To maintain good corrosion properties of duplex stainless-steel welds, it is of critical importance to minimize the loss of nitrogen in the weld metal, particularly in super duplex stainless steels (SDSS) with very high nitrogen content. However, it can be difficult to retain a correct amount of nitrogen in the weld metal when welding with SDSS filler metals, even when adding nitrogen to the shielding and backing gas.

In stainless steel, pitting corrosion resistance (PRE) is a known empirical approach to link the composition to corrosion resistance properties. Stainless steels are normally ranked based

on this number to be used in different applications.

In duplex stainless steel, PREN (PRE considering nitrogen content; PREN=Cr+3.3Mo+16*N) is highly dependent on the nitrogen content in the weld metal. Nitrogen is also used to promote the formation of primary austenite after the melt pool solidifies. If the nitrogen content is too low, less austenite will form. This results in the primary weld metal having too high ferrite content compared to the thermodynamic equilibrium. The reheating from the subsequent welding passes will cause a phase transformation from ferrite to austenite, bringing the system closer to equilibrium and reducing the total energy in the system. This austenite is called secondary austenite, γ2. However. The Cr, Mo, and N content is lower in the γ2 compared to the primary austenite [1]. As shown above, these three elements are in the PREN equation, causing the γ2 phase to be more susceptible to corrosion attacks.

The 2507 SDSS base material and the SDSS filler metal have similar PREN. Therefore, if nitrogen is lost during the welding there is a risk that the corrosion resistance of the weld metal will become lower than that of the base material, as explained above. This is not ideal, as corrosion tends to target the least noble material in a system. This is especially important when the surface area is small, such as the area of the weld root compared to the area of the surrounding base material. Also, the irregular shape of the weld bead is unfavourable to the corrosion resistance.

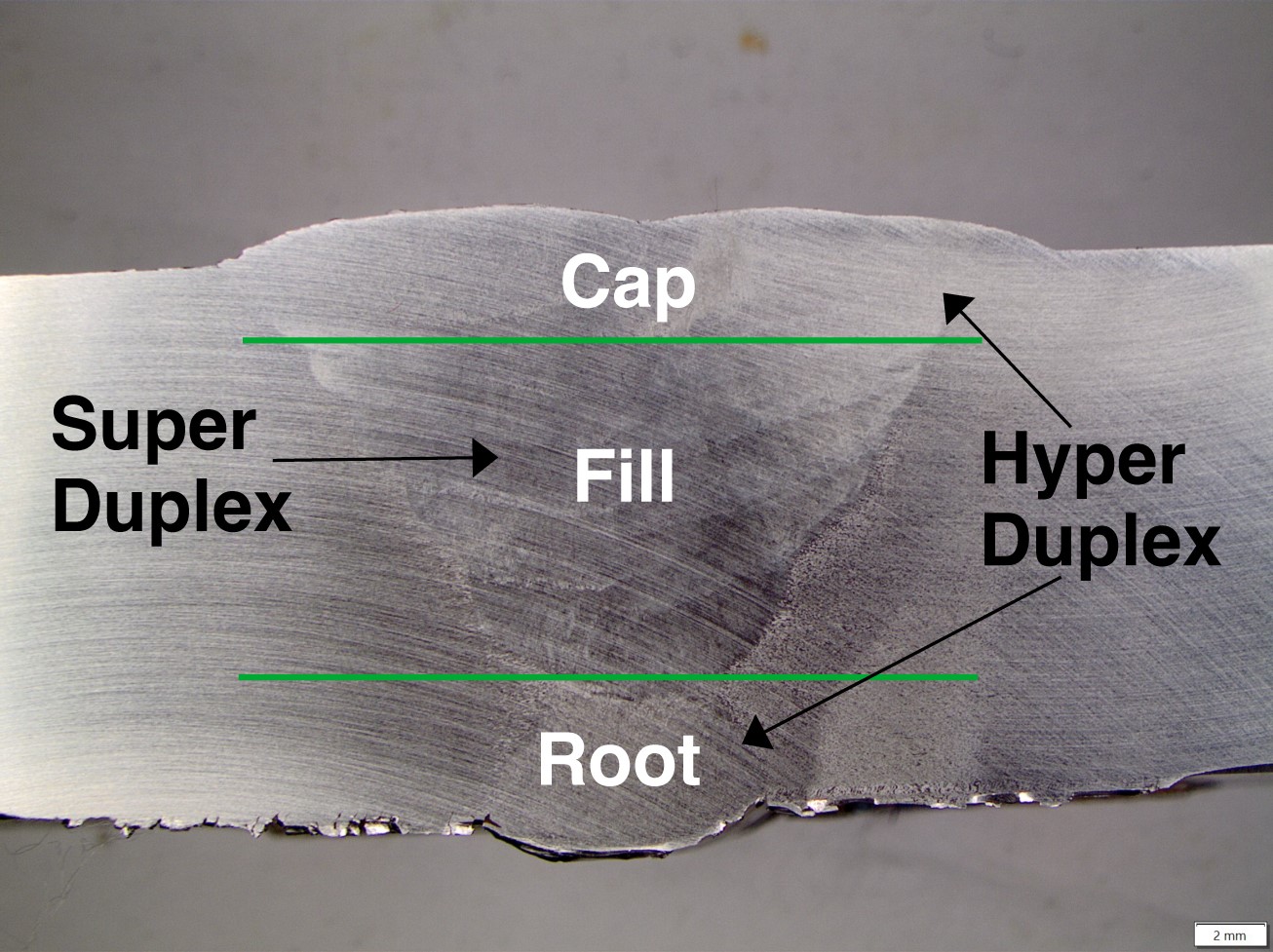

Hyper duplex stainless steel (HDSS) is a relatively new alloy compared to super duplex stainless steel. This alloy has high corrosion resistance in combination with high mechanical strength. The PREN for the HDSS filler metal is typically 49 thanks to its higher Cr and N contents. By using an HDSS filler metal in the root and capping passes of SDSS welds, it is possible to increase the corrosion resistance in the places that matter the most, the exposed weld surface. The high chromium and nitrogen content in the HDSS filler metal yields higher PREN at the exposed outer surfaces, even with considering base metal dilution.

ESAB have made tests in 15mm thick 2507 plates that show that it is possible to increase the mechanical properties as well as corrosion resistance by welding with HDSS on the root and cap. Figure 1 shows a cross section of one of the tests. In the G48 Method A test at 50°C, the samples welded with HDSS in the root and capping passes had roughly one order of magnitude lower corrosion rate than the sample welded with solely SDSS filler metal. There were also minor gains in the mechanical properties of the weld metal, where the impact toughness and tensile strength increased slightly compared to pure SDSS weld metal. In addition, the ferrite content in the root and cap were 40% and 58% respectively, which are in the acceptance range of all standards. Therefore, for critical applications, it is possible to use HDSS filler metal to get higher corrosion performance in SDSS joints.

[1] V. A Hosseini, L. Karlsson, D. Engelberg,and S. Wessman, “Time-temperature-precipitation and property diagrams for super duplex stainless steel weld metals,” Welding in the World, vol. 62, no. 3, pp. 517–533, May 2018, doi: 10.1007/s40194-018-0548-z.

Meet the columnist: Dr Edwin Bergstedt

Dr Edwin Bergstedt joined ESAB in 2021 and is part of the Applications Engineering team at ESAB Gothenburg. Edwin is a welding engineer, IWE. He received a doctoral degree in tribology in 2021 and has a MSc in materials science.

About this Tech Article

Appearing in the November 2024 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.