Nippon Yakin Kogyo’s flagship production facility in Kawasaki, Japan.

As Nippon Yakin Kogyo approaches its centenary in 2025, the company is powering ahead with strategies to decarbonise its business while further developing high-performance materials. It’s achieving this by manufacturing low-carbon products and supplying products to carbon-neutral industry sectors. As a special stainless steel manufacturer, the company provides nickel alloys to some of the world’s most demanding applications, utilising its many years of expertise combined with strategic planning and joint ventures. Stainless Steel World flew to the company headquarters in Tokyo to speak with the President, Mr Hisashi Kubota.

By Kiyo Ichikawa & Joanne McIntyre, Stainless Steel World

Founded in 1925, Nippon Yakin Kogyo (Nippon Yakin) is a Japanese special stainless steel manufacturer. The company manufactures and supplies strips and plates in various materials, from general-purpose stainless steel types 304 and 316L to high-performance materials like super stainless steel and nickel alloys. The company sells over 10,000 tons of nickel alloy flat products per year and, in recent years, has consistently ranked among the top three positions in the world.

Nippon Yakin’s developments in FY2022

Mr Kubota begins by summarising current market developments. “Demand for general stainless steel materials, which had been strong in the first half of the financial year, entered an adjustment phase in the second half. This contraction was due to excess stock on the market combined with a sluggish recovery in the automotive and other transport equipment sectors and a slowdown in the semiconductor sector.”

“In high-performance materials, the adjustment phase continued in the field of durable consumer materials – such as sheathed heaters for household appliances and bimetals – due to a decline in housing construction in the USA. However, the renewable energy field, such as solar power generation in China, has remained strong. Prices for raw materials, energy and electricity continued to rise, resulting in chronic cost increases.”

In response to this external environment, Nippon Yakin secured roll margin in response to rising raw material prices. Cost reductions were also implemented, resulting in a profit of 19.7 billion yen despite a 3.9% decline in sales volume compared to the previous year.

Medium-Term Plan 2023

“As we approach our 100th anniversary in 2025, we are intensely conscious of the need for flexibility and adaptability,” continues Mr Kubota. “This applies not only to our products but also to our raw materials. For example, we are developing carbon-neutral iron refining at the Oeyama Works and exploring how we can make use of so-called urban mines.” Nippon Yakin has launched its Medium-Term Business Plan 2023, a set of measures to be initiated and implemented over three years to achieve resilient and sustainable growth. The Plan outlines the company’s aim to contribute to the future of the earth as a leading supplier in the nickel alloy and stainless steel market by pursuing product and raw material diversification. Three strategies have been set:

- Developing and providing industrial materials that create new value by pursuing market needs;

- Enhance technological superiority and build a production system that responds to changes in the market environment;

- Establish a sustainable management foundation unaffected by external changes.

The main measures to achieve these three aims are:

- Expanding sales of high-performance materials to growth fields and target markets;

- Enhancement of material grades and sizes by deepening and expanding alliances centred on joint ventures in China;

- Manufacturing technology that realises a stable increase in the production of various high-performance materials;

- Securing superiority in future manufacturing technologies that contribute to carbon neutrality (carbonless, nickel smelting, etc.);

- Developing human capital, R&D, and capital investment plans from a medium- to long-term perspective.

Renewable energy sector

In the context of the carbon-neutral trend, demand for renewable energy sources such as solar photovoltaic (PV) and geothermal power is increasing. “PV power generation directly converts light energy into electricity using solar cells,” explains Mr Kubota. “The Siemens process is a typical method for producing polycrystalline silicon, the raw material for solar cells. It involves a process in which metallic silicon reacts with hydrogen and chlorine in a high temperature (approximately 500°C) and high-pressure environment. Highly heat-resistant Ni alloys NAS800H (UNS N08810) and NASH38X (UNS N08120) are ideal for this application, and sales of both alloys to China are strong.”

“Geothermal power generation is a system that generates electricity using steam extracted from a two-phase flow (hot water and steam) from volcanic regions deep underground. Depending on the corrosiveness of the flow, stainless steels such as type 304, duplex stainless steel, and super duplex stainless steel may be specified for highly corrosive two-phase flows.”

