In recent years, advancements in extraction technology have created innovative, ambient air cleaning solutions to address these concerns. This article explores the employment of ambient air cleaning for large-scale fabrication and suggests effective strategies to safeguard and protect the wellbeing of workers.

By Chris Meacher, Nederman, UK

Welding and fabrication of large objects are an integral process in the construction of massive structures and heavy machinery. These processes result in airborne contaminants in the form of fumes and particulate matter. The hazards produced during welding operations pose serious health risks to operators and other nearby workers. On-torch extraction is an effective method to control welding smoke and fume by capturing fumes close to the source before entering a worker’s breathing zone, but this becomes harder to control in large-scale fabrication.

The hazards of welding

Welding unavoidably generates a range of airborne pollutants, including metal fumes, particulate matter, and gases. These pollutants, when inhaled, can create impacts on human health that include asthma, acute pneumonia, cancer, and irritation of the throat and lungs, as well as metal fume fever, which has flu-like symptoms. The potential effects of exposure to welding fumes can increase the longer you are exposed. The challenges of maintaining good air quality become greater the more welding takes place.

Ambient air cleaning to complement on-torch extraction

On-torch extraction, while vital as the primary control method, can fall short in some circumstances when addressing the specific challenges posed by large-scale fabrication.

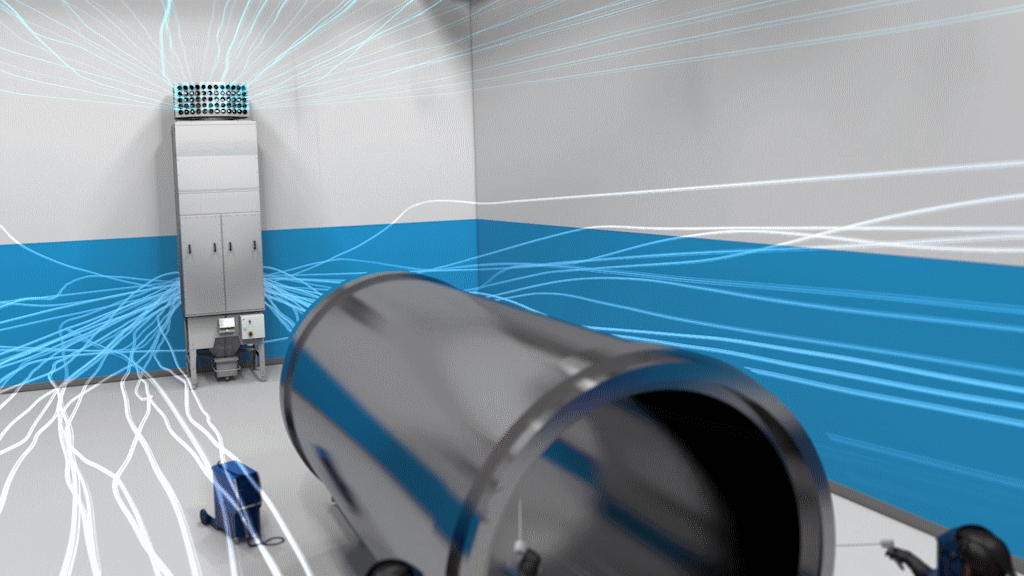

The efficacy of removing pollutants from large-scale fabrication changes from localised, at-source extraction to a wider vicinity extraction solution. Ambient air cleaning systems can be employed as a complement to on-torch extraction to remove airborne pollutants actively and consistently from the entire workspace. The systems provide superior airflow when strategically placed throughout an area, capturing all fumes and particulates and filtering them from the air, providing safe containment and preventing inhalation by workers.

Complementing on-torch extraction with ambient air cleaning creates a solution that helps to remove airborne contaminants.

How does ambient air cleaning work?

- Delivers clean, filtered air to the workshop at high speed at the highest level. Usually below the workshop ceiling.

- Breaks up dust and fume clouds that form near the ceiling.

- Dilutes the dust and fume-laden air with the rest of the factory air, creating a homogenous mass of air with a low pollutant concentration.

- Creates favourable air circulation within the workshop, directing polluted air towards the filter.

- Captures dirty air into the low-level intakes, removing dust and fumes with high-efficiency cartridge filters and returning the clean air to the workshop.

Situations in which ambient air cleaning could be a vital component:

- Welding on large objects

- Workshop areas with obstructions that make duct installation difficult.

- Changes in welding locations

- Protecting personnel and machinery outside of the immediate area

Some systems can both contribute to maintaining the wellbeing of worker health, and also business operations costs. Dynamic airflow control can be used to optimise the air exchange rate and maintain good air quality based on welding activity throughout the day. It can be ramped up when there is an increase in fabrication and reduced when the need is not as great.

Nederman solutions come with the peace of mind of keeping workers safe from the dangers of airborne contaminants without dramatically increasing business operation costs. In some cases, while the safety of people is always paramount, you can save time and money overall by implementing optimised extraction in your workplace. In addition to the reduction in operating costs, there is the cost of heating; Welding dust and fume clouds are warmer than the air close to the flow. The mixing and circulation of air equalises the temperature within the workshop, reducing heat loss throughout the factory and the amount of warm air extracted by ventilation fans.

Benefits of ambient air cleaning

Worker health & safety – Actively removing airborne contaminants as effectively and thoroughly as possible contributes to a healthier and safer working environment for welders and others actively involved in large-scale welding and fabrication.

Regulatory compliance – Adhering to strict environmental and occupational health regulations is crucial for large-scale industrial fabrication operations. Ambient air cleaning solutions are a smart choice to help companies meet and exceed these standards. They promote worker health and ensure responsible business practices are followed.

When it comes to metal fabrication, implementing an ambient air cleaning solution offers an efficient and adaptable solution to combat the health risks associated with airborne contaminants. It makes ambient air cleaning a viable, strategic investment that will improve workplace optimisation and help with company regulations. Ambient air cleaning solutions are the next step to improving workplace air quality and pave the way for safer and healthier working environments.

About this Tech Article

This tech article appeared in Stainless Steel World, June 2024 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.