades like 2507 excel in highly aggressive environments, such as deep-sea mining and high-chloride conditions.

Conclusion

Duplex stainless steel is widely used in deep-sea applications – including subsea pipelines, umbilicals, risers, marine structures, and desalination systems – due to its strength, corrosion resistance, and cost-effectiveness. While it offers an excellent balance of properties, alternative materials such as super duplex stainless steels and nickel-based alloys are often preferred in more extreme environments. Ultimately, duplex stainless steel remains a proven, reliable option for many critical components in seabed mining operations.

References

- Summer XU, Head of Overseas Markets, Nickel Alloy

- Oliver Ashford et al, World Resource Institute

- International Seabed Authority,

- China’s Progress, ISA,

- ASTM/AISI,

- Advances in Stainless Steel Metallurgy and Advanced Science by BaldevRaj et al.(Indian Scientist & Metallurgist)

About this Tech Article

Appearing in the November 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.