In this article, Tommi Purtilo from Stalatube delves into the key advantages of using duplex stainless steel for pipe support brackets, with a focus on its weight-saving potential and overall performance benefits.

By Tommi Purtilo, Business Development Manager, Stalatube Oy

In the world of industrial applications, the choice of materials can significantly impact both performance and efficiency. One such material that has been gaining attention is duplex stainless steel, particularly in the context of pipe support brackets. A study carried out by Stalatube highlights the remarkable benefits of using duplex stainless steel, specifically EDX2304, over traditional austenitic acid-proof steel, EN 1.4404.

Understanding duplex

Duplex stainless steel is a family of stainless steels that combines the best attributes of both austenitic and ferritic stainless steels. This unique combination results in a material that offers excellent strength, corrosion resistance, and durability. The EDX2304 grade, in particular, is known for its high yield strength and impressive mechanical properties, making it an ideal choice for demanding applications.

Weight-saving potential

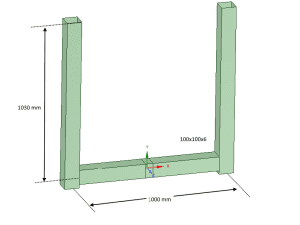

One of the most compelling advantages of using duplex is its significant weight-saving potential. The study compared two pipe support brackets: one made from austenitic acid-proof steel EN 1.4404 and the other from duplex stainless steel EDX2304. The results were striking. The mass of the EN 1.4404 bracket was 56.057 kg, while the EDX2304 bracket weighed only 31.479 kg. This translates to a remarkable 43.84% reduction in weight.

The original profile for acid-proof steel was 100x100x6, and for duplex, 86x86x4. This weight reduction is not just a matter of convenience; it has profound implications for various industries. Lighter components can lead to easier handling and installation, reduced transportation costs, and a significantly improved carbon footprint. In applications where weight is a critical factor, such as in the aerospace, automotive, and mobile applications, the use of duplex stainless steel can result in substantial cost savings and improved efficiency.