Japan’s Onikobe geothermal power plant started operation in April this year. The plant includes 110 tonnes of highly corrosion-resistant duplex stainless steel NAS64 (UNS S32506) welded steel pipes manufactured by Nippon Yakin Group’s subsidiary NAS TOA for the two-phase flow pipes. “Although the geothermal environments in which highly corrosion-resistant duplex stainless steel are applied are limited, there are examples both in Japan and overseas, and we will continue our efforts to capture demand,” continues Mr Kubota.

Hydrogen energy sector

Globally, hydrogen is attracting attention as an energy source for decarbonisation, and initiatives for the hydrogen value chain (hydrogen production – transport – storage – use and consumption) are underway. One field where the practical application and commercialisation of hydrogen are rapidly progressing is fuel cell vehicles, which require high-performance materials. Hydrogen refuelling stations have highly pressurised hydrogen gas environments and are at high risk of hydrogen embrittlement. Therefore, an improved type 316L, which has improved resistance to hydrogen embrittlement through the optimising of composition, is used.

In 2017, heat exchangers using Nippon Yakin’s improved Type 316L won the worldstainless (previously known as ISSF) Best New Applications Featuring New Technology Silver Award, and the Japan Stainless Steel Association’s 16th Annual Stainless Steel Association Award for Best Application. Various technological developments are progressing in the hydrogen-related field, which has a high potential for further new applications and demand in the future.

“Our Solution Sales Department is taking the lead in identifying industry and technological trends, gathering information to identify future needs. In addition, under the Medium-Term Business Plan 2023, a new materials evaluation test laboratory for hydrogen environments is planned for completion in 2024. This test laboratory is expected to contribute to the accelerated application and adoption of existing mater ials and the development of new materials in the hydrogen environment field.”

High-performance materials for everyday life

Nippon Yakin’s high-performance materials are ideal for drinking water reservoirs, temperature regulators (thermostats) for household products and sheath heaters, supporting our daily lives.

Water reservoirs: Before distribution, drinking water is stored in reservoirs made of concrete, carbon steel, FRP and stainless steel. However, stainless steel is increasingly popular for this application due to its earthquake resistance, durability and maintenance-free properties. While general-purpose austenitics such as types 304 and 316 are common for items such as pipes, the gas-phase part of the reservoir (above the gas-liquid boundary) is a severely corrosive environment due to the concentration of chlorine gas for sterilisation, which causes problems with type 304 and type 316. Therefore, the more corrosion-resistant duplex stainless steel NAS 64 (UNS S32506) is used. Types 304, 316 and 444 are specified in the liquid phase section. In some cases, stainless steel linings are used to improve existing water distribution reserviors, and NAS64 (UNS S32506) is used in the gas phase section.

Household thermostats and sheathed heaters: Everyday items such as coffee makers and toasters have built-in temperature thermostats that utilise bimetals. Bimetals combine materials with high and low coefficients of thermal expansion. As the temperature rises, the material with the higher coefficient expands, causing it to curve. Thermostats utilise this feature of bimetals to switch on and off automatically in response to temperature changes. NAS36 (Fe-36%Ni alloy) has a low coefficient of thermal expansion, while NAS206Mn (Fe-20%Ni-6%Mn alloy) and NAS22-3 (Fe-22%Ni-3%Cr alloy) have high coefficients of thermal expansion.

Sheathed heaters used in electric water heaters, coffee makers, cooking heaters and air conditioners have a structure in which a heating element such as nichrome wire is placed in a metal pipe (sheath) and insulating powder is filled between the heating element and the sheath. The most commonly used sheath materials are NAS 800 (alloy 800), NAS H840 (alloy 840) and NAS 825 (alloy 825) due to their heat and corrosion resistance. Sheath heaters use electrical energy for heating, which contributes to reducing CO2 emissions in households.

Floor steel POLKA PLATE®

Nippon Yakin also supplies high-value-added stainless steel as an attractive product, with a good example being the POLKA PLATE®, a type 304 stainless steel sheet for floors with a convex polka-dot pattern. Its excellent anti-slip properties earned it the highest rating of R13 in the German industrial standard anti-slip test (DIN 51130). Compared with checker plate (ordinary striped stainless steel sheet), the rounded polka dots prevent debris and water from sticking, providing excellent cleaning and drainage properties.

