COGNE & DMV – together focused on the future

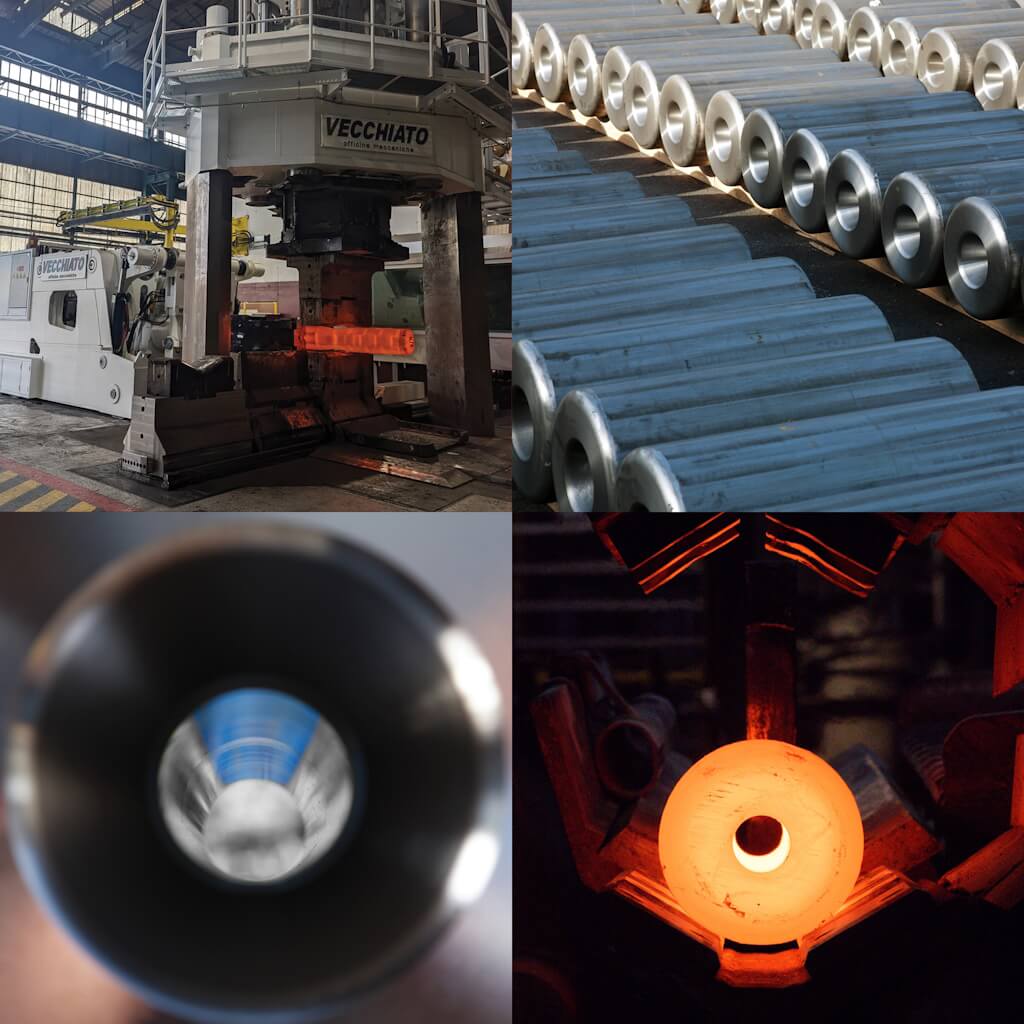

At the end of October, Cogne Acciai Speciali completed its acquisition of seamless tube manufacturer Mannesmann Stainless Tubes and relaunched it under the name DMV.

By embracing a name dating back to one of the most successful stainless steel tube collaborations the industry has ever seen, DMV is positioning itself for further growth in the warm embrace of its highly successful and rapidly expanding parent company. Stainless Steel World sat down with six key members of the Cogne and DMV teams to learn about the strategy behind the move and what it means for DMV and the Cogne Acciai Speciali Group.

Text by Joanne McIntyre, Stainless Steel World, images by Cogne Acciai Speciali Group

Strategic acquisitions

Cogne Acciai Speciali Group CEO Massimiliano Burelli begins with an overview of the many changes which have taken place recently. “Cogne Acciai Speciali (CAS) has over 108 years of history, dating back to 1916 when the Aosta plant was erected in Italy. Today it is a world leader in the production of long products in stainless steel and nickel alloys. I like to define us as a global company with a local touch. Since joining forces eighteen months ago, our shareholders, Walsin Lihwa Corporation and the Marzorati family, have embarked on an ambitious path of international development. Although the organisational changes have seen us grow into a Group with all the processes and procedures of a large multinational, our shareholders are controlled by individuals, so we retain the high-speed decision-making abilities of an entrepreneur. This enabled us to secure five acquisitions in a short time.”

