The past two years have been challenging for many companies, including the team at Mannesmann Stainless Tubes. However, the management seized the opportunity to restructure their organisation and strategy, implementing forward-thinking changes to prepare the global business for future challenges such as decarbonisation and the energy transition. We spoke to Tobias Wetzel and Christophe Le Rigoleur (Managing Directors), Patrik Schraven (General Manager Marketing and Business Development), Brian Mercer (Product Development) and Vitali Zeis (Sales Director) about the changes.

By Joanne McIntyre, Stainless Steel World

Sitting around the table with the Mannesmann Stainless Tubes team, Managing Director Christophe Le Rigoleur wanted to start with a particular message. “We want to convey our heartfelt thanks to our employees, wherever they may be around the world, for getting us through the Covid crises with such professionalism. From Europe to the US to Asia, our teams kept the company on track to serve customers without interruption. This was particularly challenging at our production plant in Bergamo, Italy, one of the hardest-hit regions in all of Europe. From the entire management team, we extend our thanks.”

Management reorganisation

When the Covid pandemic hit Europe in 2020, severely disrupting global business and travel, the MST team quickly decided to implement a comprehensive management restructuring originally scheduled for the following year.

Mr. Le Rigoleur explains: “Our team reviewed the organisation and structure of the company to develop the comprehensive MST 2025 strategy and were able to incorporate changes caused by Covid into our working practices and business structure. On the management team, changes include the appointment of Tobias Wetzel as Managing Director; the reinforcement of marketing activities by appointing Patrik Schraven as Head of Marketing; and the appointment of Brian Mercer as Head of Product Development.

Vitali Zeis was appointed global Sales Director, except for North America. Eduardo Gomez was appointed the President of MST USA, reinforcing both the production and business part of the company in the US/Canada/Mexico region. These changes ensure we are ready for tomorrow’s challenges.”

Patrik Schraven adds: “Over the past year, we carried out a deep market analysis of strategic market segments (SMS) to understand our customer’s needs and develop solutions for topics as diverse as material selection, tube design, logistics, etc. Each market segment was analysed in depth from the aspect of the customer application.”

World and market changes

The past two years have brought seismic changes to the market, explains Mr. Le Rigoleur. “These included a sudden oil crisis resulting in a period of negative prices, and severe disruptions to the aerospace industry, which has only recently started to recover. Furthermore, the global movement towards decarbonisation has strongly impacted our strategy.”

Mr. Wetzel continues: “MST is actively supporting the energy transition and the move to a decarbonised society. Many of the industries in which we are active are strongly affected. Our focus is on developing product solutions to support the transition and the evolving market. As part of the Salzgitter Group, we embrace that our shareholders have strongly committed to circularity in the industry. While this might be challenging, we believe there is no other choice. Society and our customers are all facing this change, and we will fully support them.”

MST believes the push for decarbonisation will lead to demanding applications requiring more stainless steel and nickel alloy tubes and pipes. “The demand for seamless tubes in high-end alloys will rise because there are simply no alternatives given the tough conditions of the end-users operations”, explains Mr. Wetzel. “As a leading seamless tube manufacturer, we face tremendous pressure and responsibility to develop products that can resist ever-increasing and -decreasing temperatures, (e.g. H²), higher pressures, and corrosive environments. While we will continue to serve our existing markets, our new focus is developing new solutions to project ourselves into the future. To some extent, we are taking a leap of faith to develop what we believe evolving markets will need.”

Evolution of new & existing technologies

“As the world moves towards decarbonisation, it’s also vital to improve the efficiency of existing technologies,” explains Mr. Mercer. “Our role is to develop seamless tubes and pipes for technologies substantially reducing or eliminating CO2 emission, ranging from ultra-super-critical coal-fired plants, carbon capture technologies, to waste-to-energy and solar power plants, to finally supporting the evolution in the nuclear and fusion industry. We must remember that improving all forms of energy are necessary to help us move towards a low to zero carbon society.” Mr. Schraven adds: “There are many new and evolving technologies where we play an increasingly important role. For example, business units within the Mannesmann group are involved in hydrogen transportation, utilising our seamless tubes. Stainless steels and nickel alloys provide perfect solutions for electric car engines, which require non-magnetic components.”

“As the world population increases, so does the fertiliser industry. Together with our partners, we are developing new material solutions to produce phosphoric acid, replacing traditional graphite tubes with high-end alloys for greater efficiencies.”

New Managing Director

In November 2020, Tobias Wetzel was appointed Managing Director of Mannesmann Stainless Tubes at the company headquarter in Mu˝ lheim a.d. Ruhr, Germany, alongside Christophe Le Rigoleur. His appointment is the culmination of a long career at Mannesmann dating back to 2001. Mr. Wetzel has fulfilled several positions within the company, both in Germany and in the company’s manufacturing plant in Houston. This experience has given him a thorough understanding of the company’s capabilities and expertise and the linkages between the various companies in the organisation.

