Working in partnership with Ormskirk-based Additive Manufacturing Solutions Ltd and AMFG, Materials Processing Institute providing MES and workflow automation for manufacturing, the £600,000 SMART-APP project will enable high-level production of AM components, using Laser Powder Bed Fusion, through the introduction of smart predictive models for resource efficiency and waste reduction.

SMART-APP aims to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its lifespan with a minimal or an in-specification impact on product quality.

According to MPI, one area of particular interest is the growth of metal.

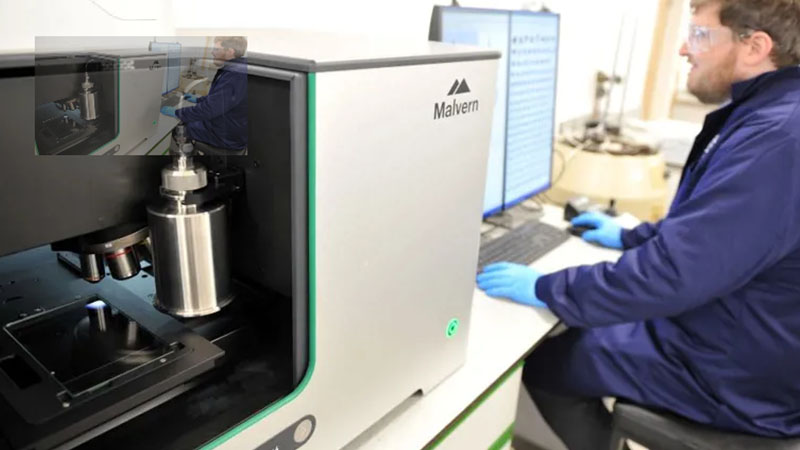

The research will feature advanced materials characterisation, and mechanical testing, investigating shelf life and the processability envelope of environmentally affected common stainless steel, titanium and superalloy base feedstock. It will also examine methods of reclaiming the powders and the effect on the final product.

The resulting outputs will be fed into an advanced database linking powder input properties against AM part performance to provide a predictive tool that will be available to industry.