Over the past 60 years, Hart has established itself as a leading stockholder and master distributor of nickel alloy piping products to the oil & gas and (petro) chemical industries. With vast experience in supplying nickel alloy piping packages for projects and day-to-day requirements, Hart offers customer-focused service and timely delivery of high-quality products. Stainless Steel World met with Lizette Hartholt in the company’s headquarters in the Netherlands to learn how, despite some exciting changes, Hart’s focus on quality and service in their niche industry has remained unchanged.

By Joanne McIntyre, Stainless Steel World

Stepping into the Hart headquarters in the town of Nijkerk, there is a buzz of activity. The team seems even more energised than usual, and the reason soon becomes apparent once I sit down with Lizette. “We want to inform the market that Hart BV changed hands on the 1st of March 2023 and remains under private ownership. As a company, we will continue to operate independently, just as we have for the past 60 years. As this new chapter starts, the new ownership will enable Hart to continue strengthening its position in the nickel alloy piping market.”

Having taken over the reins as General Manager, Lizette is leading the company into this new chapter with a strong sense of continuity by retaining the focus on customer service and quality for which the company has long been known.

“In some ways, it’s the end of an era,” continues Lizette. “Henry Hart successfully led and expanded the company since 1991. He built it up from a small niche supplier of low alloys and stainless steel to a major player in the nickel alloy business worldwide. While he is moving on to new projects, in a practical sense, very little has changed. We have the same vision and strategy going forwards. Our new owners want us to improve, be healthy, grow and strengthen our position in the market. 2022 was a great year for Hart, and this year is shaping up to be equally strong. In the near future, you will hear more about our expansion plans for 2024 which we are currently developing. Looking to the future, we are very excited!”

Strong market performance

For the past two years, the Hart team has seen solid growth in demand for its specialist nickel alloys. “This growth is geographically widespread; the industries we serve are thriving across the Middle East, Asia, and Europe. Any lingering post-covid supply chain issues have been resolved, and our suppliers have resumed normal operations,” explains Lizette.

For many decades Hart has supplied nickel alloys to the oil & gas, chemical and petrochemical markets. “Worldwide, we see a strong trend for plants in these industries to become greener; they need to produce fewer emissions, a smaller carbon footprint, and be powered by renewable energies. This has created a wave of investments to fund new plants and upgrade existing facilities.”

Another emerging trend is the development of emission-reduced steel, new recycling facilities and plants to produce biodegradable materials. “These emerging industries are an important part of our business today. The plants operate under harsh conditions, requiring significant quantities of nickel alloys.”

“Another sector experiencing strong growth is the pharmaceutical industry, which made substantial profits during the pandemic and is now focusing on investing in the future. This trend is connected to the global phenomenon of ‘reshoring’. Companies in many sectors realise that they were too reliant on imports from developing companies in the past. So, they are moving production closer to home to control and future-proof their supply chains.”

“Events in Ukraine have highlighted once again how dependent some countries are on others for raw materials, with the war significantly impacting the supply chain, creating energy surcharges, and causing spikes in the nickel price. While working in such a global business as alloy supply is interesting, it also makes it difficult to predict the future.” “One of Hart’s core strengths is that we always do well despite challenging circumstances. This is due to our financial stability and well thought through approach, with any risks we take being carefully calculated.”

High stock levels

“Our focus is very much on working closely with our customers and suppliers,” explains Lizette. “We believe in keeping our stocking levels high and the shelves full, and our customers know they can always get what they need from us. High stock levels mean we always have the capacity to service our customers and allow expansion. The market is still unpredictable, with lead times on nickel alloy pipes longer than stainless and carbon products due to ongoing raw material issues. It is still very difficult to predict the market. The aerospace and oil & gas industries, (both of which consume significant quantities of nickel alloys), are still enjoying growth. Some product forms have a much longer lead time than others. Another factor impacting lead times is that global vacuum (re)melting capacity does not meet current demand. This leads to certain (nickel) alloys having a longer lead time than others.”

