Today, the Texas facility employs approximately 120 people and plays a key role in supporting the semiconductor industry’s evolving supply chain.

Maruichi Stainless Tube Co. specialises in the manufacture of high-performance stainless steel pipes, tubes, and coil tubes for demanding industrial applications. With a strategic roadmap in place for 2030, the company is intensifying its focus on decarbonisation – both within its manufacturing processes and through the development of advanced tubing solutions tailored for hydrogen and other low-carbon energy systems. Key investments such as the commissioning of a 5,000-ton press and the expansion of production capabilities are positioning Maruichi for continued growth and innovation in the global marketplace.

By Kiyo Ichikawa & Joanne McIntyre, Stainless Steel World

Maruichi Stainless Tube continues to demonstrate robust performance in the global market, with notable increases in both sales and profitability over the past financial year. During our interview, Company President Mr Takashi Onishi began with a summary of the company’s achievements over the past twelve months. “Despite ongoing market challenges, Maruichi Stainless Tube delivered a solid performance in 2023, recording sales of YEN 27.7 billion (approximately EUR 172 million) and an operating profit of YEN 3.8 billion (EUR 23.6 million),” Mr Onishi shared. “This reflects an improved return on sales of 13.7%, underscoring the strength of our operational strategy and the continued trust of our global customer base.”

Family day at the Maruichi plant in Texas.

Expansion into Alloy 825 & duplex coil tubes

Maruichi Stainless Tube entered the coil tubing market in 2020, with exports starting in 2021, primarily targeting applications in the oil & gas and petrochemical sectors. “Since 2021, we have maintained a steady flow of orders from national oil companies in the Middle East,” notes Mr Onishi. “Notably, in 2023–2024, we secured a major order totalling 390,000 metres of coil tubing for a large-scale project.”

Driven by rising resource prices and renewed capital investment in energy infrastructure, demand for coil tubing has rebounded strongly, contributing to year-on-year growth in sales volume. To meet stringent customer specifications, Maruichi has invested in advanced testing and inspection facilities, ensuring product performance and compliance with industry standards.

“Although we are a relatively new player in the coil tubing market, we are positioning ourselves for strategic growth across Asia by focusing on high-value, technically demanding materials such as high-nickel Alloy 825 and duplex stainless steels,” Mr Onishi adds. “These materials require advanced processing capabilities, and we are committed to delivering the precision and reliability our customers expect.”

Strategic integration into Maruichi Steel Tube Group

Formerly known as Kobelco Steel Tube Co., the company joined the Maruichi Steel Tube Group in April 2020 and was rebranded as Maruichi Stainless Tube Co. Despite the transition occurring during the COVID-19 pandemic, customer alignment with the new brand was swift, solidifying the company’s position in the global stainless steel tubing market.

As a leading producer of carbon steel pipes, Maruichi Steel Tube Group operates 11 domestic plants in Japan and 19 facilities across the U.S., Mexico, and Asia. Its diverse product portfolio includes structural tubing, automotive and motorcycle components, greenhouse piping, and electrical conduits. Maruichi Stainless Tube Co. now leverages this global footprint to gain expanded market access, supply chain efficiency, and technical synergies across the Group

BA pipes for semiconductor & automotive demand

Maruichi Stainless Tube currently manufactures approximately 150,000 bright annealed (BA) pipes per month. The company anticipates a market rebound in the near term, driven by renewed demand from the semiconductor and automotive sectors. “While there has been a temporary market slowdown – partly due to geopolitical factors such as the US administration transition and ongoing trade tensions between the US and China – we expect a recovery between 2025 and 2026, supported by the rollout of government subsidies,” says company President Mr Onishi.

Although semiconductor-related demand is presently stable, it is projected to recover further in the second half of 2025. Maruichi’s manufacturing and quality assurance systems are highly regarded both domestically and internationally, underpinning ongoing orders from key regions, including North America, South Korea, and Japan, where large-scale semiconductor fabrication plant construction is underway.

