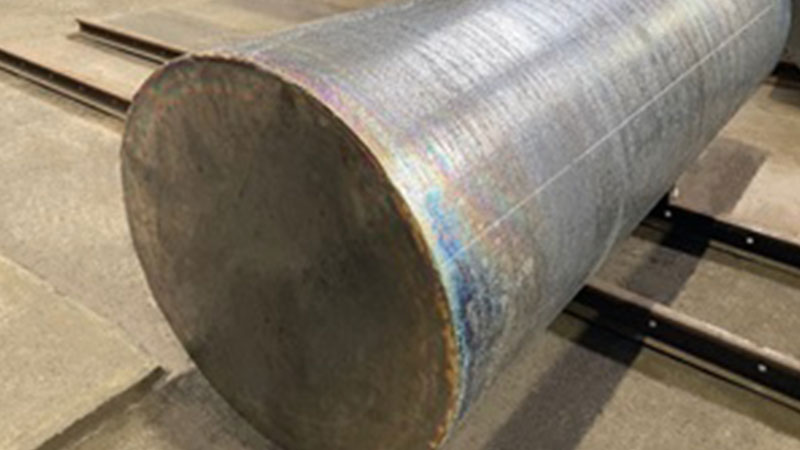

Nippon Steel Corporation (Nippon Steel) has developed the world’s first Eco-friendly Commercially Pure Titanium, TranTixxii™-Eco, and has started supplying it to Snow Peak. Titanium is a metal that helps achieve carbon neutrality because it is highly resistant to corrosion and durable enough for long-term use. Nippon Steel has developed TranTixxii™-Eco. TranTixxii™-Eco is an Eco-friendly material that helps reduce CO2 emissions and save resources with titanium ingot made of over 50% scrap titanium. It will be manufactured at the East Nippon Works, Naoetsu Area. Commercially Pure titanium needs to be made with great care to ensure an extremely high degree of purity. To address this challenge, it uses a new model electron-beam melting furnace (the EB furnace) at Nippon Steel Naoetsu Titanium Co., LTD. For the EB furnace, Nippon Steel has created an optimal combination of scrap arrangement and electron-beam irradiation patterns in the melting process by applying technology cultivated in-house for ordinary steel. This has enabled us to homogenize ingot components to produce high-quality products. However, for TranTixxii™-Eco, it has substituted over 50% of the raw materials with recycled scrap. This helps reduce CO2 emissions from the smelting process by more than 50%.