“With Hart, what you see is what you get, and our customers appreciate that.”

Project management

Hart employs strong project management to fine-tune in-house processes and ensure smooth execution. “This involves every department, from sales to purchasing, quality, packing and logistics. Our team thoroughly understands the specifications our customers work with, and as orders progress, they ensure every top-up meets the requirements. Large order fulfilments start with an internal kick-off meeting so everyone is aware of the specifications, which are re-checked every time the subsequent order phase arises.

In order to maintain continuous improvements within our organisation, upon completion of a project, a debriefing with the client allows us to evaluate the process. Debriefs are a valuable learning moment; we discuss things that went well and where we can prevent hiccups in the future to constantly improve. It’s all about people and understanding what we need from each other to make every project a success.

We make it our policy to go the extra mile. We don’t shy away from a 200-page specification if a loyal customer needs our help!” The Hart team handles orders of any size, from complete large-scale projects to small one-off orders. “This can save customers a lot of time, money and effort,” adds Lizette.

Learning culture

The Hart team has a high level of technical knowledge and a strong learning culture. This is reinforced with ongoing training to enable them to meet customer requirements and handle complex and challenging projects successfully.

“Repeat training is both an opportunity to bring new staff up to speed on our processes and to update the knowledge of the long-term staff. It’s an opportunity for us to learn from each other, so we make time every week to address a different aspect of the business.” A new back-office manager has streamlined operations in that department, and several new staff members have complemented the sales team.

“Change brings opportunities; everyone who joins brings something new to the table, which is incredibly refreshing and creates an evolution in our business practices,” smiles Lizette. “Everybody has a unique approach, and this is what we call the ‘heart of Hart’. We have a diverse group of nationalities and personality types, which helps motivate people who are open to learning. It’s very stimulating for our company as a whole.”

Uncompromising quality

“Quality is essential in the nickel alloys business,” Lizette explains. “We source products from approved and renowned manufacturers, mainly from Western Europe, the United States and Japan. Our supplier relationships are hugely important; we can trust them to consistently deliver what we order. Annual reviews with each supplier are learning moments to discuss possible improvements. These are an important part of our learning culture, where we share experiences of the past year and identify any points for improvement. It’s a valuable opportunity to provide feedback from our clients to our suppliers, which is greatly appreciated.”

