The Plug-and-Play Alternative to 316L | Same Performance • Lower Cost

For over a century, Aperam has blazed a trail in material innovation and development. Since its inception, each decade has been marked by notable developments in stainless steels targeting particular industrial segments, from ferritic grades for automotive and mobility applications to martensitic grades for cutlery and cutting tools, as well as duplex for tanks and the energy industry. Today, that long tradition of innovation continues as Aperam upholds its role as a leading developer of world-changing, sustainable materials. The release of its latest grade of austenitic stainless steel, 316A, promises to be a global game-changer.

By Joanne McIntyre, Stainless Steel World

Innovation is an integral part of Aperam’s DNA, with the company consistently investing in cutting-edge research at its three state-of-the-art R&D facilities. Every day, more than 150 dedicated staff members research to both develop and fine-tune the solutions required to meet today’s most challenging applications and the demands of tomorrow’s world.

Innovation Lab – for today and tomorrow

In recent years, Aperam has established the Innovation Lab, a concept that links its research facilities by focusing on the materials required for final processes and the properties needed by end-users now and in the future.

“To discover the materials innovations required now and in the future, we utilise our extensive research capabilities in co-development with key industry partners,” explains Reiner Steins, Chief Innovation and R&D Officer. “Our co-developers in this exciting endeavour are customers, technical universities and institutions, and the leaders in various industries. With our extensive research capabilities, we are able to create clusters focusing on developing expertise in various fields, such as decarbonisation, construction, energy, the mobility industry, etc.”

From feasibility studies to industrial testing, the Innovation Lab provides in-depth expertise in metallurgy, corrosion science and solution design.

“The Innovation Lab focuses on how customers actually use materials in their facilities today, and how they will do so in the future in emerging markets. We can replicate the challenges that real end-us-ers face, and then develop new materials that excel in those applications. It’s practically applicable knowledge that addresses what real end users need in the field, starting with identifying their pain points and then working on finding the best possible solutions.”

Anticipating future markets

For emerging applications, Aperam’s co-development activities are driven by the needs of customers and key partners. However, the Innovation Lab also operates proactively, anticipating how the properties of stainless steel can contribute to future applications, sometimes years before they are needed.

“Prime examples are the mobility and energy markets, where we have been looking at how we can adapt material properties to enable customers to be at the forefront of their sector. We’re solving the problems of today, while anticipating the needs of tomorrow,” explains Gwénaëlle Le Meur, Director of Market Innovation & Development.

“New material needs can arise very quickly in response to emerging technologies, with recent examples including electrolysers, EV batteries and fire containment for those batteries, etc. In this way, we are a problem-solving material provider for new applications.”

The pain points that material developments can alleviate are not just related to the physical properties of the materials, but also cost reduction through the use of specific grades. This is particularly apparent as the company’s activities are now all linked to one core consideration: sustainability.

Embracing sustainability

The drive for sustainability in the stainless steel industry relates not only to the production of greener steel, but also to the ability of those greener materials to help customers achieve their own environmental targets by using low-carbon raw materials. “A great example is electric vehicle batteries. The use of EVs is essential to meet Europe’s Green Deal targets, but the production of those batteries can also be made more sustainable depending on the stainless steel used in them. The CO2 footprint of the raw material itself can be very low if products such as Aperam infinite™ are selected. Both aspects are inherently linked because even as cus-tomers develop sustainable technologies, they want to build these using the most sustainable raw materials possible.”

“Therefore, the Innovation Lab enables Aperam to meet its long-held goals for sustainability, not only in terms of greener stainless steels with a low carbon footprint, less alloying elements, etc, but also by helping our key partners achieve their own goals in sustainable industries,” explains Mattias Candetoft, Global Business Development Manager.

During the manufacturing process, Aperam has taken extensive steps to reduce its own carbon footprint, and that of its products, through integration of its upstream and downstream activities in its Recycling & Renewables segment. ELG, as part of Aperam Recycling segment, operates in over 50 locations, securing high-quality scrap and optimising raw material supply. Recyco is Aperam’s subsidiary that turns industrial residues into reusable materials, while BioEnergia, a Forest management company in Brazil, provides sustainable bio-charcoal, reducing the company’s environmental footprint. By offering closed-loop solutions Aperam strengthens its partnerships while advancing the circular economy.

Introducing 316A – a true material breakthrough

European manufacturers are under increasing pressure to find new ways to curtail costs while maintaining the performance and durability of their products. At the same time, sustainability is a key concern as CBAM and other regulations seek to limit emissions. Aperam’s Innovation Lab has just released alloy 316A, a true breakthrough in material innovation which meets all of these needs.

European manufacturers are under increasing pressure to find new ways to curtail costs while maintaining the performance and durability of their products. At the same time, sustainability is a key concern as CBAM and other regulations seek to limit emissions. Aperam’s Innovation Lab has just released alloy 316A, a true breakthrough in material innovation which meets all of these needs.