These started in August 2023 when CAS acquired the Degerfors and Storfors facilities of Outokumpu Long Products AB in Sweden. The two steel rolling mills have been producing stainless steel round billets, hot rolled bars, and peeled bars for about 50 years. The acquisition strengthened the Group’s production efficiency and further consolidated the company’s position in the stainless steel market.

The next acquisition was Special Melted Products (SMP) in Sheffield, UK, which operates at the top end of demanding sectors such as aerospace, nuclear energy and oil and gas.

“SMP was very complementary to our activities,” explains Mr Burelli. “CAS was already active at the lower end of the nuclear and oil and gas sectors, and supplying aerospace material for items such as landing gear. The acquisition of SMP allowed us to enter the high end of the market, providing material and solutions for hot and rotating parts such as the struts supporting the turbine in jet engines.”

In May 2024, CAS bought 65% of Com. Steel Inox, the second largest scrap dealer in Italy. “This move secured the Group’s future needs for scrap while allowing us to process and integrate scrap generated in our newly acquired companies in Sweden and the UK,” continues Mr Burelli.

The most recent acquisition by CAS was that of Mannesmann Stainless Tubes (MST), which was finalised in October 2024. “This was an exciting acquisition because the tube market is new for us. It also meant we purchased a customer because CAS has supplied materials to MST for many years.”

“All of these acquisitions have strengthened our position by vertically integrating our operations in a multitude of ways and opening up new markets. One of our priorities was to increase our production output at the CAS Aosta plant in Italy significantly. At the start of this journey, we had some 30% of free capacity at Aosta; now it’s being filled up with the supply to Degerfors, SMP and MST.”

“It’s an exciting journey, and our teams have worked together fantastically to facilitate a lot of changes. An incredible amount has been achieved in a short time, and this was only possible because we have some very inspired shareholders who gave us the freedom to make proposals and make focused decisions very quickly.”

Improved competitiveness

Mariano Pizzorno, Executive Chairman of DMV GmbH, takes up the story. “DMV is back—strong, more competitive and a rewarding place to work. The new company moves forward with significant strategic advantages, including healthy financial support by our shareholders, upstream verticalization to secure availability and cost competitive supply of strategic raw materials, a sound brand, strong product portfolio, team knowledge and product quality.”

“Our core strategic pillars are:

- Health & safety

- Low-cost operations strategy

- Technology

- Carbon footprint

“We are already moving in that direction. Over the next several months, we will focus on improving our competitiveness by operating a lean manufacturing and supply chain process with strong ESG and sustainability by leveraging technology and increasing digitalization to holistically develop innovative R&D and manufacturing down-costing.

We can and will accomplish it. The people who will lead that charge are, for the most part, already at DMV. We plan to bring that same drive and commitment to innovation to DMV as we look to make it one of the leading companies again in our industry.”

18 months of expansion

November 2022 – Walsin Lihwa Corp becomes a 70% shareholder in Cogne Acciai Speciali (CAS)

August 2023 – CAS acquires the Degerfors and Storfors facilities of Outokumpu Long Products AB

September 2023 – CAS acquires Special Melted Products, UK

May 2024 – CAS acquires 65% of Com.Steel Inox S.p.A

October 2024 – CAS completes acquisition of Mannesmann Stainless Tubes along with its subsidiaries and operational facilities in Germany, France, Italy and the US, bringing the revenue of the Aosta-based steel mill to 2 billion euros and expanding the workforce to 3,100. The company is relaunched as DMV.

Iconic brands

Emilio Giacomazzi, DMV Managing Director, continues.

“The relaunch of MST as DMV is a historical moment as the creation of the original company in 1994 represented one of the best partnerships in the history of special steelmaking in the past century. Uniting DMV and Cogne now combines two iconic brands for seamless tubes and brings a sense of continuity. It was an obvious integration to combine a historical producer of seamless tubes with a steel mill to strengthen our presence in the market. It’s also a wonderful opportunity to integrate our production output because we have all the technology required to supply the vast majority of the range of steels DMV needs, from austenitic, super austenitic and super duplex to nickel alloys. The acquisition also integrates the ranges produced by Degerfors and SMP. This has produced an exceptionally strong team more than capable of successfully competing in an increasingly demanding market.” “Across the Cogne Group, we have strong environmental, social and governance (ESG) guidelines and a sustainability agenda. We will continue to focus on the core pillars of health and safety first, then low-cost operations. These will receive a huge impulse with the amalgamation of the skilled people, knowledge and facilities that this acquisition brings.”