The semiconductor sector is a key strategic growth area for the Maruichi Group. “For many years, we have supplied clean pipes and EP mother pipes to semiconductor manufacturing facilities, establishing long-standing, trusted relationships with our users—one of our core strengths,” continues Mr Onishi. “In recent years, we have expanded both our production capacity and product size range. Looking ahead, we will leverage these deep customer relationships to swiftly respond to the growing demand for high-quality gas piping in semiconductor fabrication. By aligning our development, manufacturing, and sales teams—and working closely with our users—we aim to play an active role in reinforcing the semiconductor supply chain.”

As global demand for semiconductors continues to surge, the need for bright annealed (BA) tubes—critical components in semiconductor manufacturing equipment—is growing rapidly. In response, Maruichi Stainless Tube is expanding its domestic production capacity to 250,000 tubes per month through significant capital investments.

BA pipes made in the USA

To further support demand in the United States, where numerous large-scale semiconductor fabrication plants are under development, Maruichi established Maruichi Stainless Tube Texas Corporation in 2022. Leveraging its extensive business experience in the U.S. market and advanced manufacturing capabilities, the company delivers high-quality products and responsive service tailored to customer requirements. Today, the Texas facility employs approximately 120 people and plays a key role in supporting the semiconductor industry’s evolving supply chain.

Looking ahead, demand for bright annealed tubing is also expected to remain strong in the automotive sector, the second-largest application area for this product after semiconductors.

“We anticipate a gradual shift in demand for our fuel rail piping – used in direct injection engines – toward electric and hydrogen-powered alternatives such as battery electric vehicles (EVs) and fuel cell vehicles (FCVs),” notes Mr Onishi. “However, while EV and FCV adoption is increasing, a sudden decline in internal combustion engine vehicle production, including hybrids, is unlikely in the near term.”

Investment plans to 2030

As part of its long-term vision for 2030, the Maruichi Steel Tube Group has launched its “Stainless Steel Project,” a forward-looking initiative aimed at capturing growth opportunities

in the semiconductor sector and supporting the global push toward decarbonisation. Central to this plan is a record capital investment of YEN 48 billion (approximately EUR 300 million) to construct two new manufacturing facilities in Shimonoseki, Yamaguchi Prefecture – marking the largest single investment in the Group’s history.

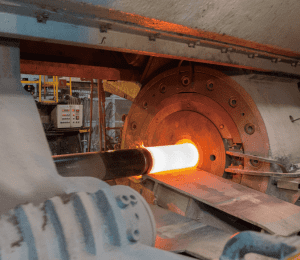

Welded pipe facility – A new welded pipe plant, covering 24,000 m², is being constructed adjacent to the Maruichi Stainless Tube head office site. Groundbreaking took place in May 2025, with commercial-scale production targeted for the 2027 fiscal year. Once operational, the facility will deliver a monthly output of 1,500 tons, primarily serving the domestic Japanese market. Seamless pipe facility – To significantly boost seamless pipe production, a second factory – 18,000 m² in size – will be built within the same head office grounds. This facility will feature the installation of a 5,000-ton hot extrusion press, complementing the existing 2,000-ton press. The upgrade will increase monthly seamless pipe capacity to 2,000 tons and expand the maximum outer diameter of pipes from 6 inches to 10 inches. Mass production is scheduled to begin in the latter half of 2027, with target markets including Japan, the US, Asia, and the Middle East. Commenting on the rationale behind this investment, Mr Onishi explained: “With the expected expansion of the hydrogen supply chain – including infrastructure such as hydrogen refuelling stations and cryogenic tankers – demand for high-performance stainless steel pipe is forecast to rise. Our increased tube diameter capability is a direct response to this trend, supporting applications that require large-diameter tubing for hydrogen transport and storage.”

“In parallel, the new 5,000-ton press will enhance our ability to process high-nickel alloys such as Alloy 625 and Hastelloy C-276, both of which are critical in environments demanding superior corrosion resistance and mechanical strength. These materials will be essential in meeting the next generation of technical requirements across hydrogen, chemical processing, and advanced energy systems.”

Sustainability Development Goals

A key objective of the Maruichi Steel Tube Group in support of a decarbonised society is the substantial reduction of CO2 emissions across its operations. In alignment with national climate targets, the Group has committed to a 46% reduction in CO2 emissions by 2030, relative to 2013 levels.

