In Europe, the management of metal waste represents one of the most demanding challenges regarding materials present in municipal solid waste (MSW).

Text by Picvisa

Metals will occupy a prominent place in the European sustainable agenda for the next ten years in terms of the volume generated and the complexity of their identification, selection, and treatment.

According to the most recent data published by the European Environment Agency, the production of metal waste in Europe experiences steady growth, stemming from an increase in industrial activity and changes in consumption patterns. Metal waste (including ferrous and non-ferrous metals) represents a significant fraction of industrial and consumer waste. Its proper management is fundamental not only to reducing environmental impact but also to recovering valuable resources. The effective classification of metals, and especially of metal flakes/shavings, is crucial for their reuse and to ensure proper recycling.

Separation & recycling metal flakes

The classification and separation of metal flakes are considerably more complex than other materials such as plastic, textiles, or glass. Metal flakes require extremely advanced identification and classification technologies due to their heterogeneity and variable properties:

The classification and separation of metal flakes are considerably more complex than other materials such as plastic, textiles, or glass. Metal flakes require extremely advanced identification and classification technologies due to their heterogeneity and variable properties:

- Diversity of materials: Metal shavings can come from a wide range of products and industrial processes and be composed of different metals. Each metal has unique properties and requires different processing methods for recycling.

- Variable size and shape: Metal shavings are often very small and of irregular shapes. Classification techniques that work for larger metal pieces are not always effective for these small shavings.

- Contamination and coatings: Many metal shavings are contaminated with oils, paints, or plastic coatings used during manufacturing processes. These impurities must be removed before recycling.

- Detection and technological repair: The accurate identification of different types of metal shavings requires very advanced technology. Systems based on artificial vision and sophisticated sensors are essential to distinguish between different types of metals. Highly sensitive, precise, and effective systems are needed.

- Specific recycling processes: Once identified and separated, the different metals require specific recycling processes. Multiple processing streams in a recycling facility are needed to process different types of metal flakes.

- Economic and energy efficiency: Maximizing the recovery of valuable metals from metal flakes while minimizing energy use and operational costs is a demanding challenge. Recycling facilities must balance process efficiency with economic viability.

- Environmental Regulations: Compliance with strict and ambitious environmental regulations in metal processing and recycling also adds complexity.

Minimizing environmental impact

Metal waste can pose serious risks in landfills and the natural environment if not properly managed. Metal waste, especially when it includes heavy metals, is difficult to decompose and can release toxic substances into the soil and water, affecting both ecosystems and human health. Heavy metals such as lead, mercury, and cadmium, can seep into the soil and reach groundwater sources. Cleaning and recovering soils contaminated by metal waste is a technically delicate process with high economic costs. For all these reasons, efficient separation and classification, recycling, and safe reuse of metal waste are crucial, and advanced technologies such as those developed by PICVISA play a vital role in the effective identification and separation of metal flakes, contributing to mitigating environmental and health risks and enhancing the valorization of this type of waste.

Metal recycling in the circular economy

Metal recycling in Europe is crucial in the transition to a circular and sustainable economy.

Within the European Union’s Environmental Agenda, metal recycling is a cornerstone for reducing dependence on virgin raw materials and minimizing the environmental impacts associated with mining and the production of new metals.

