Frost-proof wastewater pipe on the Kitzsteinhorn, Austria. Two Eigerflex Longline pipes from Brugg Pipes were used at an altitude of up to 3,000 meters between June and October 2023.

Water is a vital resource which is present in unchanging quantity, but only a small fraction of it is accessible and fit for human consumption. New technologies – including efficiency gains, recycling and automation – can be harnessed, and stainless steel is a vital part of the drive towards producing smarter water.

By James Chater

Background

The earth contains an estimated 1,386 million cubic kilometres of water. This level is constant; none of it escapes the earth’s atmosphere. There is a theory that this water comes from asteroids and comets that collided with earth; whatever the truth, for the last few billion years, the figure has remained constant. However, it matters to human beings what form the water is found in.

It can be in different phases (ice, liquid, vapour); most of it is unfit for consumption, because it is saline or contaminated; and some of it is difficult to access (for example, in glaciers or underground). All in all, only about 0.001% of water is readily available for human use. This partly explains why, in a world facing heavy population pressures, around 2 billion people do not have access to clean and safe drinking water, while 46% of the world’s population lacks adequate sanitation services.

Water availability is influenced by several factors: political, ecological, etc., and many of the solutions are not a question of technology per se. For instance, carbon emissions cause global warming that gives rise to erratic weather patterns; planting trees can help fix the water in the ground; mobile laboratories or public transport can make it easier for rural populations to gain access to a water.

Technology

However, technology can make a great deal of difference in a number areas, including efficiency gains, recycling and automation.

Efficiency gains: Whether in terms of energy consumption, water consumption or carbon footprint, the latest wastewater and desalination plants are much more efficient than the older ones. Veolia’s seawater desalination plant at Hassyan, UAE, due to go online in 2026, will be powered by solar energy and consume a low 2.9 kilowatt-hours per cubic metre, confirming the progress of RO plants, which have reduced energy consumption by 35% over the last 10 years. The modernization of Veolia’s Greater Lyon wastewater treatment plant at Saint Fons will see a reduction in electricity consumption by 10%, gas consumption by 72% and chemical additives by 50%. Waste heat recovery from nearby incinerators will replace fossil fuels. These are examples of Veolia’s 2024-7 “Strategic Program”, which aims for efficiency gains in its water management and energy consumption.

Drought and tourism

Part of the appeal of Mediterranean countries is their hot, dry climate. But this places them in a dilemma. Large parts of Sicily are so parched of water that they have been virtually reduced to desert. So farmers in this region are thinking of replacing their olive and wine production with more drought-resistant African-style foods. In Greece, prolonged drought has reduced the potato harvest to half that of previous years. The pressure from tourism merely adds to the number of people needing to slake their thirst during the hottest months of the year. But tourism is a major source of income. What to do? The answer is probably to invest in desalination, as is occurring already on the Greek islands.

Desalination is rapidly emerging as a means to ensure adequate supplies of drinking water, especially in dry regions such as the Arabian Gulf.

A major problem is what to do with the salt once it has been extracted.

Discharge back into the sea is scarcely an option given the threat to marine life, while disposal on land harms the soil and vegetation. Solutions have been proposed by MIT, which is studying a process of converting waste materials into useful chemicals, including ones that increase the efficiency of the desalination process itself. The process produces sodium hydroxide (caustic soda) that pretreats the seawater before desalination, making it less acid and so less corrosive. Another chemical that can be produced is hydrochloric acid, which can be used to clean parts of the desalination plant and is also a source of hydrogen. The increasing synergy between the desalination and chemical industries can be seen in the concentration in brine of not only salt but chemicals such as magnesium, potassium and bromine that can be nano-filtered out and recycled in chemical plants. Other important trends improving the efficiency of water treatment include portable desalination and air-to-water plants. Although desalination plants are getting bigger, remote locations, yachts and off-grid locations require micro-solutions (similar to the current trend towards smaller nuclear plants). MIT is working on a system to remove particles and salts through electricity, eliminating the need for filters and high-pressure pumps. Furthermore, it is now possible to produce water from moist air. France’s Eole Water is pioneering this by using a modified wind turbine design. Air is sucked into an electric cooling processor, where the moisture is extracted and condensed into water. The device works even in drier climates: Eole’s prototype in the Abu Dhabi desert produces 62 litres per hour.