“As the stainless steel division operates the largest number of heat treatment facilities within the Group, it also accounts for a significant share of our emissions,” explains Mr Onishi. “This places us in a leadership position to drive emission reduction efforts.”

In 2022, the company completed an upgrade to one of its stainless steel tube heat-treatment furnaces, achieving a 10% reduction in fuel consumption. Further, solar panel installation on the office building roof contribute to the transition toward renewable energy sources.

“Our initial focus is on reducing Scope 1 emissions – those directly generated by our operations,” Mr Onishi adds. “However, our approach is holistic. We are also preparing to address Scope 2 emissions from purchased electricity and utilities. By pursuing incremental improvements across all areas of the business, we are embracing a ‘no sanctuary’ mindset – where no opportunity for emission reduction is overlooked.”

Advancing toward a decarbonised society

Maruichi Stainless Tube is actively contributing to the advancement of a decarbonised society through its long-standing involvement in hydrogen infrastructure. For many years, the company has been manufacturing high-pressure stainless steel piping for use in hydrogen refuelling stations.

In these stations, hydrogen is either delivered from external sources or generated on-site. It is then pressurised via a compressor, stored in high-pressure accumulators, and dispensed to fuel cell vehicles through a high-pressure delivery system. The piping that connects the compressor, storage vessels and dispenser must be engineered to withstand the demanding conditions of a high-pressure hydrogen environment.

To meet these requirements, Maruichi produces cold-worked, high-strength 316 series stainless steel tubing.

These pipes are specifically designed for applications requiring superior mechanical strength, tight dimensional tolerances, and high resistance to hydrogen embrittlement. The company adheres to strict quality and safety standards to ensure performance and reliability in these critical systems. Through consistent delivery of high-specification piping, Maruichi Stainless Tube has established a strong track record in the Japanese market and continues to support the development of hydrogen infrastructure—helping to lay the foundation for a low-carbon energy future.

KRSA A31 – enhancing efficiency of petrol vehicles

“Decarbonisation remains a central theme in our research and development activities,” explains Mr Onishi. “While the adoption of zero-emission vehicles – such as fuel cell vehicles (FCVs) and battery electric vehicles (EVs) – is expected to accelerate, internal combustion engine vehicles, particularly petrol-powered models, will continue to play a significant role in the near term. Therefore, improving the environmental performance of petrol vehicles is a critical step toward achieving a low-carbon society.”

To address this, Maruichi Stainless Tube has developed KRSA A31, a new high-strength stainless steel alloy engineered specifically for fuel rail piping in direct injection gasoline engines. This advanced material, first detailed in Stainless Steel World Americas (August 2021), enables higher injection pressures, which improve combustion efficiency and reduce emissions. Additionally, the superior strength of KRSA A31 allows for thinner-walled tubing, contributing to overall vehicle weight reduction and enhanced fuel economy. The material also supports greater efficiency in component manufacturing due to its improved formability and reduced material usage. “Of course, we are also looking ahead to the future and new demand for stainless steel pipes in new energy fields such as hydrogen and ammonia. R&D projects are underway from the perspective of producing, transporting/storing and using hydrogen, aiming for a hydrogen society. As gaseous hydrogen embrittles steel, and liquid hydrogen has an extremely low temperature of -253°C, materials must be selected carefully. Ammonia can also corrode steel materials depending on the usage environment, so materials used in infrastructure must be carefully selected. We believe stainless steel is one of the leading candidates for solving these problems.”

“Looking ahead, we will continue to expand our R&D initiatives to support global decarbonization efforts,” Mr. Onishi concludes. “Our aim is to advance and apply our high-pressure hydrogen piping and high-strength material technologies, driving innovation across both conventional and next-generation mobility platforms.”

“The 5,000-ton press represents a cornerstone of our commitment to building a robust hydrogen supply chain. With this capability, we will enhance our ability to meet the growing demand for stainless steel pipes in emerging energy sectors such as hydrogen and ammonia, thereby contributing meaningfully to the transition toward a low-carbon future.”

About this Featured Story

Appearing in the June 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.