Stainless 301 constant force springs are utliised in industries ranging from electric motor manufacturing to the automobile and aerospace industries, defence and many others.

By Srikumar Chakraborty, ex Technical Officer, ASP/SAIL, Freelance Consultant

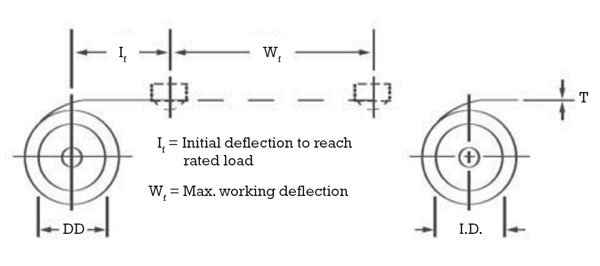

Constant-force springs are a variety of extension spring. They consist of a spiral of strip material with built-in curvature, where each coil wraps tightly around its inner neighbour. During extension, i.e. deflection, the inherent stress resists the loading force at a nearly constant (zero) rate. These products are well-suited to long extensions with no load build-up. During use, the spring is usually mounted by being tightly wrapped on a drum. The free end is attached to the loading force counterbalancing application, although this relationship can be reversed. Specifying the correct material for manufacturing the product is important to achieve the correct dimensions and properties of the strip.

Process technology

The raw material is a pre-stressed flat strip of spring material forming a virtually constant radius which coils around itself or onto a drum. When the strip is extended (deflected), the inherent stress resists the loading force like a common extension spring, but at a nearly constant (zero) rate. A constant torque is obtained when the outer end of the spring is attached to another spool and wound in either the reverse or the same direction. The most common metal used is stainless steel grade 301, considering lifecycle cost, properties, application areas, and industry. Other materials available include high carbon steel (limited applications), precipitation hardening stainless steel, Inconel etc. While Inconel may be more suitable for the spring action, the need to resist high loading forces and higher production costs are disadvantages of this material. The flat-shaped strip is produced by the continuous casting of liquid steel, which is finally re-rolled as a strip. Modern strip casting is the most recent innovative steel casting technology that integrates casting and rolling to avoid reheating, thereby reducing processing costs. Strip casting technology arose between 1980 and 1985 in developed countries where the main focus was on reducing capital costs and increasing productivity. In any hot rolling operation, the reheating furnace is a critical factor in determining end-product quality, as well as the total cost of the process. Energy use in a reheating furnace depends on production factors (e.g. stock, steel type), operational factors (e.g. scheduling), and design features. Globally, typical hot rolling energy needs are 2 – 2.4 GJ/t, highlighting the attractiveness of hot rolling for low-capacity facilities in small steel plants that greatly benefit from energy-efficiency improvements.

The raw material is a pre-stressed flat strip of spring material forming a virtually constant radius which coils around itself or onto a drum. When the strip is extended (deflected), the inherent stress resists the loading force like a common extension spring, but at a nearly constant (zero) rate. A constant torque is obtained when the outer end of the spring is attached to another spool and wound in either the reverse or the same direction. The most common metal used is stainless steel grade 301, considering lifecycle cost, properties, application areas, and industry. Other materials available include high carbon steel (limited applications), precipitation hardening stainless steel, Inconel etc. While Inconel may be more suitable for the spring action, the need to resist high loading forces and higher production costs are disadvantages of this material. The flat-shaped strip is produced by the continuous casting of liquid steel, which is finally re-rolled as a strip. Modern strip casting is the most recent innovative steel casting technology that integrates casting and rolling to avoid reheating, thereby reducing processing costs. Strip casting technology arose between 1980 and 1985 in developed countries where the main focus was on reducing capital costs and increasing productivity. In any hot rolling operation, the reheating furnace is a critical factor in determining end-product quality, as well as the total cost of the process. Energy use in a reheating furnace depends on production factors (e.g. stock, steel type), operational factors (e.g. scheduling), and design features. Globally, typical hot rolling energy needs are 2 – 2.4 GJ/t, highlighting the attractiveness of hot rolling for low-capacity facilities in small steel plants that greatly benefit from energy-efficiency improvements.

The full rated load of the spring is determined by the thickness and width of the material and the diameter of coil.

Smooth, uniform load

Stainless 301 constant force springs provide a smooth, even, uniform load throughout their entire length, providing a strong force yield within small spaces in the extensive linear range. The design calculation is normally based on the steel grade, i.e. composition, estimating the lifecycle of the spring in relation to the application area, processing sequences, width/ length, thickness etc. As the strength of the steel increases, the impact toughness and ductility reduces. This should be balanced by heat treatment to achieve improvements in fatigue properties in a corrosive environment.

Stainless 301 constant force springs provide a smooth, even, uniform load throughout their entire length, providing a strong force yield within small spaces in the extensive linear range. The design calculation is normally based on the steel grade, i.e. composition, estimating the lifecycle of the spring in relation to the application area, processing sequences, width/ length, thickness etc. As the strength of the steel increases, the impact toughness and ductility reduces. This should be balanced by heat treatment to achieve improvements in fatigue properties in a corrosive environment.

The constant force spring is so-named because it is a spring in which the force of motion is under constant exertion. The tightly wound roll works in a linear movement and does not obey Hooke’s law, but rather allows it to constantly produce force throughout its deflection. Constant force springs have practically no limits on their extension speed or acceleration of use because as the spring is unrolled, the restoring force resides in the portion of the ribbon nearest the roll. It can be fitted in several ways and extended partly or entirely. This gives a wide range of uses. Extension springs are used to apply a constant force at a set displacement in a wide variety of components.

Reference: AISI, Product Images from manufacturer