Ratnamani Metals & Tubes Limited

| Year of inception | 1983 |

| Work force | 3000+ |

| Revenue | USD 580 Mn. |

| Manufacturing location | Indrad and Kutch in the state of Gujarat, India |

| Sales Offices | India – Ahmedabad, Mumbai, New Delhi, Hyderabad North America – Sugarland, Texas Europe – Switzerland Middle East – KSA, UAE |

Seamless Tubes & Pipes

The Seamless facility at Indrad comprises of:

- Two Hot Extrusion Presses (4500 Ton & 1700 Ton capacity),

- High Speed Cold Pilger Mills & Draw Benches

- Bright Annealing / Conventional Annealing Furnaces

- Coiled Tubing Lines

- Integral Low Finned Tubes

- Cold Finishing lines.

The Annealing and NDT processes are also NADCAP certified.

Product Offering

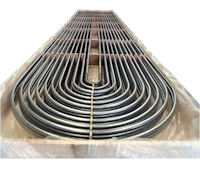

- Nickel Alloy / Stainless Steel Heat Exchanger Tubes (Straight / U bend condition)

- Boiler Tubes

- Integral Low Finned Tubes (Straight / U bend condition)

- Nickel Alloy / Stainless Steel Instrumentation Tubes (Straight / Coiled)

- Seamless Pipes

- Heater Pipes

- Hollow Bars

Welded Tubes & Pipes

The Welded facility at Kutch comprises of:

- Fully automized Tube Mills for Stainless Steel Heat Exchanger Tubes

- Titanium Welded Tubes

- Coiled Tubing Lines

- JCO Forming Press

- Inside and Outside Welding system

- Tube Mills for Welded Pipes

- Bright Annealing / Conventional Annealing Furnaces

- Cold finishing lines

Product Offering

- Stainless Steel Welded Heat Exchanger Tubes (Straight & U bend)

- Titanium Welded Tubes

- Seam-Welded Integral Low Finned Tubes (Straight & U bend)

- Coil Tubing

- Welded Pipes (With OR Without Filler Wire)

- Pipes with internal / external Coating

- Induction Bends

All the inspection and testing facilities are in-house. The NDT personnel are qualified as per ASNT Level II & III, EN to ensure that the products manufactured are of requisite quality. The Quality Assurance laboratories at Indrad & Kutch facilities are accredited to ISO IEC 17025.

Certification

- ISO 9001:2015

- ISO 14001:2015

- ISO 45001:2018

- PED

- ADW0

- NORSOK

- Marine

- AS 9100D

- NADCAP

- ISO IEC 17025

- IATF 16949:2016

- VdTUV 418

- UDT

- NSF/ANSI/CAN 61

Grades manufactured

- Nickel Alloys

- Austenitic, Super Austenitic, Ferritic, Super Ferritic, Martensitic, Duplex, Super Duplex,

- Titanium

Spectrum of Customers

- Refineries & Petrochemicals

- Chemical & Fertilizers

- Green Energy

- Thermal, Nuclear and Solar Power Plants

- Atomic Energy

- Aerospace

- Defense

- LNG

- Automotive, CNG

- Marine

- Desalination

- Pharmaceutical

- Pulp & Paper Industries

- Food & Dairy

- Sugar

- Structural Sections