Cutting narrow incisions with ultra-high precision in high-density materials using waterjet technology requires a specific waterjet cutting process: the Fine Abrasive Waterjet process (FAWJ). The first FAWJ cutting head was developed by Water Jet Sweden in 2008.

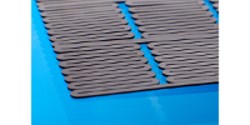

Waterjet cutting is a common method for processing parts in high-density materials such as aluminum, stainless steel, titanium, and carbon composites. The FAWJ cutting process bridges the gap between micro laser and EDM cutting and brings water jet cutting into the field of micro part processing.

To enable such levels of precision two things are required: (1) a cutting head and cutting process for FAWJ cutting and (2) a machine built for extreme accuracy. The NCM 10 Micro from water jet Sweden fulfills both of those requirements.

To reach the levels of accuracy required in micro part manufacturing, the NCM 10 water jet has a number of unique design features to create a rigid table that withstands temperature fluctuations: Mineral Casting Bearlit table frame; Rubber suspended stainless steel water catcher; and Renishaw Invar Scale in X and Y.