316A was designed to give manufacturers the corrosion resistance of 316L at a significantly lower price. The breakthrough was the discovery of a remarkable effect that occurs when one strikes the right balance between the alloy’s silicon content and its other chemical elements, such as molybdenum. The effect is a synergy that ultimately allows for a lower-cost formulation without compromising performance.

Manufactured using high scrap content, 316A is fully aligned with European carbon footprint requirements and contributes to EU taxonomy objectives. For produc-ers operating under scope 3 emission constraints, 316A offers an opportunity to decarbonise without redesigning.

316A typically contains just 0.45% molybdenum content, which is less than a quarter of what its established counterpart contains. Instead, 316A uses more silicon (0.8 – 1%), a cost-effective alloying element that allows the material to match – or even exceed – the performance of 316L in some criteria.

316A’s comparability to 316L has been confirmed by standard electrochemical tests, as well as by industry-standard salt spray tests. Test results of the two grades are close not only for pitting and crevice corrosion at room temperature, but also for mechanical properties. This includes performance at high temperatures (e.g., 500°C) and low temperatures (e.g., -75°C).

316A: The plug & play solution

Because 316A is designed as a ‘plug-and-play’ solution, manufacturers can leverage its performance and cost-saving benefits with minimal need for investments or process adjustments. In fact, following successful test runs, several industrial fabricators have already seamlessly made the switch from 316L to the new 316A without altering any of their processing parameters.

Even for complex forming operations, no process adjustments are required when switching from 1.4404 (316L) to the new 1.4682 (316A). Comparative measurements of the forming limit curves confirm the equivalent formability of both grades.

There are no modifications in joining techniques either. Parameters for laser and TIG welding remain unchanged, with 316A offering particularly favourable wetting properties during copper brazing – an interesting advantage in applications such as heat exchangers.

A trail-blazer in alloy innovation

“At Aperam, we’ve been developing innovative solutions for demanding applications for several decades,” smiles Bertrand Petit, 316A Research Project Leader. “Time and again, we’ve created materials that have been game-changers for our customers and partners. Today, this is happening again with 316A. I’m confident in saying that this alloy will completely change the market, because it’s a grade with the same corrosion resistance as 316L but with a 25% lower alloying cost. 316A will change the landscape of the stainless steel market.”

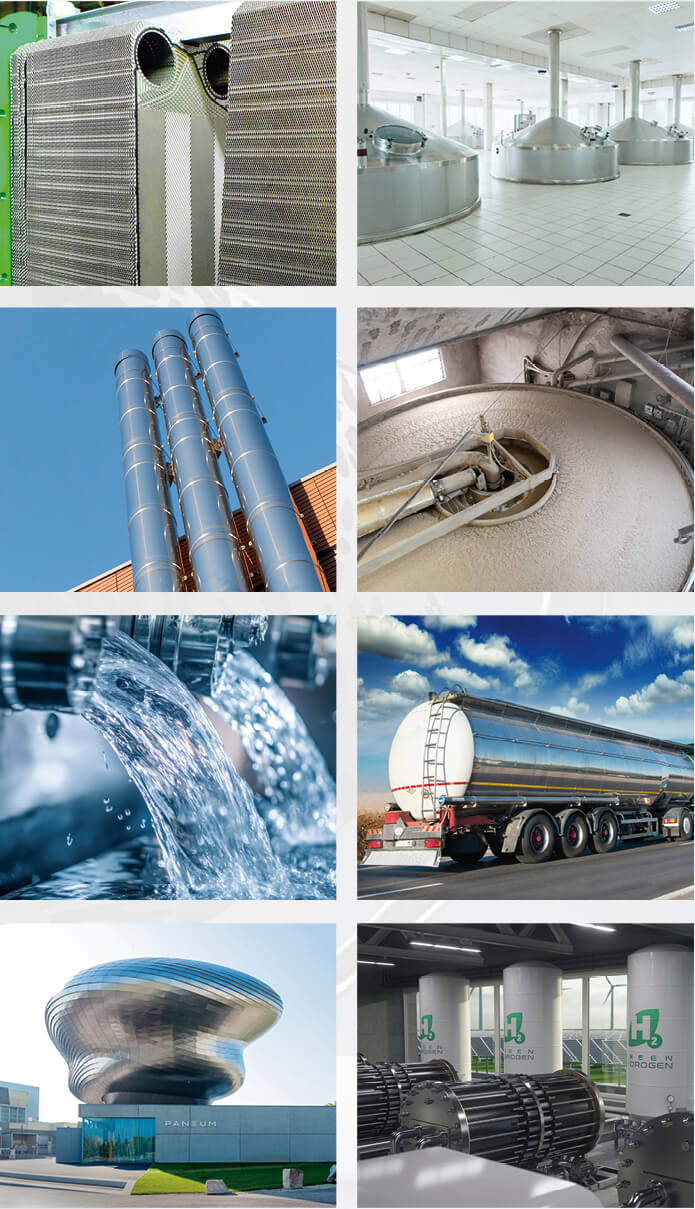

Key sectors that benefit the most from 316A

About this Featured Story

Appearing in the Conference & Expo 2025 Catalogue, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.