As the world strives for climate neutrality, Carbon Capture, Utilization, and Storage (CCUS) is an essential bridge to a sustainable future. By capturing CO2 from industrial processes for storage or reuse, CCUS can prevent harmful emissions from reaching the atmosphere. The reliability and durability of this technology depend on molybdenum-containing materials.

By Iris Rommerskirchen & Nicole Kinsman, IMOA

Tackling the climate crisis and achieving net-zero emissions by 2050 is one of the greatest challenges of our time. Transitioning to renewable energy, improving energy effi ciency, and developing carbon-neutral technologies are crucial steps forward. In the interim, CCUS has emerged as a critical strategy for capturing CO2 emissions at their source.

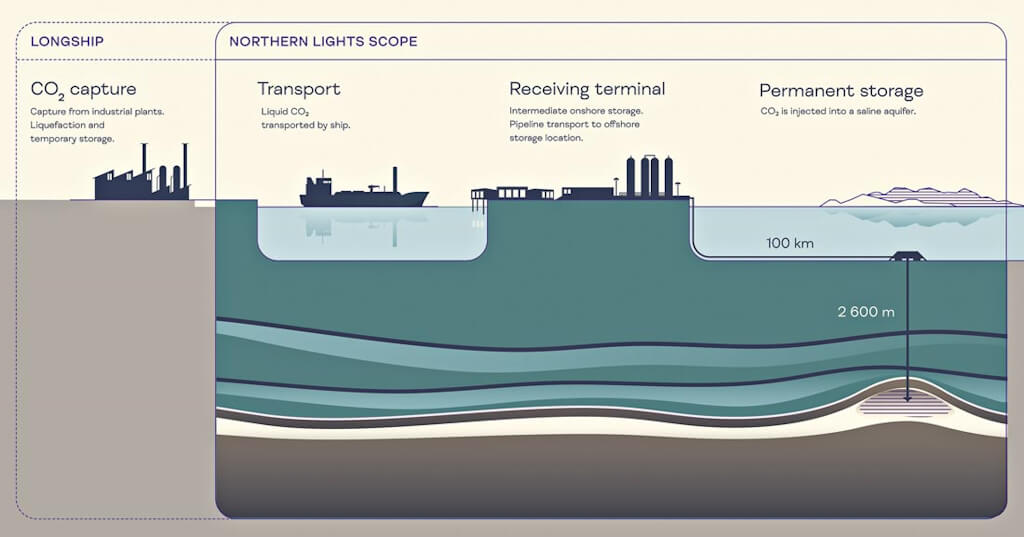

CCUS technology involves removing CO2 from the exhaust of industrial or power generation facilities and transporting it for storage or reuse. The CO2 is either securely stored underground – known as Carbon Capture and Storage (CCS) – or repurposed for industrial applications such as the production of chemicals, synthetic fuels, or building materials. This dual-purpose approach not only reduces emissions at the source but also reduces the need to extract virgin fossil fuels, further cutting emissions in downstream processes. However, the success of CCUS relies heavily on the quality and safety of its infrastructure, where molybdenum plays a critical role.

Barriers to decarbonization

Achieving full decarbonization remains a challenging process. Rising standards of living and increased digitalization mean that the global energy demand continues to grow despite the need to lower emissions. Carbon- and energy-intensive industries, such as steel production, are exploring solutions like replacing coke with hydrogen produced from renewable energy. While pilot projects are underway, it will likely take years before such practices become standard globally.

Other industries, such as glass manufacturing, ethanol production, power generation, hydrogen and ammonia synthesis, fertilizer production, natural gas processing, and various chemical processes, continue to emit CO2 even as efforts to decarbonize them intensify.

However, in some cases, CO2 emissions are unavoidable in specific chemical processes, like cement production in the concrete industry. Here, limestone is heated to 1500°C in coke-fired furnaces, and while the combustion of coke contributes to CO2 emissions, the majority – around two-thirds – comes from the release of CO2 stored within the limestone itself during calcination.

The challenges of handling CO2

While pure, dry CO2 is non-corrosive, captured CO2 in CCUS systems often contains impurities such as water, oxygen, and sulfur compounds.

During liquefaction, these impurities condense into corrosive acidic solutions, including sulfuric, nitric, carbonic, and hydrochloric acids, which can severely damage pipelines, storage facilities, and other CCUS components.

In addition to corrosion, sudden fluid depressurizations can rapidly cool liquid CO2 as it expands, sometimes to temperatures as low as -80°C – a phenomenon known as the Joule-Thomson effect. This rapid cooling introduces the risk of brittle fracture, a sudden and catastrophic failure of some materials due to their reduced toughness at low temperatures. Similarly, the subzero temperatures required for shipping liquid, impure CO2 present another scenario where brittle fracture becomes a significant concern.

To address these challenges, tougher materials without a ductile-to-brittle transition, such as austenitic and super austenitic stainless steels or nickel-based alloys, offer both the low-temperature toughness and corrosion resistance required. Duplex and super duplex stainless steels provide excellent corrosion resistance and have been proposed – and successfully used – for CO2 injection wells. Although they experience a ductile-to-brittle transition at subzero temperatures, they provide very high strength and are suitable for use under the given environmental conditions.

Carbon capture

Carbon capture isolates CO2 from industrial emissions using chemical absorption or similar techniques.

Post-combustion capture (PCC) units in fossil-fired power plants, for instance, use amine-based solvents like monoethanolamine to selectively absorb CO2 from flue gas. The PCC unit includes an absorption tower, where the solvent captures CO2, and a desorption tower, where heat releases the CO2 from the solvent for collection. The regenerated solvent is then recycled for continued use.

