Executive Director of the NZSSDA, Paul Gapper, spoke to Stainless Steel World about the evolving role of the association and the vibrant stainless community in New Zealand.

By Joanne McIntyre

New Zealand boasts a vibrant stainless steel industry despite being a small and geographically isolated nation. The vital importance of the national dairy industry to the country’s economy has ensured that the level of stainless consumption and fabrication expertise is extremely high. Having transformed itself over the past four years, the New Zealand Stainless Steel Development Association (NZSSDA) is an information conduit for the local sector, finding and sharing the most relevant and timely information for its members.

The organisation encourages members to get involved in meetings and stay in touch with developments in the global industry. “We are an information provider for our members. Close relationships with associations such as worldstainless, the Australian ASSDA, and the Nickel Institute help to keep us up to date on issues relevant to our local members,” explains Paul Gapper, Executive Director at NZSSDA.

Uniquely New Zealand

Despite its relatively small size – its population is just five million – New Zealand has traditionally been one of the world’s highest consumers of stainless per capita, based on import statistics. “This is largely due to the dairy industry, which is massive in NZ,” explains Paul. “Over the years, many Asian mills and suppliers have used NZ as a test market for their products because our market is not too big, it’s a very open society to work in, and there are no import restrictions. These factors make us unique.”

“The amount of Grade 316 we use is proportionally higher than in many other countries because of the coastal nature of New Zealand. Overseas mills are often surprised how much more 316 we need compared to 304, but that’s the nature of the environment.”

Massive dairy industry

The dairy industry is New Zealand’s biggest export earner, with annual exports of approximately NZD 17 billion. The industry accounted for 20% of the country’s total exports and around 20% of revenue between 2004 and 2020.

“An enormous amount of stainless steel has gone into state-of-the-art dairy factories, milk powder plants, cheese factories, etc all over the country.

The maintenance market for these is, of course, a significant consumer of stainless as well,” explains Paul.

“New Zealand is a very open society to work in, and there are no import restrictions.”

“New Zealand is a very open society to work in, and there are no import restrictions.”

Paul Gapper

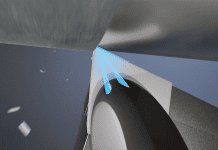

Geothermal power

Another significant stainless consumer in New Zealand is geothermal power. “New Zealand is the fifth largest megawatt producer of electricity using geothermal energy, and we will exceed that position with the new projects coming soon. We’re fortunate in that our geological location on the “ring of fire” allows us to be a major beneficiary of geothermal energy, and as a country, we have the potential

to do more with it. It’s the perfect renewable energy, available 24/7. Downstream it can be utilised to make hydrogen and lithium, which is one of the reasons I suspect there will be a lot more investment in geothermal in the coming years.”

“Geothermal energy uses more stainless than other renewable energies. The grades used have moved to 316, but a reasonable amount of 2205, 2507, nickel alloys, and titanium are required, depending on the environment and especially the levels of H2S and chlorides present.”

Food processing

“New Zealand is also unique in that we don’t internally polish our stainless tubes, fittings and process vessels for the food processing industry; instead, we rely on the 2B finish under AS1528. This was originally a joint Australia / New Zealand standard which we continue to use. The 2B finish is critical to our dairy, wine and food processing industries, and we consume a great deal of 4mm to 8 mm 2B finished plate, particularly in two metres widths.”

The 2B surface is achieved by cold rolling, heat treating and pickling, followed by the application of a light rolling at the end to achieve a smooth and reflective sheen.

A long supply chain

“New Zealanders have become accustomed to facing supply chain challenges due to our remote geographical location,” continues Paul. “This has always been a challenge for our stainless distributors, but in the past three years, it’s become a degree harder. In the past, we had a mill lead time plus four weeks shipping out of Asia or eight from Europe; today, we can face 6-8 weeks shipping from Asia and up to 16-18 weeks from Europe.”