Developing staff competencies

To meet the demands of the evolving global market, MST has committed to raising the staff skills of its personnel to an even higher level. Mr. Le Rigoleur: “We provide continuous training to adapt our teams to future markets. The company has engaged in both internal and external training programs. Our research partners at SZMF (Salzgitter Mannesmann Forschung GmbH) have developed programs focusing on technical competencies in close cooperation with universities. Internal classes go far beyond pure metallurgical knowledge to include IT, digitalisation, and compliance training. Ongoing cultural training ensures fair competition and fair trade in the future to maintain our leadership position in the market.” Mr. Zeis adds: “Sales teams receive coaching to learn how to listen to customers and ask the right questions. They have the skills to delve deeply into technical issues and understand what customers expect. The world is changing, and today we need to be involved with the customers of our customers, such as design institutes and end-users, to offer competitive products.”

Premium products segment

The MST team has observed that decarbonisation is driving many technical challenges in its premium product market segment. “This evolution presents many challenges to the industry in general, not just the seamless stainless steel tube and pipe sector”, explains Mr. Le Rigoleur. “We support our customers to achieve this in demanding applications for industries as diverse as oil and gas to power generation, aerospace, Carbon Capture Storage (CCS), etc., strengthening our position in this premium end-user market segment while supporting the industry.” The MST team is utilising the vast expertise of the R&D institute SZMF. Patrik Schraven explains: “Collaborative projects with SZMF are underway for sectors ranging from solar power to fertilizers. Under our new structure, the marketing department now combines traditional marketing, business development and R&D. All three activities are united in one business unit, with the bulk of the research work carried out at SZMF.

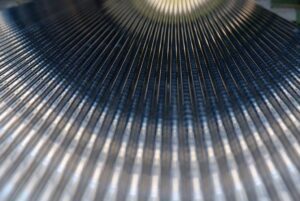

The strategic market segment includes key sectors such as oil and gas, power generation, and renewable energies. The team is developing green energy applications, particularly for its use in the production of e-fuel, which we see as an emerging future trend, especially for the aerospace industry.” MST has invested heavily in the technology required to develop products for the future, including the recent acquisition and commissioning of the world’s largest cold pilger mill at its Remscheid (Germany) plant. “This massive machine, and the various equipment connected to it, gives us tremendous advantages for some specific applications, as well as allowing us to make larger diameter coldfinished products,” explains Mr. Wetzel.

Commodity products strongly supported

The MST management team is acutely aware of the importance of distributors in the commodity product market. “Distribution plays a vital role in achieving a highly organised and structured market,” explains Mr. Zeis. “We collaborate fully with distributors, ensuring they have a stable inventory. A full review of our distributor strategy has highlighted areas to offer better service, improved availability and faster reactivity. Supporting our distributors is of key importance.”

A timeless brand

Mannesmann ranks among the most prominent brands in Germany’s industrial history, featuring as one of the Brands of the Century in Florian Langenscheidt’s book of the same name. “This demonstrates we have a very solid background of excellence on which we can develop our ambitious future.

We are very proud of the Mannesmann brand, and the logo represents a commitment to the integrity we have today,” smiles Mr. Wetzel.

“The Mannesmann brothers invented seamless tubes at our plant in Remscheid; today, that site is home to the largest, most modern cold pilgering machine in the world accomplished by straightening technology operated by artificial intelligence with learning competence. This demonstrates how MST has continuously driven the industry forward. Tubing technology may be mature, but we continue to push the limits of our technological capabilities.”

Sharing competencies

The MST team makes the final point is that while some aspects of the restructuring may be less visible, they will have a big impact on their customers. “We now share competencies with the Salzgitter group in administrative areas such as financial processes, which delivers a much higher level of expertise”, explains Mr. Wetzel. “We’re upgrading our entire IT infrastructure, and by sharing competencies and standardising processes, we gain the efficiency needed in today’s world. It will also drive ahead digitalisation, for example connecting customers with interfaces and facilitating e-business. We will update production scheduling to optimise capacities, identifying availability and bottlenecks. We will share and utilise the resources of the entire group, such as quality management and maintenance management. Ultimately this will help us to serve our customers and their markets better. Whatever the future may bring, we are ready.”

Salzgitter AG to 2030

In February, the Salzgitter Group outlined its strategy up to 2030. CEO Mr. Gunnar Groebler stated: “Society’s determination to achieve climate neutrality is our motivation to rapidly reorganise the company with a focus on circularity and the principle of resource-conserving closed loops of energy and materials with a low CO2 footprint.” The company is taking a holistic view of processes and product developments, combining them intelligently at an early stage when products are designed, together with customers.

Burkhard Becker, Member of the Executive Board, stated: “For 130 years, the Mannesmann brand has been synonymous with the highest quality pipes and tubes. Our pipes and tubes business is very well positioned with an extensive range of applications, from large-diameter pipes right through to stainless steel special tubes, with plants in Europe and North America. [We are] maintaining and expanding the line pipe infrastructure for natural gas as a bridging technology and hydrogen as a future source of energy. The Mannesmann brand will continue to stand for the development of successful solutions for the Energiewende’s (energy transition) infrastructure and mobility in the future”.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.