Historical name

The name DMV originated in 1994 following the amalgamation of the stainless steel divisions of the Dalmine Group (Italy), Mannesmann Group (Germany) and Vallourec Group (France) under the name DMV Stainless. The DMV name ceased to be used in 2008.

Sales & application synergies

“From a purely sales point of view, DMV will benefit from CAS’s enormous sales and distribution network, which stretches across the continents of Europe, the USA, South America and Asia,” explains Christophe Le Rigoleur, Managing Director of DMV. “The network is supported by many metal experts, presenting a great opportunity to join our tube expertise, which is the DNA of DMV, with the metal expertise of the CAS factories and also with the expertise of SMP in the UK for nickel alloys and special grades.”

“There are also many application synergies where we can combine our forces; a good example is the mechanical industry, which is an important part of the DMV business. CAS has made tremendous progress in penetrating various special applications in recent years, such as aerospace. With DMV’s factory in France specialising in aerospace, we’ve already identified obvious synergies in combining our strengths for this sector.”

DMV also has opportunities to develop new products for market applications where Cogne already has a strong presence, such as the automotive industry.

“Both Emilio and I were present when the DMV brand was formed in 1994, so we both have a very strong attachment to it,” continues Mr Le Rigoleur with a smile. “During recent visits to shows in the Middle East and Asia, I was delighted at how well the brand is perceived by customers, several of whom expressed an interest in joining this journey with us. This shows the strength and reputation the DMV brand still enjoys in the industry with end users and distributors.”

Product development

Patrik Schraven takes up the story to explain the synergies for future developments. “These are based on the twin pillars of innovation and product development. For innovation, agility and speed are key topics we will address and work on to improve. Thinking outside of the box is a focus, together with flexible service offerings for customers beyond just selling tubes.”

“For product development, MST traditionally had a strong base with research centres all over Europe, and as DMV we will work closely with CAS’s network as well. Developments with key customers are ongoing and we will continue to create new products to meet future demand. Combining resources with CAS makes us stronger in terms of metallurgical science, and now we have steelworks to back that up.”

“Looking ahead, product development will focus on applications such as aerospace, medical, automotive and defence. These sectors will require new special nickel alloys, cobalt alloys and Maraging steels. This is a great chance for us to grow into markets that were previously limited to us due to the missing raw material base.”

Meet the team

The following people were interviewed for this article:

- Massimiliano (Max) Burelli, CEO, Cogne Acciai Speciali Group

- Mariano Pizzorno, Executive Chairman, DMV Group

- Emilio Giacomazzi, Managing Director, DMV Group

- Jörn Winkels, Managing Director, DMV Group

- Christophe Le Rigoleur, Managing Director, DMV Group

- Patrik Schraven, General Manager Marketing and Business Development, DMV Group

Looking to the future

Jörn Winkels, Managing Director DMV is keen to focus on the future.

“Looking forward, Europe and the US are in the midst of an industrial transformation. The main challenges we all face are the environment, climate change, rising costs, and skills and knowledge. Opportunities will arise for DMV by having a new owner who can supply our raw materials, and together, we will ensure the transformation succeeds. We’re very focused on aligning every process step with the requirements for the future. We are also aligning our administration and operational processes with the market and will make targeted use of artificial intelligence and new technologies to achieve our goals.”

“We are actively transforming the supply chain across the entire value chain with a focus on quality and costs. Across the company, we are already implementing a comprehensive program of measures to optimise and expand the existing network of our plants.”

Positive outlook

“Today’s macroeconomic environment, especially in Europe, is somewhat depressed, and this is affecting the steel market,” adds Mr Le Rigoleur. “The launch of DMV and our new journey with the Cogne Acciai Speciali Group creates a lot of positive momentum, which is unique to the industry. The Board of Directors and our staff are looking forward to the short, medium and long-term future. It’s incredibly motivating for all of us.”

Mr Burelli continues: “Prior to the acquisition of MST, the Cogne Group had a staff of 2,100 and eight production facilities. MST added 1000 people and five plants, so in relative terms, that’s a very substantial addition. It is an honour for us to now have this important piece of Europe’s steel history as a part of our group.”

“CAS is a modern company with no bureaucracy and the ability to make decisions rapidly. In the future with DMV, we will continue to create the conditions for future success. It will be an inspiring journey as we strive to utilise the power of togetherness.”

About this Featured Story

Appearing in the December 2024 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.