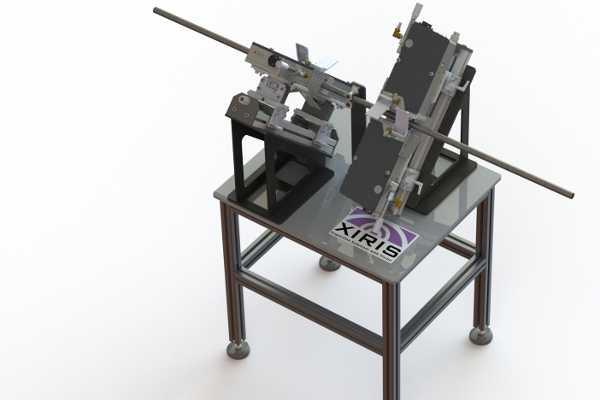

Xiris Automation Inc. has recently announced the development of the WI-2200-360° Scratch Inspection System, for tube and pipe manufacturing. The system is a combination of four laser triangulation sensors that have been specifically designed for the tube mill environment and are mounted around the tube to provide a full 360° inspection of coated and uncoated tube surfaces.

Protective coatings on metal tubing are critical to the overall performance of precision tubing. Ensuring that they are scratch-free is essential as surface scratches can provide a leak path for fluids in mission-critical applications. This requires both high-resolution sensors and powerful software algorithms for these minuscule scratches to be detected, which the WI-2200-360° Scratch Inspection System provides.

Some of the unique and beneficial features of this system include a very high precision vertical measurement resolution capable of detecting hairline-like surface scratches combined with advanced defect detection software incorporating a Class 2 laser system suitable for optimal operator safety.