AML3D is forging partnerships and establishing itself as a key supplier of large-scale metal AM for maritime applications.

Australian company AML3D saw an opportunity to adapt traditional arc welding technology and transform it into an additive manufacturing process that enables the freeform production of metal structures and parts. The company’s patented process, Wire Additive Manufacturing (WAM), has given this ability to a range of end users, most notably in the maritime industry.

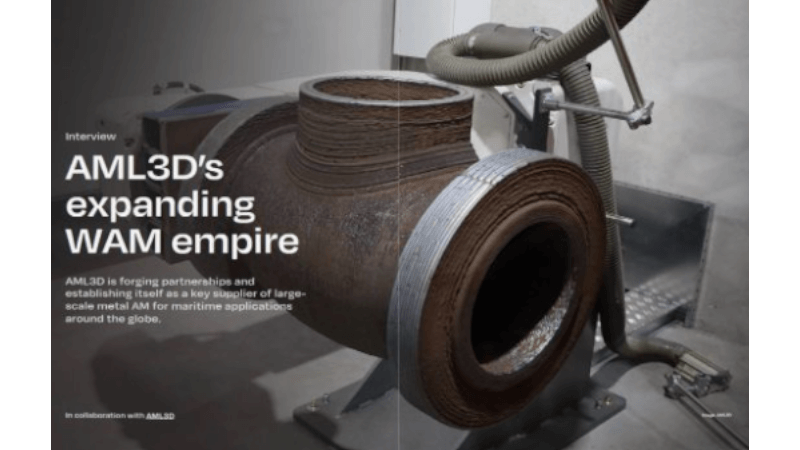

AML3D’s WAM process, commercialized through its ARCEMY platforms, rapidly and economically produces near-net-shape parts using an electric arc and certified welding wire feedstock. The nature of the process, which uses a localized inert gas shield, means that users are not bound by the size constraints associated with an enclosed build chamber, and can print large-scale, freeform parts safely and efficiently. Moreover, the DED-based technology is compatible with a wide range of materials, including exotic metal alloys. AML3D itself has tested over 30 different certified wire feedstocks, including aluminium, titanium, copper and nickel alloys, as well as steel and stainless steel.