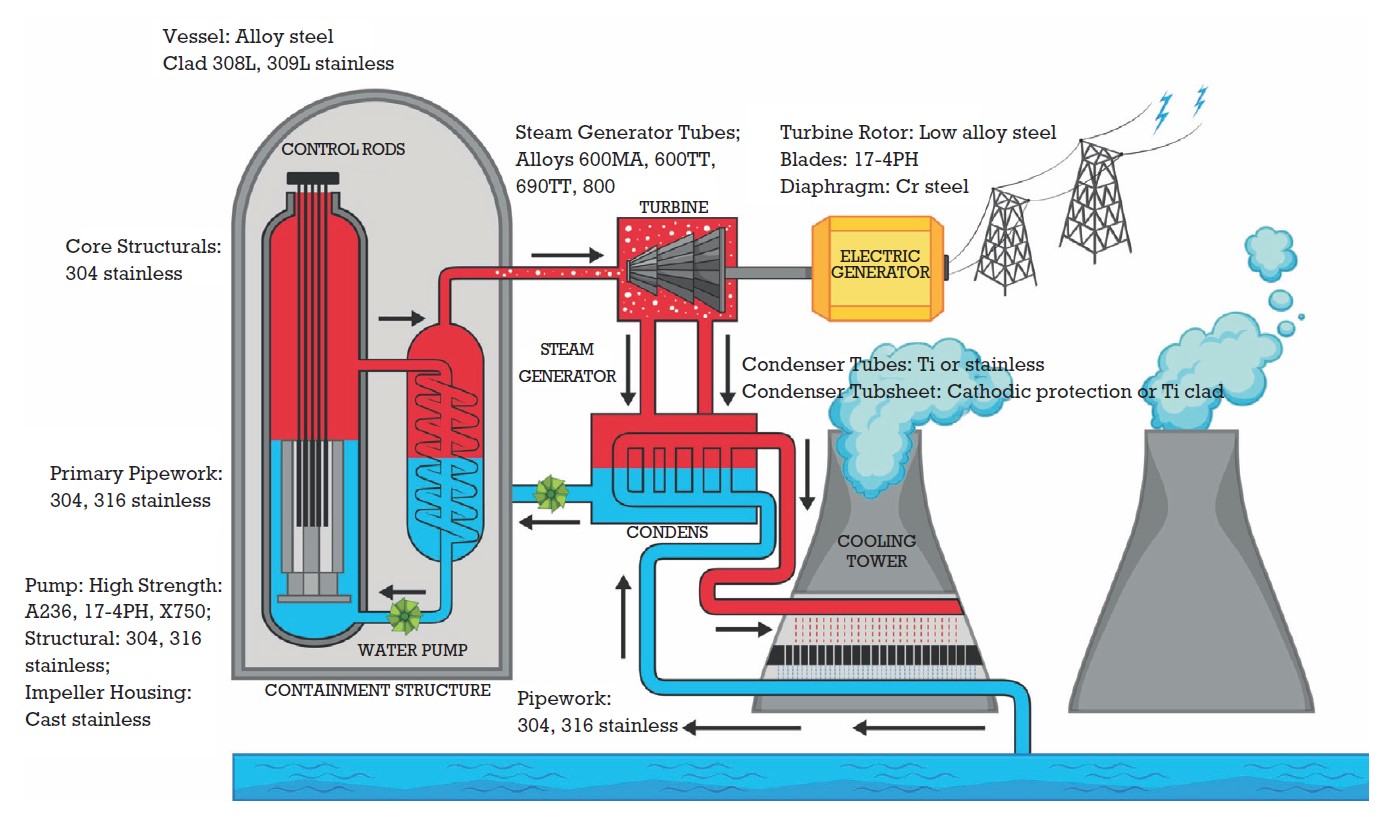

According to the World Nuclear Association, approximately 440 nuclear power reactors are operating, generating about 10% of the world’s electricity. More than 55 power reactors are under construction, 90 have been ordered or planned, and 300 are proposed, mainly in Asia. Because nuclear power has zero carbon emissions and is a reliable domestic energy source, there is a renewed desire to keep existing plants online. However, these plants may need replacement components and other enhancements to ensure safe operation while extending plant life. With the industry poised to see an increase in nuclear welding activity, it is worth revisiting the critical role filler metals play (Figure 1).

For example, in nuclear power plants, steam generators provide a similar function as heat exchangers; however, the stakes are higher. A small defect in fabrication can lead to radiation transfer from irradiated to non-irradiated water. Other welding applications include those on reactor pressure vessels, pressurizer vessels, reactor coolant piping, line valves and safety valves, as well as the nuclear facility’s structural elements and supporting infrastructure.

