Lincoln Electric® officially announced its new Process HDT solution for the heavy fabrication industry. Developed for high-deposition robotic applications, this new innovative solution doubles the deposition rates typically seen in single-wire processes. By combining a new high-deposition waveform with a specially formulated metal-cored wire, Process HDT delivers deposition rates that exceed Tandem MIG applications, but with the streamlined set-up of a single-wire application.

Utilizing the Power Wave® S700 Power Source, Metalshield® HDT™ Metal-Cored Wire and licensed Process HDT Waveform, Process HDT provides a complete GMAW-C solution for high-deposition, multi-pass welding applications. Developed to be a simple, cost-effective solution, Process HDT can provide single-wire deposition rates in excess of 35 lb/hr (16 kg/hr) while eliminating the complexity of Tandem MIG.

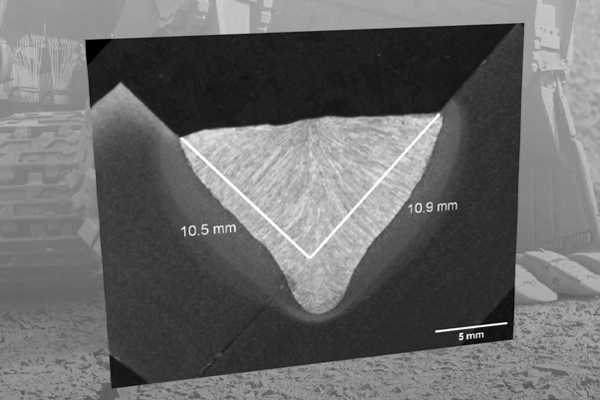

The Metalshield HDT metal-cored wire was designed specifically for providing a smooth, controlled droplet transfer and reduced spatter in high-amperage applications. It is formulated to resist porosity as well as offer excellent weld profiles and good toe wetting for fatigue-resistant welds.