A new technology which uses ionized air offers a cleaner alternative for metal working fluids and emulsions in parts manufacturing.

Text & images by Aurion

The disposal of used cutting fluids causes significant environmental contamination. The global annual consumption of cutting fluids is estimated to exceed 2 billion litres although the actual amount is assumed to be up to 10 times higher, as most are diluted before use. Cutting fluid treatment and their release to the environment leads to significant oxygen depletion and nutrient destruction in surface waters.

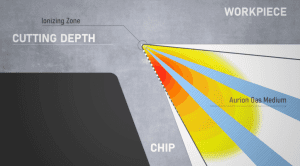

New technology developed by Aurion Machining Technologies Oy using ionized air provides a cleaner alternative for metal-working fluids and emulsions in parts manufacturing. The core of the technology is ionized air which generates an electrochemical process, resulting in electron loss and atomic level transformation of Aurion gas medium at the cutting surface.

The electrochemical process acts as a dry lubricant in the cutting process, penetrating the cutting zone and optimising the interaction between the tool edge and the workpiece.

This process accelerates oxide layer formation and significantly reduces friction, thermal stress and tool wear. The system consists of three components – ionizer, controller and air-cooling unit – and is connected to the factory compressed air network and machinery CNC. There is no need for any special safety precautions as ionized air pressure remains at 2 – 3 bar and temperature in the -10°C to +10°C during machining operations.

The new technology is the result of years of industrial research and development work. Its technical properties have been proven in thorough tests conducted by authoritative institutions and industrial partners. Most recently the respected Advanced Manufacturing Research Centre (AMRC) of the University of Sheffield in England achieved excellent results in titanium milling trials.

Economically compelling solution

The Aurion technology reduces manufacturing costs and lead times in workshop processes. Thousands of validation runs have proven it delivers at least the same machining quality and performance as cutting fluids – measured by cutting speed, tool life and surface quality. Ionized clean air is safe for its operators and the relevant machinery and meets the highest standards for workpiece residuals.

The Aurion technology reduces manufacturing costs and lead times in workshop processes. Thousands of validation runs have proven it delivers at least the same machining quality and performance as cutting fluids – measured by cutting speed, tool life and surface quality. Ionized clean air is safe for its operators and the relevant machinery and meets the highest standards for workpiece residuals.

Aurion technology is suitable for all machining applications and materials. It is easy to integrate to both existing and new machines, either by using the external piping to the cutting zone or by using existing coolant channels in standard toolholders and tools.

High integration flexibility and the possibility to use existing machine tool features minimises the up-front investment and limits the transition costs for introduction of the Aurion technology. The payback for the Aurion system is typically 3-6 months.

Moving to industrial scale

Following years of successful development work, Aurion is now ready for full scale industrial use. Attracted by the recent positive tests and validation runs, a number of high-quality manufacturers are engaged as partners in the next steps of the Aurion journey to transform their profitability and accelerate their carbon net zero plans.

About this Tech Article

This tech article appeared in Stainless Steel World, April 2024 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.