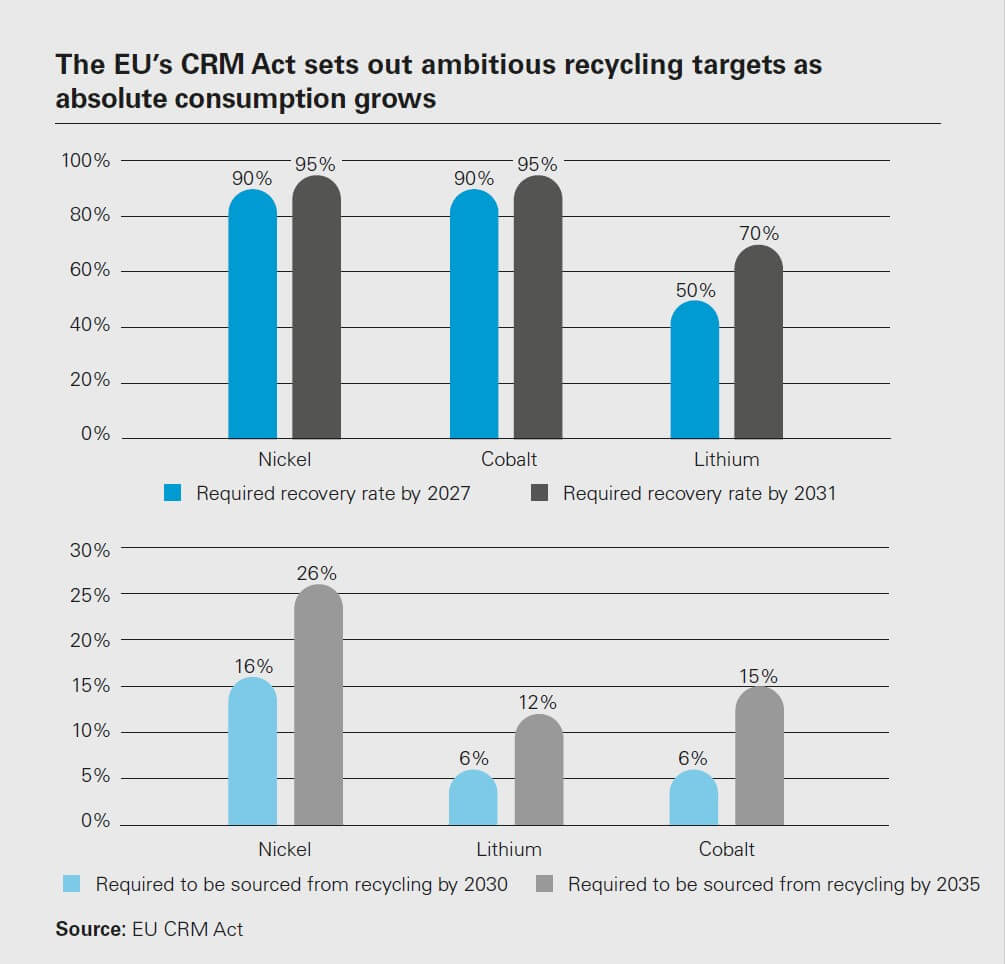

The recovery of metals such as lithium, nickel, and cobalt, considered strategic resources, tops the priorities of EU environmental policies, which have set very ambitious recovery and recycling targets.

By efficiently recycling metal waste, not only are valuable and increasingly scarce resources conserved, but the carbon footprint is also significantly reduced, contributing to a more sustainable future.

Parallel to the increase in efforts to achieve the best possible selection and recycling system for metal waste and critical raw materials, Europe is investing in developing hydrogen as a clean and sustainable energy source. In the steel industry in particular, green hydrogen offers an alternative to reduce the carbon footprint, demonstrating how innovation in clean energies and metal recycling can work together towards a future with fewer CO2 emissions.

The path to greater efficiency in metal recycling and the adoption of green hydrogen as a widely used fuel is currently in a phase that presents economically and environmentally very attractive opportunities in Europe: the creation of jobs in the green sector, international leadership in sustainable technologies, and the consolidation of a robust circular economy.

Europe’s focus on metal recycling and the drive towards green hydrogen can serve as a model for other regions. The joint effort of the industrial ecosystem and the political sphere not only drives environmental sustainability but also establishes new standards in the global economy.

From PICVISA, we continue to innovate and advance efficiency in the separation of metal waste, and other materials that are part of MSW, directly supporting the EU’s goals for a more circular and green economy.

About this Tech Article

This tech article appeared in Stainless Steel World, May 2024 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.