BIG KAISER, the premium high-precision tooling systems and solutions for the metalworking industry, has released a new set of insert grades for its indexable tools—C-Cutter Mini, C-Centering Cutter and Fullcut Mill. The new inserts are optimized to extend tool life in stainless steel or aluminum.

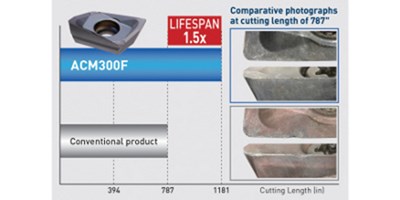

Suited for peck-drilling, ramping, helical and shoulder milling, the Fullcut Mill is now available with the PVD-coated carbide ACP300 with nanometer-level thickness and ultra-multilayered TiAIN and AICrN film. The new ACM300F is designed specifically for stainless steel work. The ACM300F boasts excellent fracture and welding resistance and has demonstrated a lifespan 1.5× of conventional inserts in testing.

The new ACM250F stainless steel grade can be used for chamfering and spot drilling with the C-Cutter Mini or C-Centering Cutter. PVD-coated carbide with excellent smoothness, the new grade resists welding and chipping due to the ultra-multilayered thin-film structure made of AlTiN and TiAlCrN.

The DS20 for aluminum/non-ferrous metals is available for the C-Centering Cutter. Its diamond-like DLC coating is ultra-smooth with a low wear coefficient and superior welding resistance, and effectively prevents burrs.