Recycling: Treated wastewater is widely used in irrigation and industry. This requires removal of sediment, bacteria and micropollutants. What is relatively new is recycling of water for drinking. This is still little known in the cooler regions of the north, but in the water-stressed tropical and southern regions it is catching on: examples include Namibia, Australia, California, Texas and Singapore. But France, Spain, Portugal and Greece are prone to drought as well, and it is only a matter of time before recycled drinking water, unappetizing though it may sound, will be introduced there. In an effort to overcome negative emotions over this issue, in 2018 Sweden’s IVL Swedish Environmental Institute, Nya Carnegie Brewery, and Carlsberg Sweden launched PU:REST, a beer made with recycled water. A year later in Germany, Reuse Beer, also made from recycled water, was launched but is no longer being produced.

Automation: Information technology (including AI) is an integral part of the drive towards efficiency. When Shenzhen (China) modernized its water supply a few years ago, it installed a smart control system uniting the primary (mains) and secondary systems. The latter were equipped with meters and cameras to monitor flow rates and performance of valves and pumps. Veolia applies smart monitoring solutions to protect water networks. These speed up the information-gathering process, allowing instantaneous decision-making. The KAPTA™ 3000-AC4sensors collect physico-chemical data (conductivity, pressure, temperature and chlorine content) to warn of problems such as leaks, corrosion, clogging or contaminants.

Water and the Olympics

As part of the preparations for the Olympics in Paris this summer, 1.4 billion euros were spent on a massive clean-up of the long-polluted river Seine. This allowed some of the swimming races to be held in the river. (However, some of the participating athletes were taken ill and hospitalized.) A huge water overflow and storage basin was built in the area round the Gare Austerlitz in the heart of Paris. With a capacity of 20 Olympic swimming pools (50,000 cu m), it captures and stores dirty water and redirects it towards a treatment plant where it is cleaned before being released into the river. This prevents untreated water from overwhelming the treatment facilities and polluting the Seine.

Other newly built facilities include a water treatment plant in Champigny-sur-Marne, east of Paris. A floating swimming pool with gym, “Annette K”, was also built for the Olympics. The suspended pool, resembling a ship’s hull, was built of wood, glass and stainless steel. Italy’s Myrtha Pools also installed two modular stainless-steel swimming pools at La Defense Arena, for the swimming and water polo events. The pools use 47 tonnes of the Italian company’s stainless-steel components. Because swimming pool water is chlorinated and warm, type 316L is standard in items such as piping, attachments and rails.

Materials

“304 or higher” is standard in the specification of stainless steel in water projects. In practice this means that austenitics 304(L) and 316(L) are the most commonly applied grades in pipes, storage tanks, valves and pumps. This was not always the case: in the past, concrete, bamboo and wood were among the materials used. In China, secondary water systems were traditionally made with galvanized steel, ductile iron or plastic, which are all prone to leak. The ambitious Shenzhen modernization project used 304 and 316, and although the older materials persist in existing infrastructure, 316L is now standard in nearly all modern upgrades and new-builds. A significant growing market is district heating pipes, where stainless is applied in both in the primary circuit connecting the power station to the substations and the secondary circuits within the buildings.

The duplex family of stainless steels play an indispensable role in more demanding applications. The modes of use can be divided into two types of service: handling corrosive or erosive substances such as wastewater of saltwater; and providing lightness and strength in floodgates. Desalination, a chemical process, requires various duplex and superduplex grades. The most demanding environments, combining heat, high pressure and corrosion, are found in the energy-intensive MED and MSF plants, especially at the brine water intake stage. Depending on specific factors, superduplex type 2507, lean duplex LDX 2101, superaustenitic 254 SMO and austenitic 316L all come into play.

Duplex grades are also used in wastewater treatment processes, where high strength and resistance to erosion and corrosion are required. A recent example of its use in Barhale’s work for Thames Water on sewerage in East London, where duplex was applied on wastewater pipes.