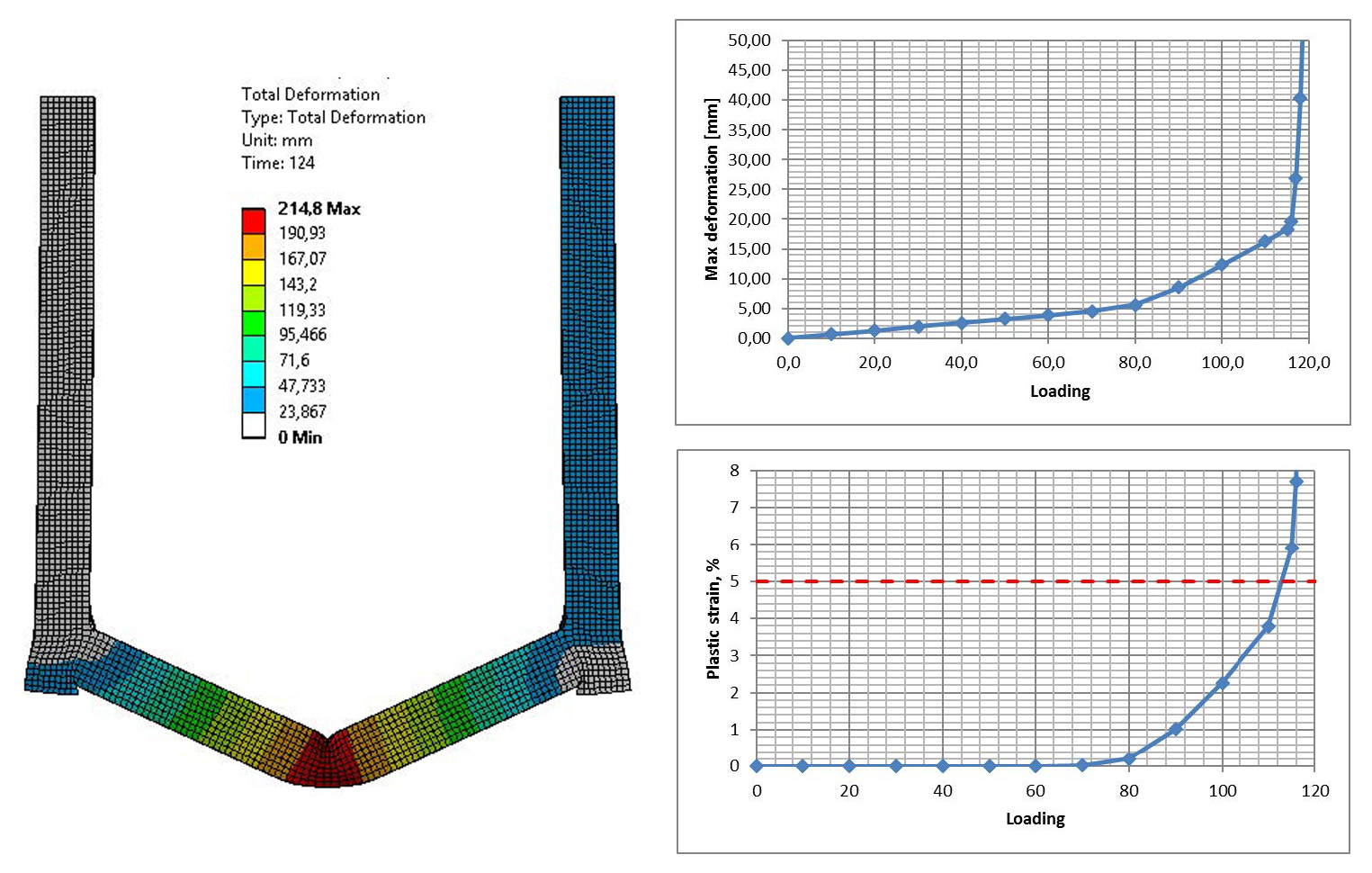

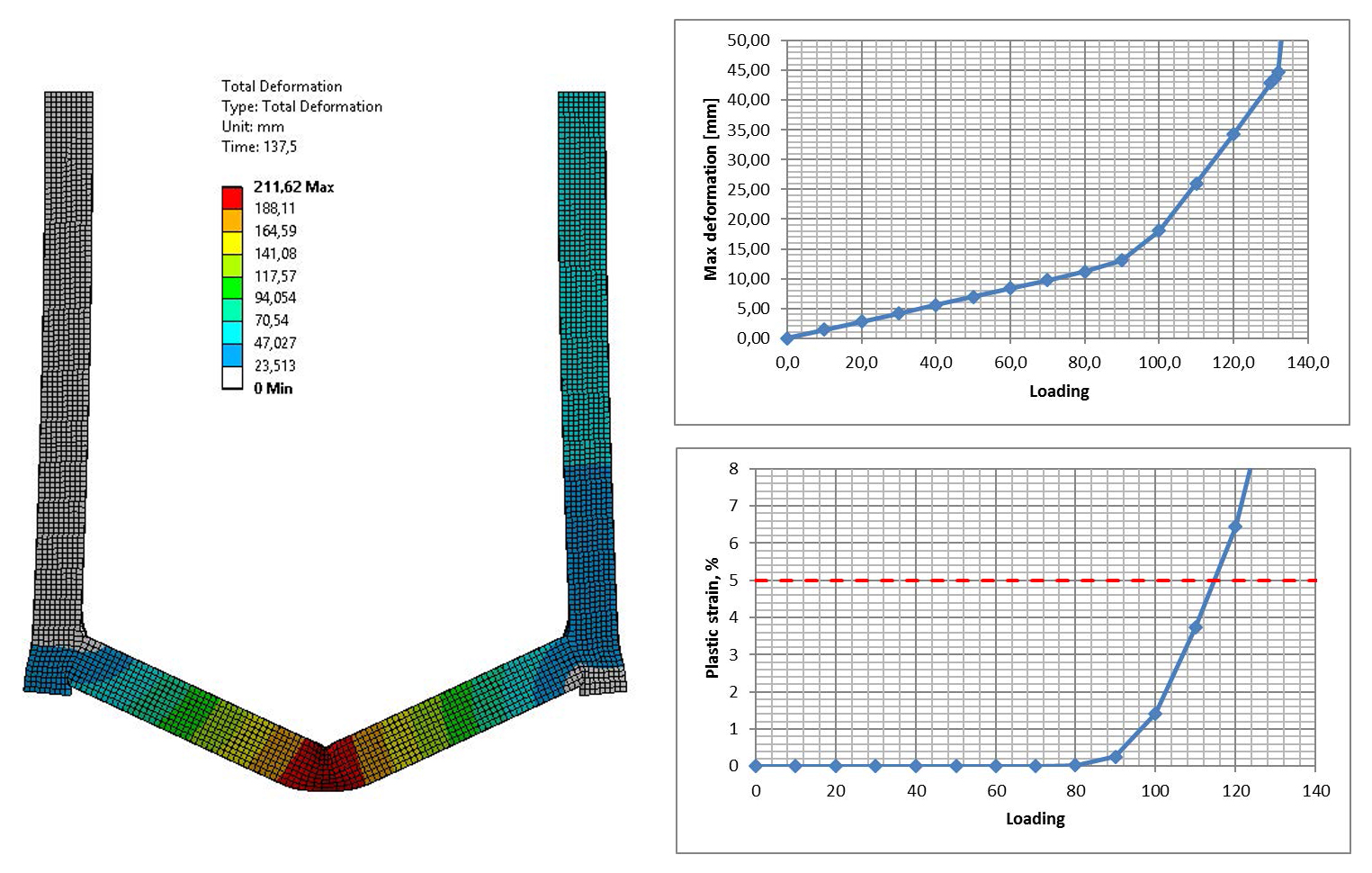

Enhanced load capacity

Despite its lighter weight, duplex stainless steel does not compromise on strength. The study revealed that the EDX2304 bracket could handle at least the same load as the EN 1.4404 bracket, with an additional 15% capacity when considering the ultimate load. This means that not only can duplex stainless steel reduce weight, but it can also enhance the load-bearing capacity of the structure.

This combination of high strength and low weight is particularly beneficial in applications where both factors are critical. For instance, in the construction of offshore infrastructure, bridges, and other steel structures, using duplex stainless steel can lead to safer and more efficient designs.

Superior corrosion resistance

Another significant advantage of duplex stainless steel is its superior corrosion resistance. The EDX2304 grade, with its balanced microstructure, offers excellent resistance to stress corrosion cracking, pitting, and crevice corrosion. This makes it an ideal choice for harsh environments, such as marine and chemical processing applications, where corrosion resistance is paramount.

The enhanced corrosion resistance of duplex translates to longer service life and reduced maintenance costs. Structures and components made from duplex are less likely to suffer from corrosion-related failures, leading to improved reliability and lower lifecycle costs.

Forward-thinking approach

The study underscores the numerous benefits of using duplex stainless steel, particularly EDX2304, in pipe support brackets. The significant weight savings, combined with enhanced load capacity and superior corrosion resistance, make duplex an attractive choice for a wide range of industrial applications. By opting for duplex, industries can achieve more efficient, cost-effective, and durable solutions, ultimately leading to better performance and sustainability. In conclusion, the adoption of duplex represents a forward-thinking approach to material selection, offering tangible benefits that extend beyond mere weight reduction. As industries continue to seek innovative ways to improve their operations, duplex stainless steel stands out as a material that delivers on multiple fronts, paving the way for a more efficient and resilient future.

About the author

About the author

Tommi Purtilo is Business Development Manager for Energy Industry, hollow sections & profiles at Stalatube Oy in Finland.

About this Tech Article

Appearing in the June 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.

About the author

About the author