Succinic acid can be used to make a broad range of products found in everyday life, including polyurethanes, paints and coatings, adhesives, sealants, artificial leathers, food and flavor additives, cosmetics and personal care products, biodegradable plastics, nylons, industrial lubricants, phthalate-free plasticisers, dyes & pigments and pharmaceutical compounds. Many of us don’t know that when you cook your favorite dishes, the flavorings you use to enrich the taste often contain biosuccinic acid. In wine and soft drinks, succinic acid helps reduce acidity. As an ingredient in cosmetics and creams, it is a skin softener.

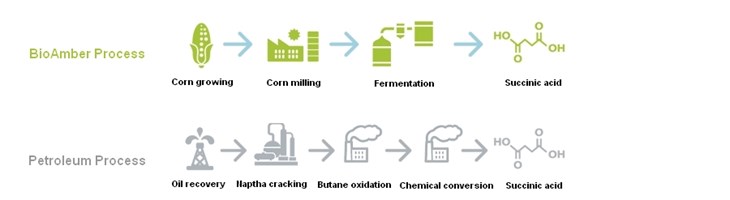

Historically, succinic acid has been made from fossil fuels. However, innovative green solutions have been developed by companies such as Myriant Corporation in the U.S., Reverdia V.O.F in the Netherlands (joint venture between Roquette and DSM), Succinity GmbH in Germany (joint venture of BASF and Corbion N.V), and BioAmber, with its head office in Montreal, Canada. These sustainable and proprietary industrial biotechnology processes, using fermentation to convert sugars into a succinic acid, are changing the industry worldwide.

BioAmber’s disruptive technology

BioAmber’s plant in Sarnia, Ontario, Canada, opened in late 2015, is the world’s largest bio-succinic acid production facility. The succinic acid is produced with sugars in renewable feedstocks, such as corn. It is indistinguishable from the petroleumderived chemical.

This disruptive technology not only produces succinic acid as a sustainable chemical, but also eliminates greenhouse gas (GHG) emissions and consumes much less energy than petroleum-based production. An independent life cycle analysis, which evaluated the entire production chain from the planting and harvesting of corn through to the purification of succinic acid, revealed that net GHG emissions for the entire process is zero. This compares to the 7.1 tonnes of GHG that are emitted per ton of succinic acid produced using the petroleum process.

At full capacity, BioAmber’s Sarnia facility will reduce GHG emissions by 210,000 tonnes per year, relative to the petroleum process. This is the equivalent of taking 45,000 cars off the road each year. The life cycle analysis also showed that the process uses 64% less electricity than conventional oilbased processes.

Disruptive technologies create new value, new markets and new operating parameters. Bayer Material Science has launched an innovative line of bio-based materials for textiles used in the footwear, sportswear, automotive and apparel industries. Replacing petrochemicals with BioAmber’s succinic acid means these eco-friendly products offer excellent performance and up to 65% renewable content.

Carbohydrates instead of hydrocarbons

When you compare fossil-fuel based organic chemicals to organic chemicals made from biomass, in other words, hydrocarbon-based chemicals to carbohydrate chemicals, the major difference is the oxygen content in carbohydrates. Fossil-fuel based organic chemicals are quite inert, non-reactive and their processing is not particularly corrosive. Therefore low alloy and carbon steel can often be suitable as materials for essential processing equipment. Bio-based chemicals on the other hand, which are water based, can be reactive, easily degrade and form compounds, such as acetic, formic and lactic acids, which are highly corrosive to low alloy and carbon steel.

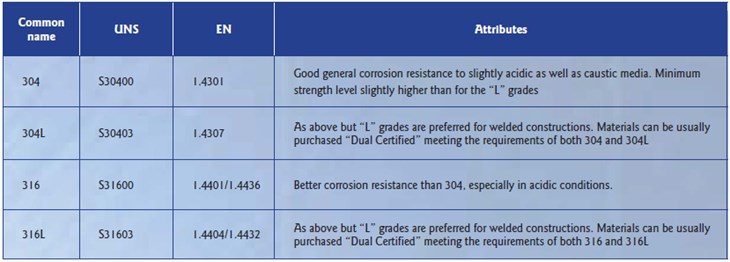

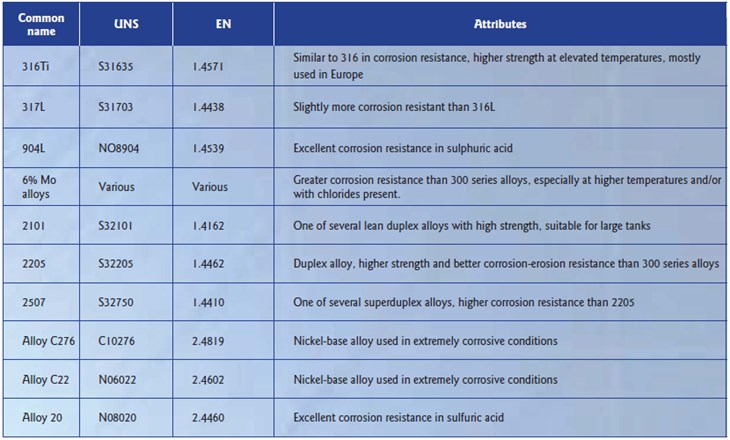

In biomass processing, the feedstocks, impurities, intermediates and by-products are all different compared to hydrocarbon processing. The majority of production equipment for bio-based organic chemicals must therefore be made from corrosion resistant materials. Nickel-containing austenitic (principally Types 304, 304L, 316 and 316L) and a range of nickel-containing specialty stainless steels, and at times also nickel-base alloys will be needed to ensure protection against corrosion. These nickel-containing materials are cost-effective and long lasting materials solutions for the growing bio-based chemicals industry.

Sustainability and alternate sources

While BioAmber is focused on using the most abundant low cost sugar available as feedstock, the company is very conscious of the need to be as sustainable as possible. Presently, this sugar comes from corn, however, sugar from cane, beets, sorghum, wheat and tapioca can also be used. BioAmber’s longer term goal is to move to agricultural waste, forestry and industrial waste as alternatives to traditional sugars. BioAmber’s plant in Canada is presently the world’s largest biosuccinic acid plant, with a production capacity of 35,000MT of succinic acid and 23,000MT of 1,4 butanediol (BDO).

To meet rapidly rising global demand for succinic acid and its derivatives, BioAmber intends to build additional plants in North America with a total cumulative capacity of 165,000 tonnes of succinic acid and 123,000 tonnes of BDO.

About the Nickel Institute

Nickel Institute is the global association of leading primary nickel producers. Its mission is to promote and support the use of nickel in appropriate applications. NI grows and supports markets for new and existing nickel applications including stainless steel; and promotes sound science, risk management, and socioeconomic benefit as the basis for public policy and regulation.

Through its science division NiPERA Inc., it also undertakes leading edge scientific research relevant to human health and the environment. NI is the centre of excellence for information on nickel and nickel-containing materials and has offices in Asia, Europe and North America.

www.nickelinstitute.org