Welding technologies have evolved significantly over the past century, from simple manual processes to sophisticated automated systems. Precision and consistency are paramount in stainless steel welding, as even minor imperfections can compromise the finished product’s structural integrity and aesthetic quality.

Text by Ellie Gabel, Revolutionized

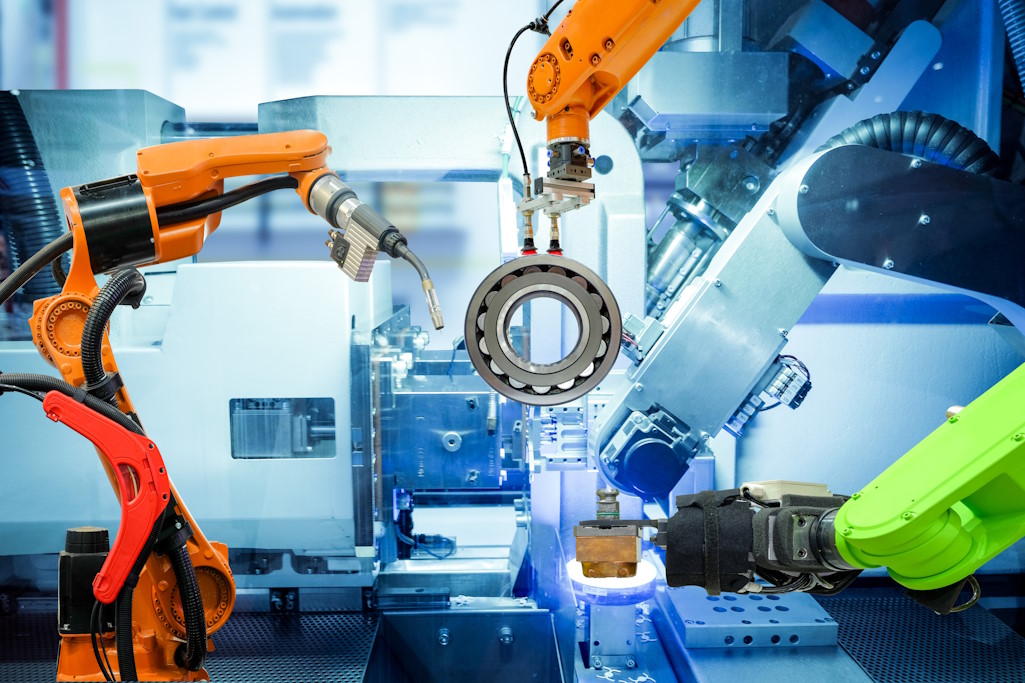

Robotics has increasingly become essential in the field of welding. It offers unparalleled accuracy and repeatability, which are crucial in maintaining high standards. Robots improve productivity and reduce the risk of human error by automating complex welding tasks. These factors make them an invaluable asset in modern stainless steel fabrication.

Advantages of robotics in stainless steel welding

Robotics has emerged as a powerful solution as the demand for higher quality and efficiency in stainless steel welding continues to grow. Automation can achieve precision, speed and safety that manual methods can’t match.

Precision and consistency – Robotics ensures uniform welds by executing precise, programmed movements that eliminate the variability inherent in manual welding. This consistency minimizes human error, defects and costly rework.

Additionally, robots can handle various welding tasks, from simple joints to complex geometries, making flexible automation a practical reality for stainless steel fabrication. This versatility streamlines production processes and contributes to substantial cost savings by maximizing efficiency and minimizing waste.

Efficiency and speed – Robotic systems excel at performing repetitive welding tasks with speed and precision far surpassing manual labor. Unlike human workers, robots can operate continuously without fatigue, maintaining a consistent pace that significantly boosts production throughput. This ability to sustain high-speed operations is especially valuable in industries with tight deadlines, where meeting production targets is critical. Integrating robotics into welding processes allows companies to accelerate their workflows and ensure large-scale projects are completed on time without compromising quality.