The product is particularly popular for use on factory floors and stairs in the food, chemical, and pharmaceutical fields, where it is highly valued for its non-slip properties and ease of cleaning. In 2022, over 130 tonnes of Polka Plates® were used in the cosmetics sector alone. POLKA PLATE® cust omers are often repeat users due to its excellent properties and visual appeal. To increase awareness of the product’s appeal, Nippon Yakin presents a video on its website showing a cleaning test comparing POLKA PLATE® and Checker Plate and a video introducing installation examples, including users’ impressions.

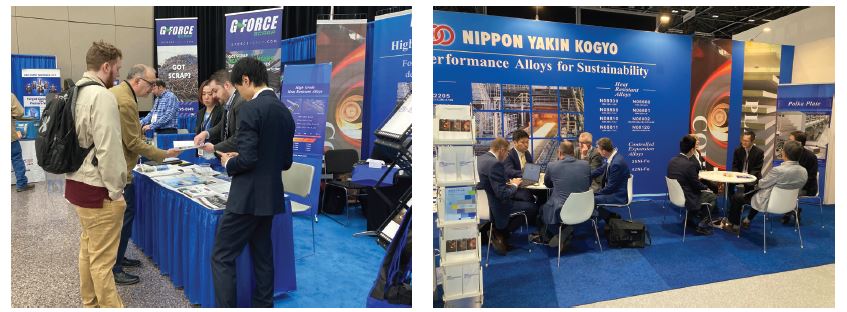

Resumption of exhibition activities

Nippon Yakin engages in overseas exhibitions to raise its profile, develop new customers and strengthen relationships with existing customers. Post-pandemic, they resumed activities starting with Heat Exchanger World Americas 2022, held in Houston, USA. “Focusing on Nippon Yakin America, Inc. (Nippon Yakin’s US subsidiary), we met many new and existing customers. It was great to experience how effective face-to-face conversations are again,” smiled Mr Kubota.

At Stainless Steel World 2023 in September, held in Maastricht, the Netherlands, Nippon Yakin’s booth was run mainly by staff from Nippon Yakin Europe Limited (Nippon Yakin’s UK subsidiary). “We took the opportunity to visit customers from Europe, Asia and North America, both for business meetings and technical meetings. We achieved good results in developing new customers.”

Ni alloy products through China JV

Nippon Yakin is expanding sales of high-performance material plates for the Chinese market and is also working to develop product items through a Chinese joint venture. In 2020, 3270 mm wide sheets of highly heat-resistant Ni alloy NAS800T (UNS N08811) were manufactured using the wide-width hot rolling mill of Nanjing Iron and Steel Co., Ltd., which has a cooperative relationship with the company through its joint venture Nisco Nippon Yakin Kogyo Nanjing Co., Ltd.

“In 2021, we successfully manufactured 3510mm wide plates of highly corrosion-resistant and heat-resistant Ni alloy NAS625 (UNS N06625),” explains Mr Kubota. “In May this year, we manufactured 3900 mm wide plates of highly corrosion-resistant Ni alloy NAS NW276 (UNS N10276).”

“Highly heat-resistant, corrosion-resistant Ni alloys have a high-temperature strength, which normally makes it difficult to manufacture in wide product forms. However, we achieved this by utilising Nippon Yakin’s know-how and the Nanjing Iron & Steel facilities. Widening the plate material reduces the welds required during equipment manufacturing, contributing to lower construction costs and shorter delivery times. We will continue commercialising wide plates for other alloys and improving our competitiveness.”

To one hundred years and beyond…

In summary, Mr Kubota says: “Nippon Yakin is expanding its high-performance materials business, which is a growing field. At the same time, we are striving to be a sustainable company as we approach our 100th anniversary in 2025 and beyond. We aim to continue to earn the trust of our customers through our high-quality products and services.”

Expanding sales of high-performance materials

Nippon Yakin has an extensive range of high-performance materials, including corrosion-resistant, heat-resistant and thermal expansion control materials. These materials are utilised in various applications, which benefit from the unique characteristics of each material. The company is developing and capturing demand for high-performance materials through a solution-based sales strategy.

Facts & Figures

Name:

Founded:

Employees:

Headquarters:

Office outside Japan:

Products:

Website:

Materials:

Facts & Figures

Nippon Yakin Kogyo Co., Ltd.

1925

1,156

Tokyo, Japan

London, Chicago, Singapore, Shanghai, Nanjing

Plates, sheets and coils

Stainless steels, super stainless steels, nickel alloys and iron-nickel alloys

About this Featured Story

This Featured Story appeared in Stainless Steel World November 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.