Quality assurance bodies

Safety is the top priority in the nuclear industry, and the industry must adhere to a strict set of rules and standards for safe operation and quality assurance during the construction and operation of nuclear handling sites. The leading quality assurance bodies include:

- The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) Section III details the quality requirement for components in nuclear power plants.

- The RCC-M, “Regles de Conception et de Construction des Materiels Mecaniques des Ilots Nucleaires PWR” (“Construction Rules for the Mechanical Components of PWR Nuclear Islands”), which gathers within one set of

- all design and construction practices relating to the mechanical components of French pressurised water reactor nuclear islands.

- ISO 3834, which provides welding best practice details for metals and ensures quality adherence for national and international use.

Verified assurance

When searching for filler metals, look for a supplier with a Quality System Certificate (QSC) issued by ASME, which verifies a Material Organization’s quality system program. The QSC certificate indicates a quality system in which the company’s operations, processes and services related to the procurement, manufacture and supply of material and source material are performed in accordance with the ASME BPVC, Section III requirements. ASME audits the certificate holder frequently, confirming adherence to ASME codes.

By working with QSC holder, fabricators and contractors performing nuclear welding are assured that their consumables:

- Are produced with the strictest quality control measures,

- Meet codes for nuclear pressure vessels,

- Perform with good weldability and high operator appeal, promoting consistent and high-quality results,

- Provide chemistries that offer excellent mechanical properties and performance in extreme service environments (e.g., high temperatures, resistance to corrosion and brittleness from neutron irradiation).

End-to-end transparency

Nuclear filler metal customers need complete transparency at every step of the process. The flow chart (Figure 2 abbreviated for clarity) demonstrates the close coordination between departments within a filler metal manufacturing organisation.

For customers to gain a fuller appreciation of “nuclear quality,” consider these details of fulfilling a nuclear filler metal materials order:

- Customer order request fielded by sales team. The nuclear filler metals team confirms that the technical specifications and quality specifications comply with the requirements from the applicable welding and nuclear codes. To have an independent eye, the quality team then independently reviews the work of the nuclear and customer teams.

- The order review summarises the technical and quality requirements, which the sales team then shares with the customer. Good communication confirms that the customer and filler metal supplier work in harmony, and it also creates the opportunity to discuss any questions or deviations that may arise. Only after all details are reviewed and confirmed does the order move to the logistics team.

- The logistics team determines if the order can be fulfilled with existing stock, if the order should be produced in-house or by audited and verified subcontractors, whether the order should be produced as a single batch, and what type of batch ID and package marking/labelling is required.

- After the product is produced or sourced, the nuclear team creates a Quality Plan and a Test Traveler, which are the most critical elements. The Test Traveler consists, for example, of the full scope of tests and welding parameters required by the nuclear design code, customer technical specifications and quality specifications. The Test Traveler and the Quality Plan are essentially the same, but the first is an internal document, and the second is a customer document (which is also used when customers request third-party inspection).

If the customer does not specify the required tests, the supplier interprets the tests required by the code (e.g., material chemistry verification, destructive, non-destructive, etc.) and specifies them in the Test Traveler. In all cases, when a Quality Plan is requested, the customer must review and approve it. - After laboratories (internal, external or both) complete their tests, the nuclear team reviews and signs all the test results; an independent quality team then double-checks the nuclear team’s work, confirming all results and processes comply with specifications and codes.

At that point, a certificate of nuclear conformance is issued. - Only after the customer reviews and approves the certificate are the nuclear filler metals released for shipping.

Customer support

In addition to providing nuclear customers with filler metals of the highest quality, a nuclear filler metals suppliers should also be able provide support in other areas:

- Operator training. Application engineers and field technicians can provide on-site training and operator support.

- Equipment and system development, including those for manual GTAW, orbital GTAW and cladding.

- Document management via a welding documentation software platform to control all the procedure qualification records (PQRs), welding procedure specifications (WPSs), welder performance qualifications (WPQs) and maintain full traceability of welds.

Using “nuclear quality” filler metals is just the first step in achieving “nuclear quality” results. In the next instalment of this column, we’ll explore some of the reactor components shown in Figure 1 and how the materials selected meet the needs of the service environment. Follow-on articles will provide guidance for filler metal selection and process-specific welding advice.

Meet the columnist

Peter Stones IEng MWeldI IWE/EWE

Peter Stones IEng MWeldI IWE/EWE

As part of the ESAB Specialty Alloys Group, Peter is technical support for stainless and nickel alloy filler metals. Peter is actively involved with TWI and is a non-executive director of The Welding Institute.

Peter worked for Sandvik for 10 years and was Global Product Manager for Sandvik Welding up to 2018, when ESAB purchased the filler metals business.

Email: Peter.stones@esab.com