Enhanced safety – Robotic welding systems reduce human exposure to hazardous environments, a critical factor in enhancing workplace safety. In 2020, there were 48 fatal injuries involving welding, soldering and brazing workers in the US, underscoring the dangers associated with these tasks.

Automating the welding process lets robots take over operations that would otherwise expose workers to harmful fumes, extreme heat and sharp metal edges. This shift protects employees and contributes to a safer and more efficient work environment in stainless steel fabrication.

Robotic welding systems can enhance productivity, reduce labor costs and improve weld quality.

Advanced robotic welding techniques

As robotic welding technology advances, specialized techniques have emerged catering to the challenges of stainless steel fabrication. These cutting-edge methods offer enhanced precision and versatility, allowing more complex and high-quality welds in various applications.

- Automated TIG (GTAW) welding

In high-precision stainless steel welding, robotic systems deliver the meticulous accuracy needed to achieve clean, aesthetically pleasing welds. This level of precision is particularly crucial in industries where the visual quality of welds is as essential as their structural integrity, such as in medical equipment or food processing machinery. Ensuring consistent, flawless welds can enhance the appearance of the final product and improve its durability and performance. This capability makes robotic welding an indispensable tool for producing stainless steel components that meet the highest standards of quality and finish.

- Robotic MIG (GMAW) welding

Robotic MIG welding is efficient in high-speed, high-volume stainless steel fabrication. However, careful control is required to avoid over-penetration, which can result in too large and unsightly welds. Despite this challenge, robotic MIG welding remains a powerful tool for handling thicker materials and complex geometries. It delivers the speed and efficiency needed for large-scale production. Its ability to produce solid and reliable welds on various stainless steel configurations makes it ideal for industries demanding high throughput and precision.

- Laser welding integration

Combining robotics with laser technology takes precision welding to the next level, offering unmatched accuracy in stainless steel fabrication. This synergy allows clean and precise welds and is ideal for aerospace, medical device manufacturing and electronics industries. The focused laser beam — guided by robotic precision — ensures minimal heat distortion and produces robust and aesthetically pleasing welds. This advanced technique is indispensable for applications where the highest standards of cleanliness and precision are non-negotiable.

- Trends and innovations

Integrating predictive maintenance and real-time process optimization into robotic welding systems transforms how manufacturers maintain and enhance their operations. Leveraging advanced sensors and AI allows systems to anticipate equipment failures, minimizing downtime and ensuring continuous production. This proactive approach extends the robotic systems’ life span. It enhances the welds’ quality by constantly optimizing the welding parameters in real-time. As a result, manufacturers can achieve consistent, high-quality output while reducing maintenance costs and improving overall efficiency. Moreover, the rise of collaborative robots, or cobots, is also making waves in the welding industry, mainly because of their potential to work alongside human welders. Experts valued the cobot market at $1.2 trillion in 2023 and predict it could triple by 2030. Cobots are safe and intuitive and assist with complex welding tasks, enabling people to focus on more intricate tasks. Developing energy-efficient robotic welding systems is gaining traction as companies increasingly prioritize sustainability. These systems reduce energy consumption and lower operational costs. They contribute to a more sustainable and cost-effective welding process.

Challenges and considerations

The high costs associated with robotic welding systems — expected to exceed USD10,000 for industrial robots by 2025 according toe Statista — present a significant investment for manufacturers. However, the return on investment often justifies the expense. These systems can enhance productivity, reduce labor costs and improve weld quality.

Successful implementation and operation of these systems depend heavily on skilled workers and programmers who can manage and optimize the robotic processes. These factors further emphasize the need for specialized training and expertise within the workforce.

About the author

Ellie is a freelance writer who also works as an associate editor for Revolutionized.com. She specializes in covering the latest innovations in tech and science for an audience of industry professionals. When she’s not working on her next article, you can find her relaxing with her husband and their cat.

Shaping the future of stainless steel welding

As industry demands for higher efficiency, precision and safety grow, robotics are becoming increasingly integral to stainless steel welding operations. The future of robotic welding in this field promises greater advancements, with innovations enhancing quality, sustainability and production capabilities.

About this Featured Story

Appearing in the November 2024 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.