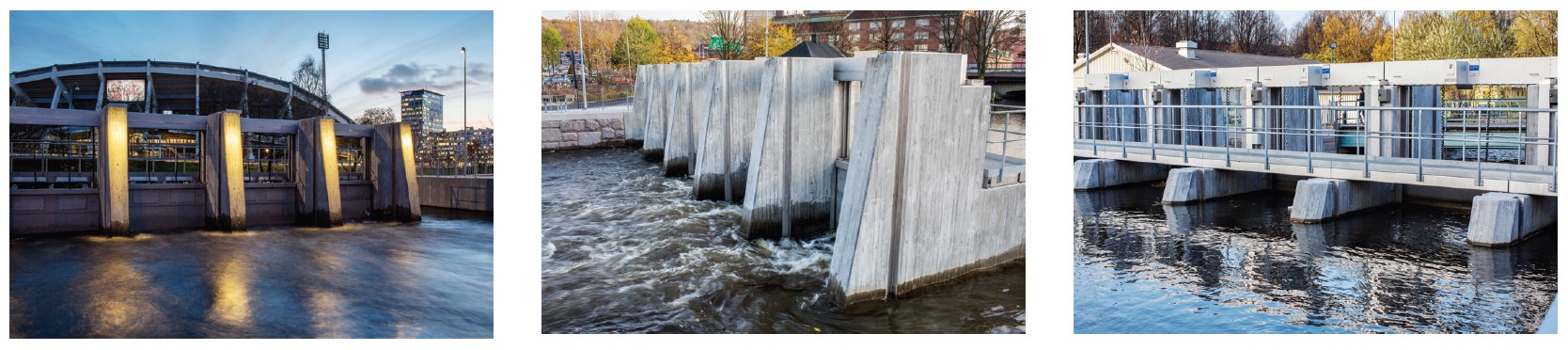

Another application requiring duplex is floodwater management. Municipalities are turning more and more to these grades for floodgates, where not only resistance to saline corrosion but also a favourable strength-to-weight ratio are required. Projects include:

Tammerkoski rapids, Tampere, Finland (completed in 2012). The wooden floodgates had to be replaced, and at first carbon steel was envisaged. But in the end Outokumpu’s Forta LDX 2101 lean duplex grade was applied in the main structural parts of the gates.

Gårda Dämme, Gothenburg, Sweden. In 2013, Outokumpu supplied its Forta LDX 2404 lean duplex grade to replace wooden gates. The coastal city is built on islands intersected by canals, and flooding is a great risk. The new gates help to protect its inhabitants at a time of rising sea levels.

Mont St Michel, France. The sea was encroaching on this historic landmark, making access more difficult. That is, until a flood barrier was elected. Industeel supplied 36 tonnes of 2205 duplex plate as cladding for the gates’ coated carbon-steel frame. The valves were almost made from duplex grade 2205.

Victoriaslussen project, Stockholm, Sweden. This lock is located at Lake Mälaren right in the city centre, an area prone to floods. Apart from flood protection, the gates prevent brackish water from contaminating the drinking water. As part of the extensive Slussen project, new duplex sluice gates in duplex 2205 were built. They will be larger and stronger, capable of releasing more water than their wooden predecessors. The gates were inaugurated in 2022.

Kamihirai Flood Gate, Tokyo, Japan. This is a crucial structure in Tokyo’s flood defence system. Originally built in carbon steel in the 1970s, the carbon-steel slide gates were recently replaced with ones in duplex stainless steel. It was decided that using a conventional austenitic grade would significantly increase the weight and pose a risk to the structure. Therefore a lean grade, NSSC’s SUS323L, was used. Another factor that weighed in the selection of a strong material was the need for protection against earthquakes.

Public or private?

Should water be treated or distributed in the public or the private sector? When I was growing up in the UK the 1950s, water was free (or covered by local taxes) and unmetred, and it came from a publicly owned water authority. Then the water service was privatized, but the profit motive was held in check by EU legislation protecting the environment. When the UK left the EU, the water companies were free of this constraint, and sewage discharge increased to scandalous proportions as companies chose to please their shareholders rather than act in the public interest.

About this Featured Story

Appearing in the October 2024 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.