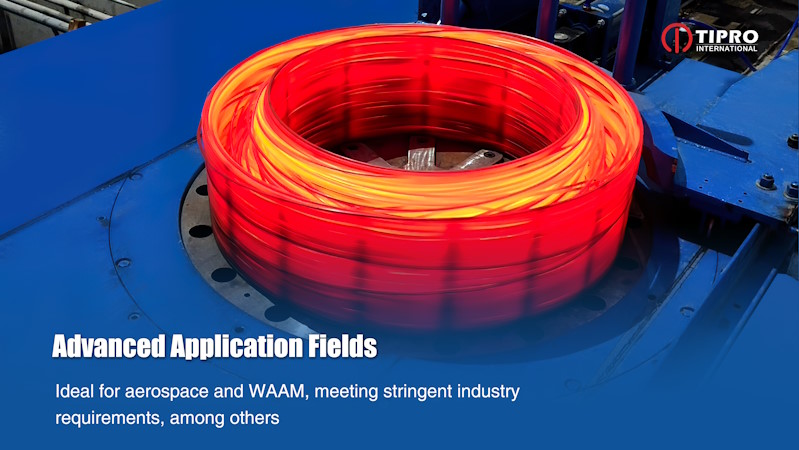

Tipro has successfully initiated trial production of titanium coils at its state-of-the-art rolling production line, achieving a significant milestone in large-scale titanium processing capabilities. The new production line specialises in manufacturing titanium coils with diameters of 5.0-5.5mm and unit weights up to 300kg, achieving 10μm grain size and 0.2mm ovality with uniform α+β phase distribution ensures superior material performance.

The advanced rolling system incorporates several key technological innovations including precision short-stress rolling technology ensuring dimensional stability, closed-loop temperature control for uniform microstructure, and automated coiling systems optimised for heavy-weight production.

Initial production results demonstrate full compliance with international specifications, including AMS 4928, AMS 4911 for aerospace applications, ASTM B348 for titanium alloy bars, and AMS 4954 for additive manufacturing.

The production process features comprehensive quality control measures such as 100% dimensional inspection, ultrasonic defect detection, mechanical property testin, microstructure inspection and full material traceability. Tipro expects to achieve full operational capacity by the third quarter of 2025, establishing new benchmarks in large-scale titanium coil manufacturing