Unlike process-based carbon capture, which isolates CO2 from industrial emissions, direct air capture (DAC) removes CO2 directly from the atmosphere. This technology draws in air and passes it through a liquid or solid absorption medium. To prepare the captured CO2 for transport and storage, it must be released using heat and vacuum technology. DAC follows the same principles as other carbon capture methods for transport and storage.

The original concept for CCS involved integrating CO2 capture units with compression, transport, and storage systems directly within individual facilities, such as power plants, positioning them immediately behind emissions control systems. However, today, the preferred approach is the use of CCS networks known as “clusters”. In these networks, multiple CO2-producing sites are connected via a pipeline system that gathers CO2 from various sources and transports it to centralized separation, cleaning, and liquefying facilities. In this setup, molybdenum-alloyed, corrosion-resistant pipelines and equipment can be essential due to the varied and potentially corrosive impurities in the CO2 stream. By sharing infrastructure, CCS clusters reduce equipment costs for individual CO2 emitters.

Case study: Northern Lights joint venture (JV)

The Northern Lights JV, a partnership between Shell, Equinor, and TotalEnergies, is a CCS project designed to collect, transport and store CO2 from multiple sources. Four 7,500 m3 liquefied CO2 vessels will carry the CO2 to a receiving terminal in Øygarden, western Norway. The shipping technology adapts liquefied natural gas (LNG) transportation methods for CO2. At the terminal, where some systems are made of Type 316 stainless steels, the CO2 is temporarily stored before being transported via a 110 km offshore pipeline to a saline aquifer 2,600 m below the seabed for safe, permanent storage.

At the injection site, the bottom 200 m of the injection casing and tubing in the well are constructed from UNS S82551, a duplex stainless steel with 1% molybdenum, and UNS S39274, a 25Cr super duplex stainless steel with 3% molybdenum. These corrosion-resistant alloys are expected to withstand the aggressive conditions caused by temporary well closures, ensuring the long-term integrity of the well and the safe containment of CO2 deep underground. The diameter of the tubing and casing is up to 25 cm.

The project begins operations in 2025, with an initial capacity of 1.5 million tonnes per annum (Mtpa). Phase one will store 0.8 Mtpa of CO2 from a cement plant in Brevik, Norway, and a waste-to-energy plant in Oslo, as part of the state-supported Longship project. In addition, Northern Lights has entered commercial agreements to store 0.8 mtpa from Yara International’s ammonia production facility in the Netherlands and 0.43 Mtpa from two of Ørsted’s power plants in Denmark.

CO2 utilization

Carbon capture and utilization (CCU) complements CCS by repurposing CO2 as a feedstock for producing chemicals, synthetic fuels, and polymers. By using captured CO2 instead of hydrocarbons like natural gas or oil in chemical synthesis, CCU reduces the need to extract and process additional virgin fossil resources. Typical applications include the production of urea, salicylic acid, and polycarbonate.

CO2 can also enhance concrete production, where it is mineralized into carbonate, improving the material’s mechanical strength. Additionally, CO2 is widely used in the beverage industry for carbonating drinks.

Materials and components for CCS and CCUS

In addition to long-distance CO2 pipelines, typically made from submerged arc welded (SAW) carbon steels, CCS and CCUS facilities rely on a range of typical process industry equipment. Components made with molybdenum-containing stainless steels are essential to address corrosion concerns, particularly in the supercritical or liquefied state of CO2. According to “AMPP guide 21532”, Type 316 stainless steel could be considered for compressors and cooling devices, which are critical for densifying or liquefying CO2. The guide also mentions Type 316 stainless steel for onshore pipelines transporting dense or liquid-phase CO2 at temperatures as low as -80°C. Offshore and coastal pipelines, which are more exposed to chlorides, could benefit from 6% molybdenum or coated Type 316 stainless steel.

Other equipment, such as valves, flowmeters, and adsorption or desorption towers, also requires stainless steels. Alloy 625, a nickel-based alloy with 9% molybdenum, can be used for wellheads and trees where water flow-back and acidic condensates increase corrosion risks. At the same time, casings may rely on low-alloy, often molybdenum-containing steels such as L80 carbon steel, F22, or AISI 4130. Finally, well tubing may use 3.5% molybdenum-containing 25Cr super duplex stainless steel, which provides excellent strength and corrosion resistance.

State of the industry

The Global CCS Institute reports rapid growth in CCS projects worldwide, with 628 facilities in the pipeline by mid 2024 – a 60% year-on-year increase. These projects represent a cumulative CO2 capture capacity of 416 Mtpa, reflecting a seven-year compound annual growth rate of 32%.

Of the 50 facilities in operation, the United States leads in CCS deployment, with 19 operational facilities, followed by China with 14, Canada with seven, and Norway and Iceland with two. Australia, Brazil, Hungary, Qatar, Saudi Arabia, and the United Arab Emirates each have one operational project.

Europe has seen rapid growth, with the number of CO2 transport and storage facilities in development doubling over the past year to 77. This expansion highlights the increasing adoption of CCS technologies across the industrialized world.

While eliminating CO2 emissions remains the ultimate goal, some industries face emissions that cannot yet be avoided. CCUS provides a crucial pathway for capturing carbon and securely storing it underground or repurposing it for beneficial applications. The success of this transition depends on robust infrastructure, where molybdenum is indispensable for the resilience and durability needed to meet the challenges ahead.

About IMOA

Reproduced with the kind permission of the International Molybdenum Association (IMOA). IMOA is a non-profit trade association representing the majority of the molybdenum industry worldwide. For information visit www.imoa.info.

About this Featured Story

Appearing in the May 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.