“To give a recent example: I purchased material from a European stockist, they packed and shipped the order, and it arrived three months later. There were some concerns about the packaging and in-transit damage. When the supplier queried how the customer had stored it, I told them they hadn’t; it just arrived two days ago! So the extreme nature of the supply chain challenges we deal with is probably fairly unique. As a result, a relatively high percentage of imports are air freighted for project completion, maintenance and breakdowns.”

All about relationships

Paul explains that the New Zealand market has gravitated towards Asia for its supply of stainless steel. “We are fortunate to have a very close relationship with Asian manufacturers, particularly in Taiwan. Our importers and end-users have a stronger business and social relationship with Taiwanese manufacturers than in any other country, mainly because we do business the same way; it’s all about relationships and the people involved. Those relationships have stood us in good stead over the years. Although we are a small market buying modest tonnages, we are well supported because we are very loyal customers, our orders are regular, and we focus on building personal relationships.”

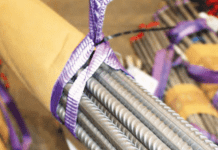

Potential for more duplex

The use of duplex stainless steel in New Zealand has increased in recent years, particularly in the food processing and dairy industries which have aggressive CIP (cleaning in place) systems.

“Duplex tubing and fittings to AS1528 is commonly used in those sectors; not huge amounts, but it needs to be available for that niche area. We commonly source our duplex from Australia and Singapore because, despite the growing demand, the relatively small volumes we need make it a challenge. I see enormous potential to increase the use of duplexes here. New Zealand is a very receptive and adventurous market; people like to try something different and explore the advantages. For example, I think LDX has great untapped potential in this market.”

Re-exports

The export of fabricated stainless steel equipment is a thriving industry in New Zealand. The nearby Australian market, which is five times the size of New Zealand, has historically been an important destination for high-quality processing equipment.

“Again, the dairy industry has played an important role in shaping our export capabilities, as our fabricators built up a broad base of knowledge and skills in producing high-quality turn-key equipment. For example, local companies manufacture cheese-making and vegetable processing equipment which is exported globally. Many such niches allow us to export stainless equipment, recognised internationally for its high quality and technological advancement.”

Future growth

Looking to future growth areas for stainless steel consumption in New Zealand, Paul highlights the considerable role water infrastructure will play.

“In terms of stainless steel, water infrastructure is an area where the local governments will invest in large projects in the coming years. Most growth will be around the supply of fittings, pipes and flanges: pipe sizes have increased over the years, and up to 1600-1800 diameter pipe has become more commonly specified. The NZSSDA has attempted to engage with water authorities to highlight the advantage of using stainless steel for domestic water supply, as reflected in recent projects by the Nickel Institute and Team Stainless. We’re in discussion with Water New Zealand, the industry body for users, suppliers, etc to encourage this type of change. We see our role as enhancing awareness of the material and providing whatever information they may need. There is huge potential!”

To learn more about the NZSSDA, please visit www.nzssda.org.nz

NZSSDA Blue Book

The NZSSDA Blue Book is a comprehensive, practical code of practice for fabricating with stainless steel, particularly for the food and dairy industries. It is fully accepted in the NZ industry and is often consulted when specifying materials in terms of quality, performance and longevity of plant and equipment. The content focuses on the practical aspects such as the handling, folding, machining, welding, designing etc of stainless steel. A new, updated edition will be released in 2023. Interested parties can email Paul Gapper at manager@nzssda.org.nz.

The NZSSDA Blue Book is a comprehensive, practical code of practice for fabricating with stainless steel, particularly for the food and dairy industries. It is fully accepted in the NZ industry and is often consulted when specifying materials in terms of quality, performance and longevity of plant and equipment. The content focuses on the practical aspects such as the handling, folding, machining, welding, designing etc of stainless steel. A new, updated edition will be released in 2023. Interested parties can email Paul Gapper at manager@nzssda.org.nz.

“New Zealand is a very open society to work in, and there are no import restrictions.”

“New Zealand is a very open society to work in, and there are no import restrictions.”