Situated 300 kilometres from shore and at water depths of 1300 metres, the location of the Aasta Hansteen gas field places it far from the current established infrastructure. The field will be run from Harstad, Statoil’s new Operations North organisation. The planned field development, including a 70,000 ton SPAR platform, will be the first such installation on the Norwegian Continental Shelf (NCS).

The SPAR floating installation, consisting of a vertical column moored to the seabed, features conventional topsides and processing facilities. Once installed, the risers transporting the gas from the seabed to the platform and further to the Polarled pipeline will be pure steel, another first for the NCS. Aasta Hansteen will be the largest SPAR platform in the world and is the biggest ongoing field development project in the Norwegian Sea. One of the main projects in Statoil’s portfolio, production start-up is expected in 2018.

Specialized equipment & materials

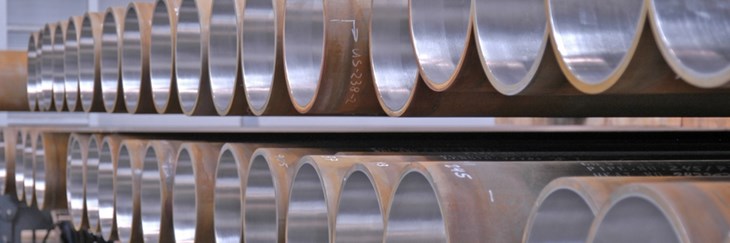

The BuBi® (short for BUTTING – Bi-metal) pipe is a corrosion resistant pipe which is telescopically aligned inside a pipe in carbon-manganese material. The tight mechanical bond between the pipes is achieved in a hydroforming facility. For many years these pipes have been successfully used in very demanding and sensitive onshore and offshore areas of the oil and gas industry where they are used as pipelines, riser pipes and SCR-pipes for highly corrosive media. Mechanically lined pipes provide several advantages in these applications such as:

Pipe End Plugs are typically used during the construction and fabrication of pipe spools and piping systems; these fail-safe tools cap open-ended pipe, facilitating hydrostatic leak and strength tests. Pipe End Plugs provide many benefits: hydraulically activated, they are quick and easy to install, providing a safe and cost effective solution. STATS range of Pipe End Plugs cover two separate products, the I-PEP™ which fits internally to the pipe and the E-PEP™ which grips the pipe externally.

Successful collaboration

before the entire structure is completed and towed to its final destination in the Norwegian Sea. First gas is expected in 2018.