Increase in specs & testing

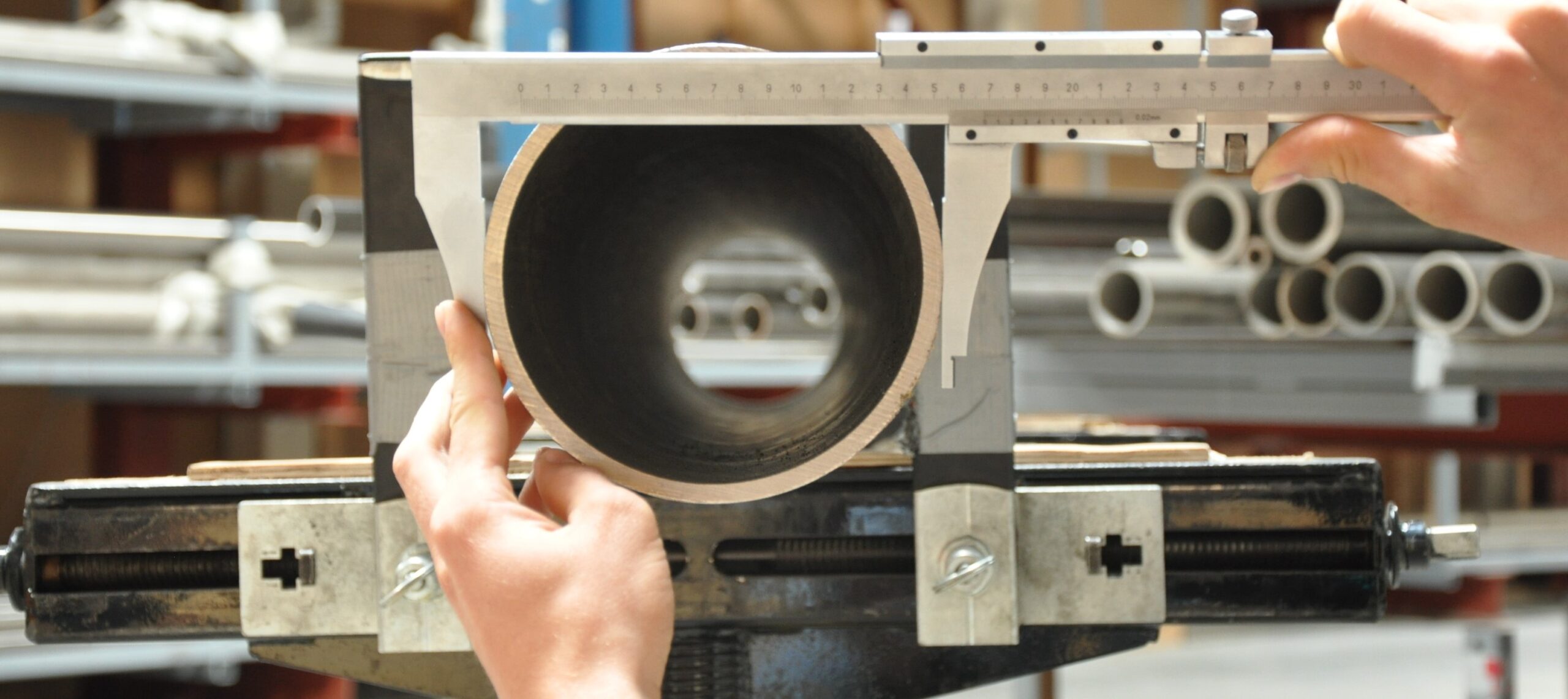

Hart has the in-house technology to create added value for its customers with a variety of services. These range from cut-to-size pieces, bevelling and colour coding to additional marking, and the company is PED certified to remark materials. It also performs a wide range of materials testing, and Lizette explains that demand for testing is growing year-on-year. In addition, Hart b.v. is Aramco approved.

“For some time, we’ve noticed that customers are demanding more checks on materials, additional verification that the information on certificates is correct, and adding more specifications. One of the reasons is that some applications have become more demanding and complex, so additional assurance is required that materials will perform as expected. Another reason is the increased number of nickel alloy manufacturers globally. While many mills produce quality materials, others do not. When end users encounter material failures, the standard response is to apply additional specifications to avoid future problems. We emphasise that dealing with the right supplier minimises the chance of something going wrong. The concept of quality has to be an intrinsic part of your work philosophy. Most end users believe that quality comes first and price second. However, there is often a conflict between what engineers want and what buyers can afford. It’s a challenging balance, especially when prices are as high as they are now.”

Loyalty of clients

With its wide product range and extensive in-house materials knowledge, Hart has built up a loyal customer base. “We aim to unburden our customers from any concerns they have regarding nickel alloys. Today, a key concern is a lack of personnel, with companies across Europe experiencing staff shortages. They now rely on trustworthy suppliers who understand their needs and are willing to work closely with them. Many customers have been with us for years, through good times and bad, and we’ve looked after each other. Ultimately, this business is about people; many companies supply alloys, but the relationship between the supplier and the customer makes all the difference.”

“We will go the extra mile for our loyal customers, finding the best solutions for them. Reliability is important; our customers know they can trust us when we say we have the material in stock or quote a delivery time. With Hart, what you see is what you get, and our customers appreciate that.”

About this Featured Story

This Featured Story appeared in Stainless Steel World September 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.