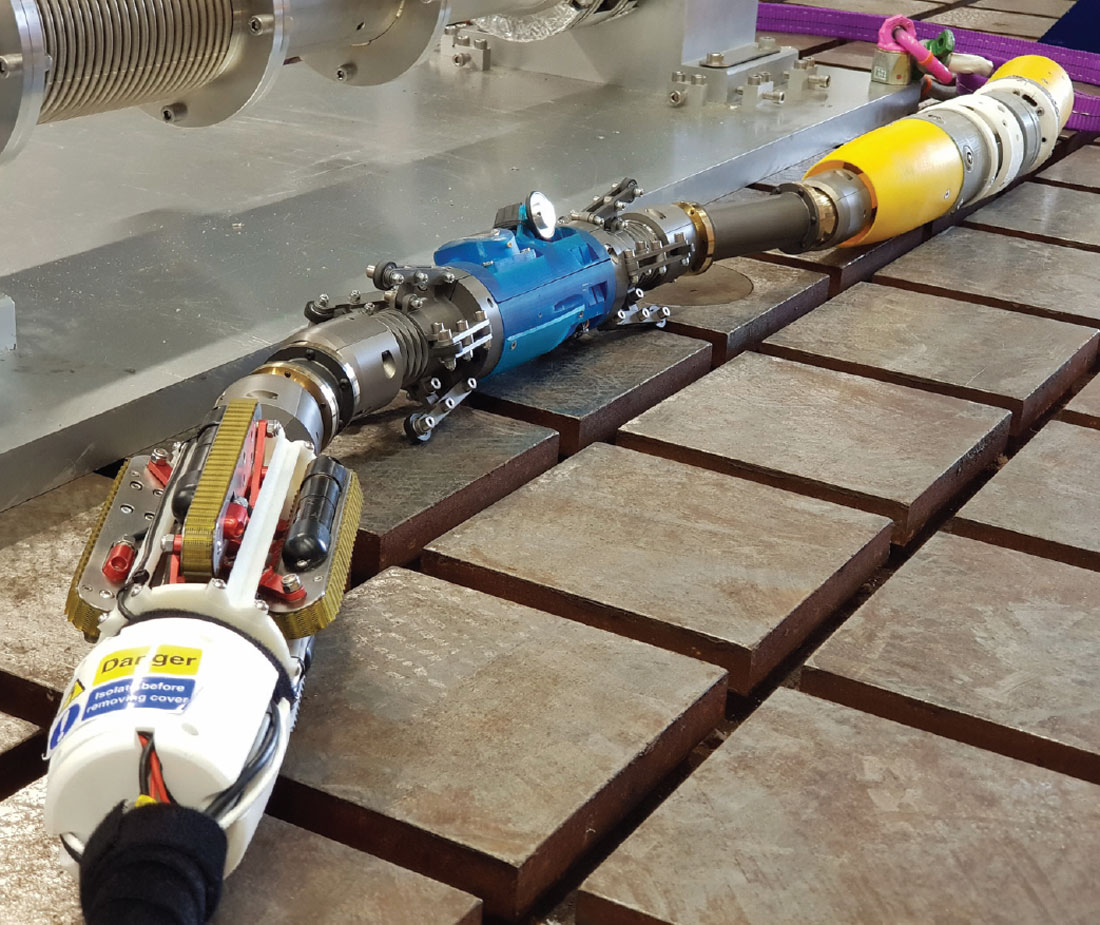

A ‘robotic snake’ has demonstrated its capability to operate inside fusion energy powerplant pipework, carrying out laser-welding in hard-to-reach locations.

Text & images by UK Atomic Energy Autority

A new laser-welding ‘robotic snake’ developed by the UK Atomic Energy Authority has demonstrated its capability to operate inside of fusion energy powerplant pipework and is now patented technology. The novel trials at Culham Science Centre are another step forward on the roadmap to delivering safe, sustainable, low-carbon fusion energy to the grid.

Next step in fusion

The GBP 2.7 million, seven-year project by UKAEA’s RACE (Remote Applications in Challenging Environments) was delivered as part of EUROfusion’s flagship DEMO programme, expected to be ITER’s successor.

The DEMO snake will be deployed and operated remotely inside a hazardous environment without being touched by humans. It can also work effectively in pipes packed together, with little space for access.

Tristan Tremethick, Lead Mechanical Design Engineer, UKAEA, said: “In fusion machines, pipework has to be connected and disconnected remotely because of the hazardous environment. Pipework in DEMO is extra challenging because of the limited working space. We’ve been looking at different ways of tackling this, and I’m delighted our new snake has passed its first set of trials.”

“The bespoke laser welding tool takes a novel approach and operates inside of the pipework to make the best use of the cramped space available. At RACE, we pride ourselves on providing complete solutions to enable operations and protect people in challenging environments, and this is another exciting result on our path to delivering fusion energy.”

Robotic maintenance

The project also involved creating an ultrasonic sensor-system to move the snake up and down the pipe to identify each precise working location. A separate launch system gets it inside the pipework remotely.

Tristan Tremethick added: “Ultrasonic sensors enable the snake to find the correct position, where it then clamps to the pipe and performs the weld from the inside. After the weld, the tool retracts and is removed from the pipe where it can be redeployed.”

“Robots are a key part of our mission to deliver low carbon fusion energy, and we need to become skilled in controlling machines like this one remotely. That’s because they will be used to maintain fusion energy power plants. We won’t be able to send people in, robots will keep them running – it’s the future.”

RACE has also developed a laser cutting tool operating on the same principles as the snake and both can potentially be used for other industry applications.

Fusion projects

EUROfusion consortium consists of experts, students and staff from across Europe collaborating to realise fusion energy, co-funded by the European Commission.

ITER is a fusion research mega-project in the south of France which will further demonstrate the scientific and technological feasibility of fusion energy.

For information:

www.gov.uk/government/news/robotic-snake-solves-fusion-energy-pipework-challenge