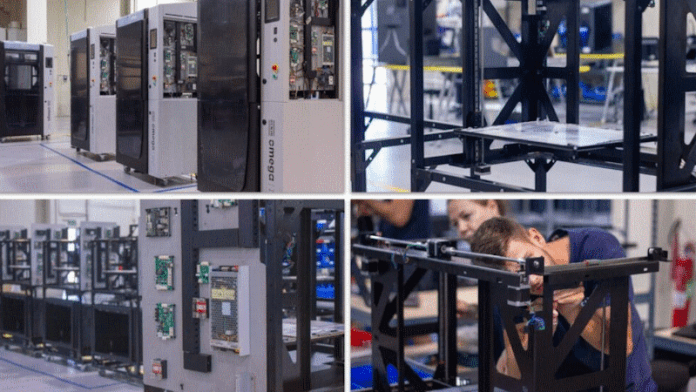

BCN3D, a major manufacturer of 3D printing solutions, has secured a pivotal investment round to fuel its growth in the light industrial additive manufacturing (AM) market. This announcement also celebrates the first anniversary of BCN3D’s flagship industrial FFF printer, the Omega I60, renowned for its capability to produce large, durable prototypes and end-use parts like tooling, jigs, and fixtures.

BCN3D highlights the success of clients like Wisconsin Precision Casting and Camper, whose use of the Omega I60 exemplifies the printer’s performance in action. Wisconsin Precision Casting is an investment casting foundry based in the United States that supplies low to medium volume castings to various sectors. They integrated FFF 3D printing technology into their operations to complement the traditional lost wax casting process, particularly for low-quantity batches. Since adopting 3D printing, they now operate a fleet of nine FFF 3D printers, including the Omega I60, to produce plastic patterns using 3D printing casting filament to create molds around them. The Omega I60 has proven extremely useful thanks to its capacity to print many parts in one go at speeds of up to 150 mm/s, significantly reducing production times.